Chitosan spherical honeycombed grain material, producing method and apparatus thereof

A technology of porous particles and spherical particles, used in dental preparations, pharmaceutical formulations, dental prostheses, etc., can solve the problems of high filling density, large diameter distribution of microspheres, and unfavorable growth of new tissues, and achieves favorable flow, Good particle size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) be that the acetic acid solution preparation chitosan quality of 1.5% with mass concentration accounts for the chitosan acetic acid solution of whole chitosan acetic acid solution quality 6%, stirring fully makes chitosan dissolve completely;

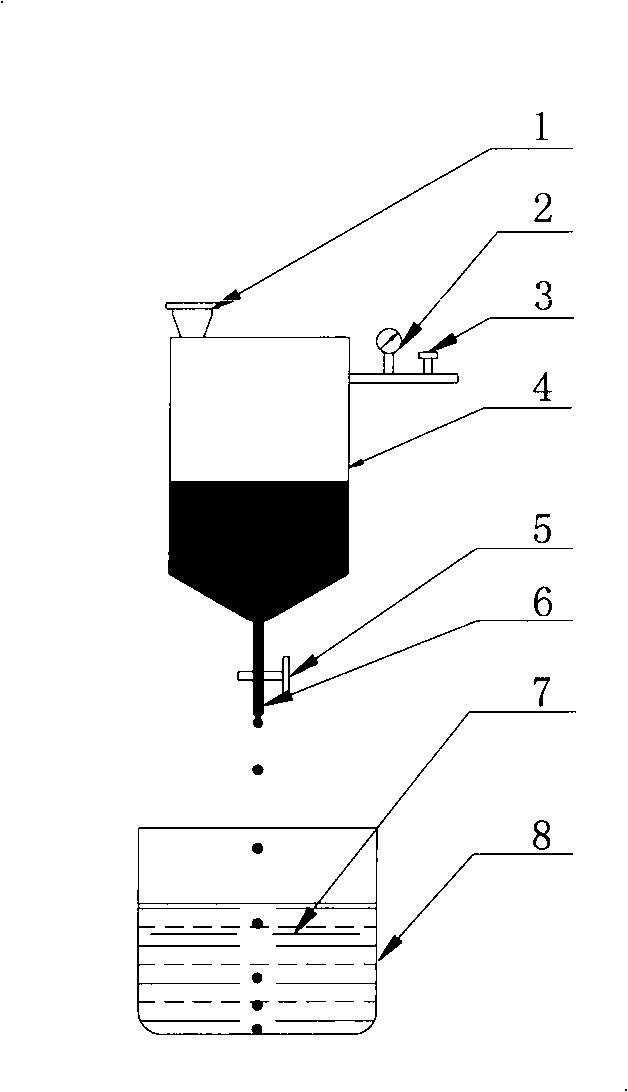

[0028] (2) if figure 1 Shown, the prepared chitosan acetic acid solution is added to the storage tank 4 from the feeding port 1, and the pressure in the storage tank 4 is controlled by a pressure control valve and a pressure gauge to be 0.08MPa to make the chitosan acetic acid solution from the pipe diameter of The catheter 6 of φ0.5mm flows out evenly at a speed of 10 drops / min, and the flow rate is controlled by the flow control valve. The chitosan acetate solution flowing out of the catheter grows to a nearly spherical shape of about φ0.8mm at the mouth of the tube. After the particles are dripped, they are dripped into the condensate 7 at a temperature of -10°C in the heat preservation container 8 to condense, and the con...

Embodiment 2

[0031] (1) be that the acetic acid solution preparation chitosan quality of 3% with mass concentration accounts for the chitosan acetic acid solution of whole chitosan acetic acid solution quality 25%, stirring fully dissolves;

[0032] (2) the prepared chitosan acetic acid solution is added to the storage tank 4 from the feeding port 1, and the pressure in the control storage tank 4 is 0.5MPa to make the chitosan acetic acid solution from the pipe diameter be the catheter tube 6 of φ 3mm Flow out evenly at a speed of 60 drops / min, and the chitosan acetic acid solution flowing out from the catheter grows to a nearly spherical particle of about φ4mm at the mouth of the tube and then drips. The condensate 7 is condensed to form a spherical particle material; the condensate is vegetable oil.

[0033] (3) The condensed microspheres are separated, and freeze-dried at a temperature of -10°C for 24 hours. The spherical particles after the freeze-drying are first put into a glyoxal so...

Embodiment 3

[0035] (1) be that the acetic acid solution preparation chitosan quality of 5% with mass concentration accounts for the chitosan acetic acid solution of whole chitosan acetic acid solution quality 15%, stirring fully dissolves;

[0036] (2) the prepared chitosan acetic acid solution is added to the storage tank 4 from the feed port 1, and the pressure in the control storage tank 4 is 0.28MPa to make the chitosan acetic acid solution from the pipe diameter to be φ 1.5. Tube 6 flows out evenly with the speed of 30 drops / min, and the chitosan acetic acid solution that flows out from catheter tube grows to the subspherical particle of about φ 2mm at the mouth of the pipe and then drips, and the temperature that drips in the heat preservation container 8 is- Condensation in the condensate 7 at 15°C to form spherical granular materials;

[0037] (3) The condensed microspheres are separated, and freeze-dried at a temperature of - (5 ~ 10) ° C for 14 hours. The spherical particles aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com