Vibration non-mesh screening machine

A technology of vibrating motors and mesh screens, which is applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of high cost and energy consumption, large volume, material blocking, etc., and achieve low manufacturing and use costs, and screening Simple equipment, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

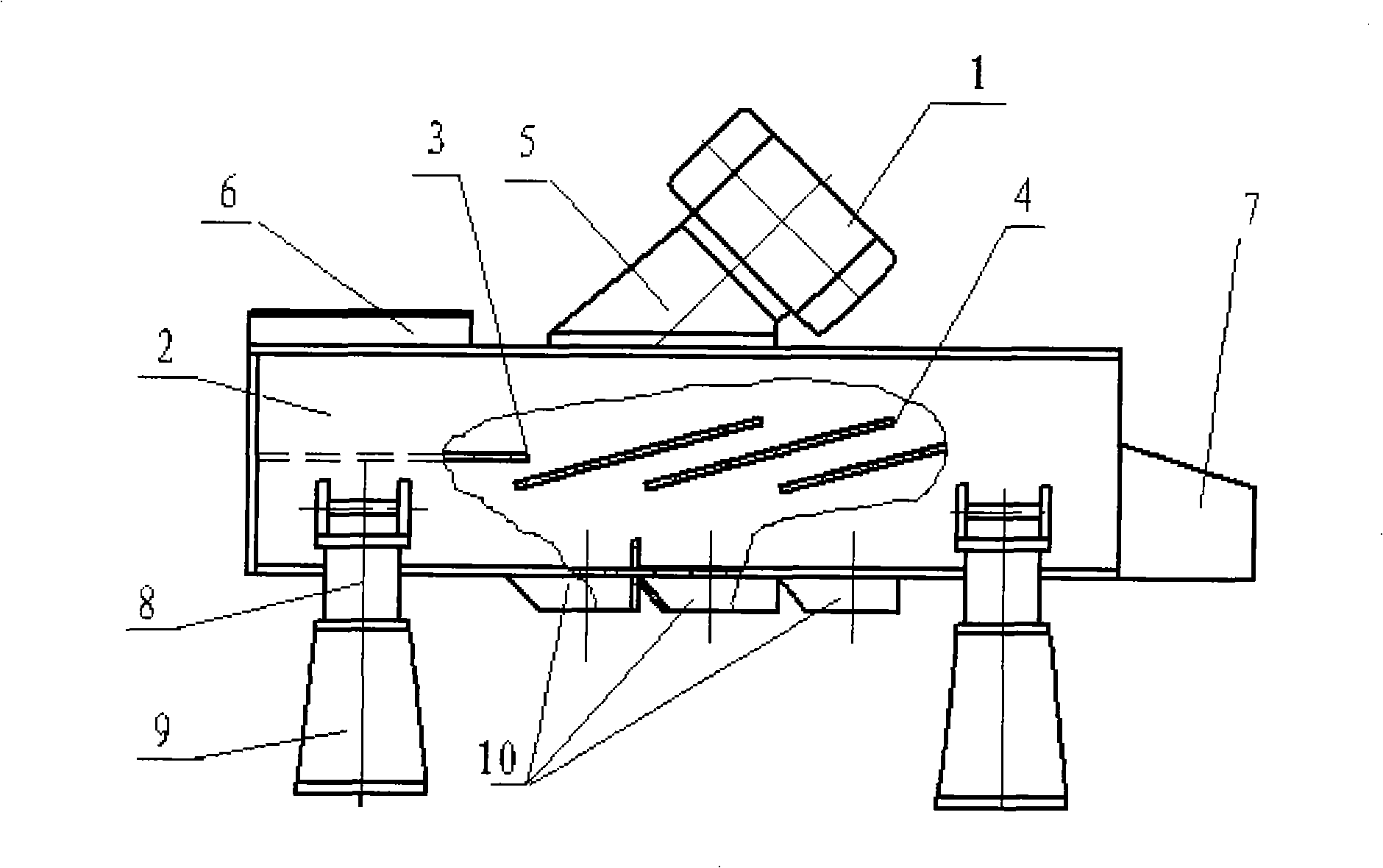

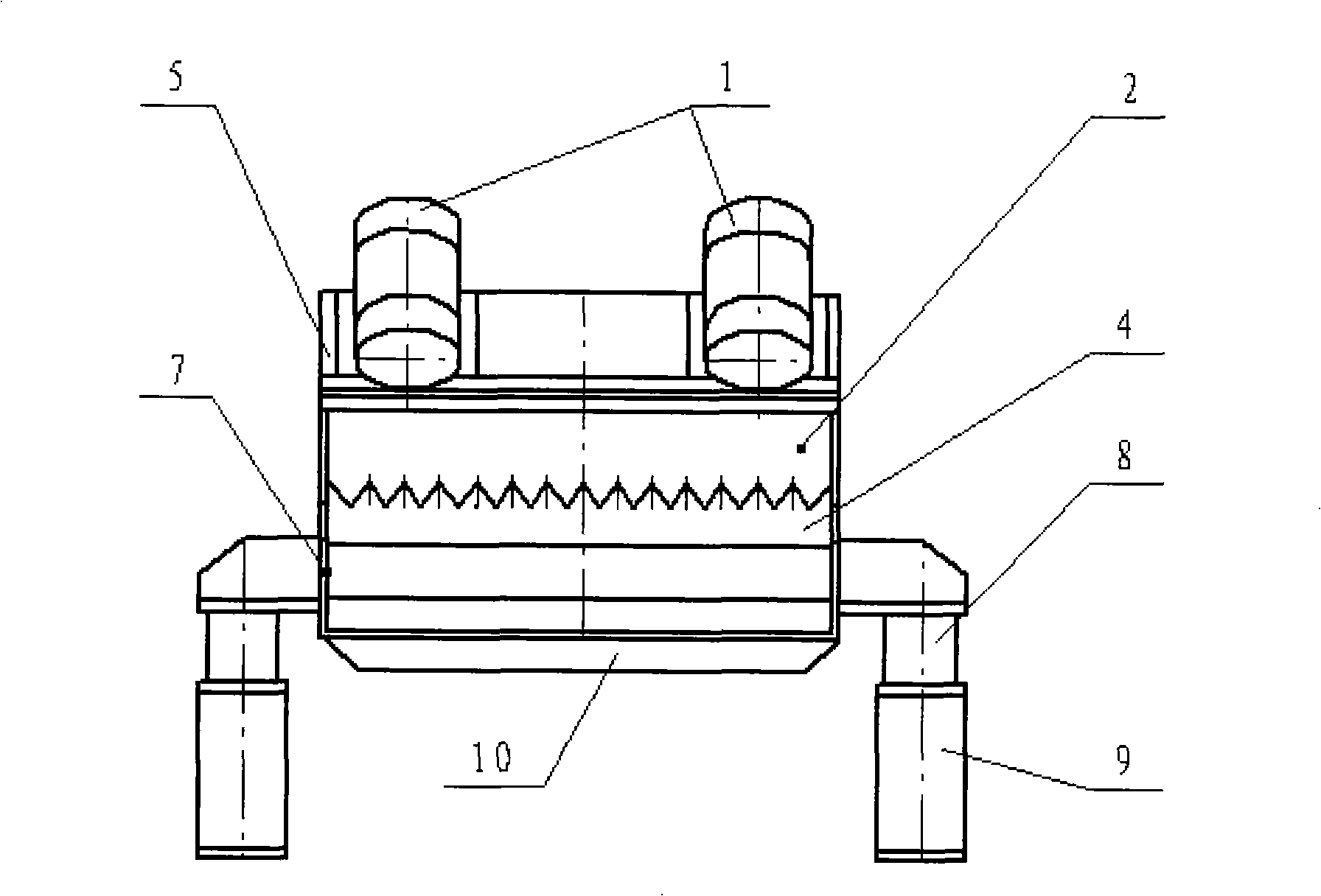

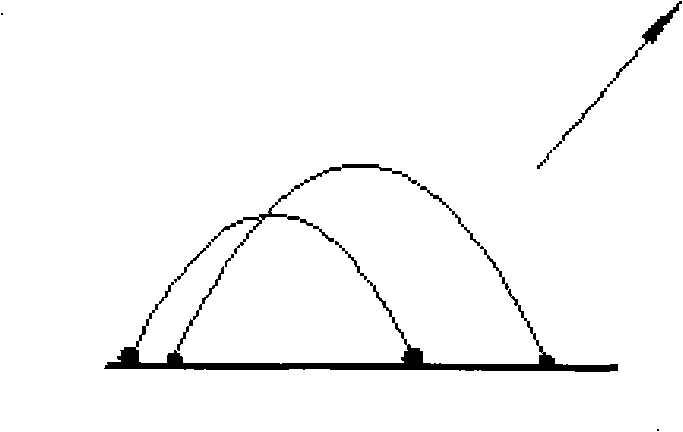

[0021] The vibrating meshless screening machine provided by the present invention is composed of a vibrating motor 1 , a vibrating sieve body 2 , a meshless feeding plate 3 and a meshless screening plate 4 . Such as figure 1 with figure 2 As shown: the vibrating motor 1 is installed on the motor support 5, and the vibration force acts on the vibrating screen body 2 through the motor support 5, and the shell of the vibrating screen body 2 is connected with the motor support 5 by welding and riveting. Inside the vibrating screen body 2, a non-mesh feeding plate 3 is installed at the feed port, and a plurality of non-mesh screening plates 4 with a certain upward inclination are evenly arranged and installed at other positions. The inclination angle is 5-25°. Above the meshless feeding plate 3 is a feeding port 6 connected to the left part of the shell of the vibrating screen body 2 . Below the meshless screening plate 4, there is a classification discharge port 10 correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com