Method for processing bamboo strip

A processing method and technology of bamboo strips, applied in metal processing equipment, wood processing equipment, manufacturing tools, etc., can solve problems such as unfavorable environmental protection, rough surface of bamboo strips, waste of resources, etc., to improve processing utilization rate, simplify process flow, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of processing method of bamboo stick, the processing method that it adopts comprises following several steps successively:

[0019] (1) Fragmentation is carried out after bamboo is cut off as required, and bamboo chips are obtained after removing bamboo joints;

[0020] (2) the bamboo slices are further subdivided, and the bamboo green bamboo slices are separated from the bamboo yellow bamboo slices;

[0021] (3) obtaining bamboo strips after drawing the obtained bamboo green bamboo chips and bamboo yellow bamboo chips;

[0022] (4) bamboo strips are bleached;

[0023] (5) putting the bleached bamboo strips into a water mill for water milling, grinding off the bamboo strip surface, and cleaning;

[0024] (6) Put the bamboo strips cleaned by the water mill into a drying box to dry until the water content of the bamboo strips reaches 10%.

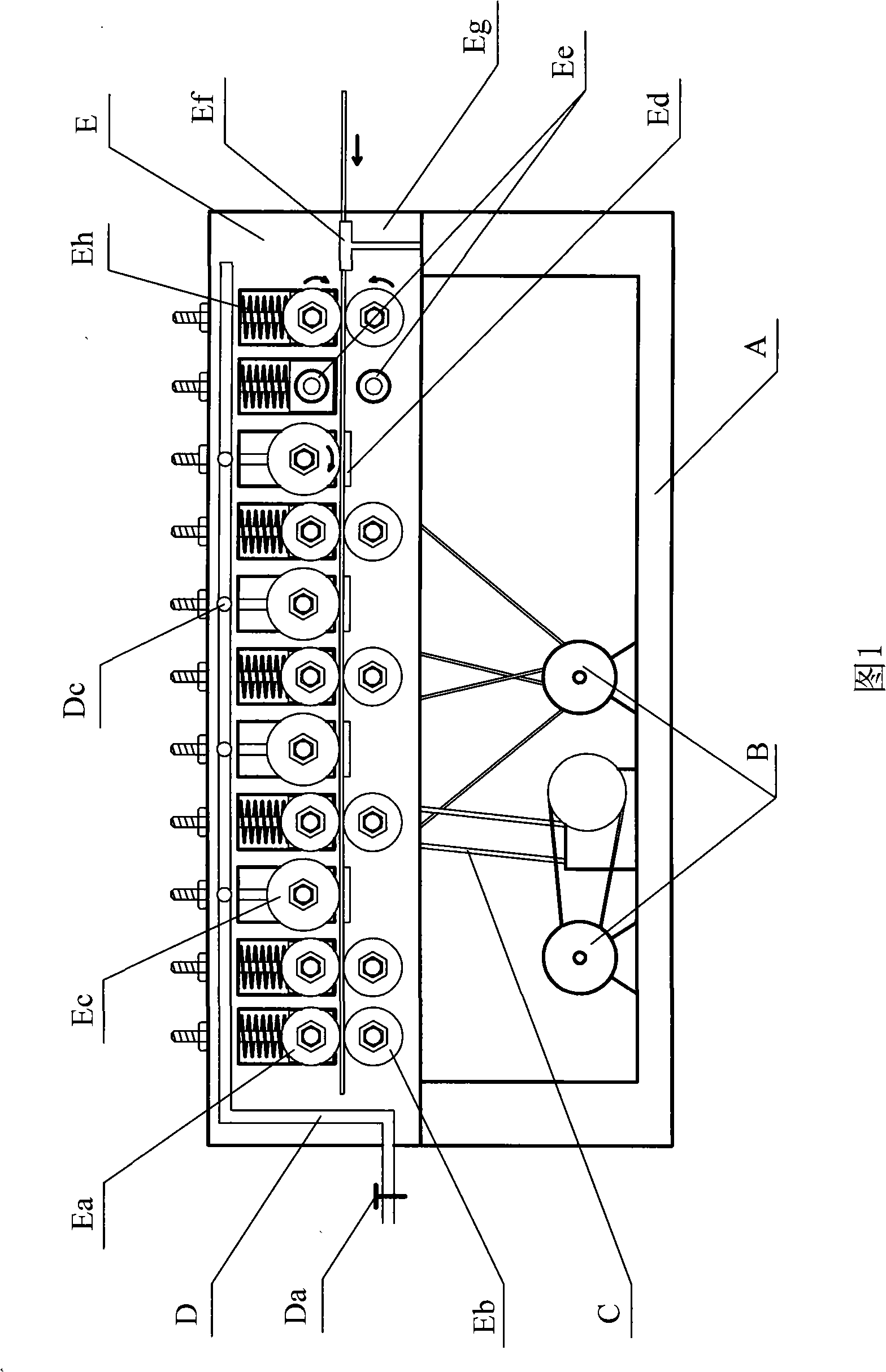

[0025] The water mill in the step (5) is composed of a base A, a motor B, a transmission part C, a water supply part D and ...

Embodiment 2

[0028] A kind of processing method of bamboo stick, the processing method that it adopts comprises following several steps successively:

[0029] (1) Fragmentation is carried out after bamboo is cut off as required, and bamboo chips are obtained after removing bamboo joints;

[0030] (2) the bamboo slices are further subdivided, and the bamboo green bamboo slices are separated from the bamboo yellow bamboo slices;

[0031] (3) obtaining bamboo strips after drawing the obtained bamboo green bamboo chips and bamboo yellow bamboo chips;

[0032] (4) bamboo strips are bleached;

[0033] (5) putting the bleached bamboo strips into a water mill for water milling, grinding off the bamboo strip surface, and cleaning;

[0034] (6) Put the bamboo strips cleaned by the water mill into a drying box to dry until the water content of the bamboo strips reaches 12%.

[0035] The structure and working principle of the water mill in the step (5) are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com