Internal circulation composite phase change heat exchanger

A phase change heat exchanger and composite phase change technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as unavailability of demineralized water, reduce steam turbine efficiency, destroy heat balance, etc. The effect of large heat absorption, improving output and thermal efficiency, and reducing exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

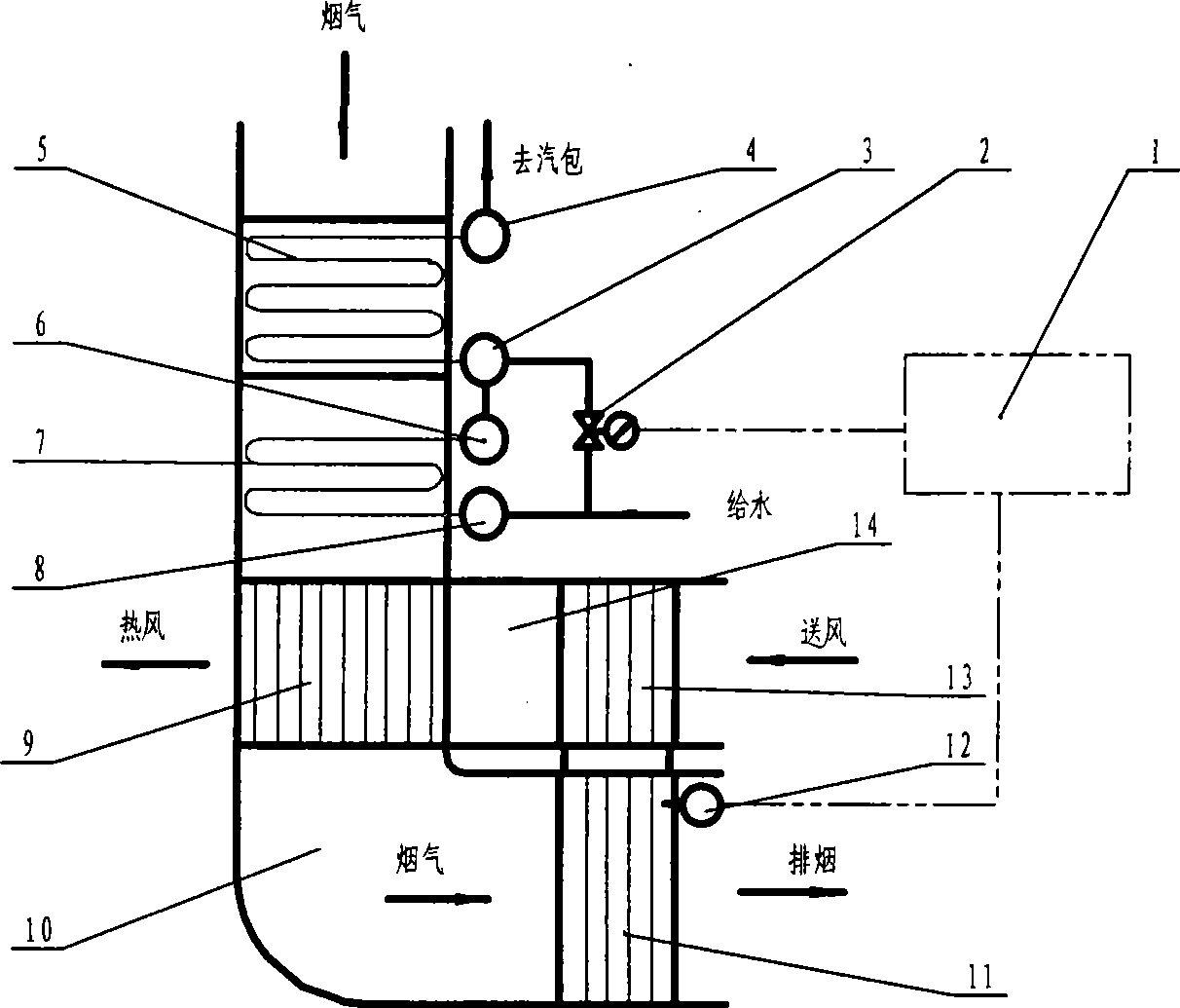

[0010] Further description will be given below in conjunction with the embodiments of the present invention and the accompanying drawings.

[0011] See the internal circulation composite phase-change heat exchanger shown in the accompanying drawings, there is a phase-change heat exchanger 13, 11 divided into upper and lower sections, and a new composite gas-water section 7, and a new composite gas-water section 7 It is located below the original economizer 5 in the flue 10 and is connected in series with the original economizer 5; the upper section 13 of the phase change heat exchanger is placed in the air duct 14 of the original air preheater 9, and the lower section 11 is placed in the air In the rear flue 10 of the preheater 9; the automatic control device 1 of the phase change heat exchanger adjusts and controls the heat exchange of the newly added composite gas-water section 7 and the wall temperature of the lower section 11 of the phase change heat exchanger. The boiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com