Well drilling gas injection joint and use method thereof

A drilling and gas injection technology, applied in drilling equipment, drill pipe, drill pipe, etc., can solve the problems of complex construction, high cost and high risk, achieve good gas injection effect, reduce pressure, and overcome the effects of complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Taking a drilling gas injection joint with an inner diameter of 142.08 mm and an outer diameter of 153.67 mm as an example, the present invention will be further described in detail.

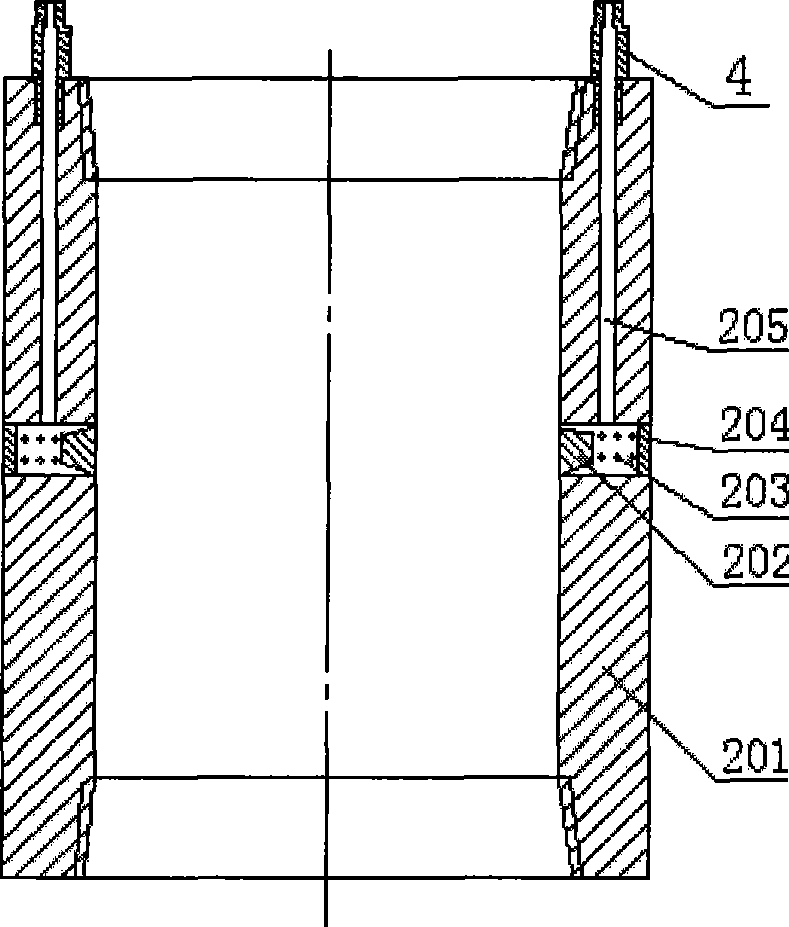

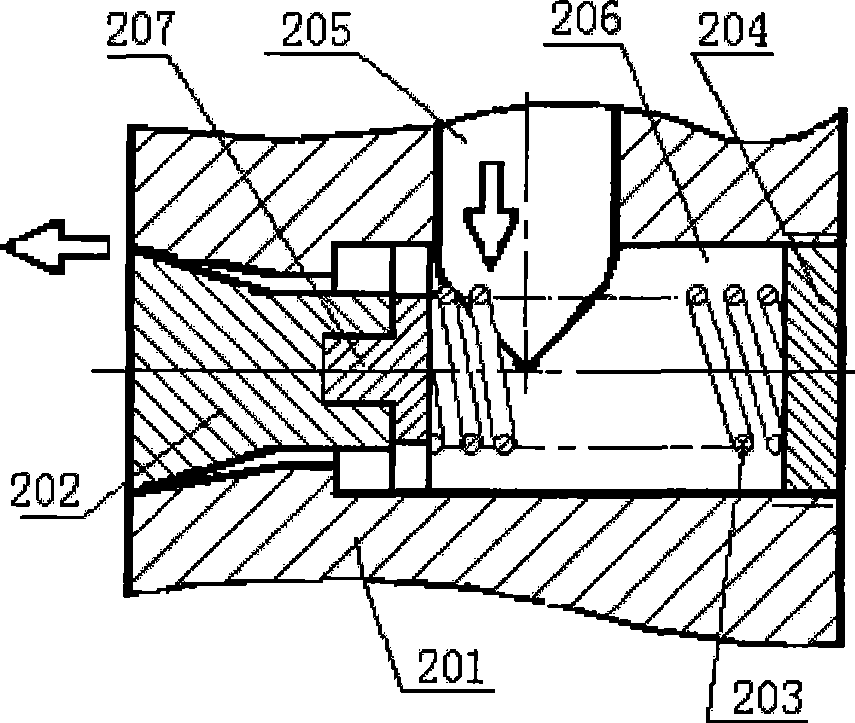

[0036] refer to figure 2. The drilling gas injection joint includes a body 201 , a tapered valve core 202 , a spring 203 , a plug 204 and a guide plate 207 . The body 201 is cylindrical, with an inner diameter of 142.08mm, an outer diameter of 153.67mm, and a length of 203.2mm. The steel material is J55 (API casing standard). The upper end and the lower end of the body 201 are provided with casing internal threads. The internal thread of the casing at the upper end and the lower end can be connected with the upper transition joint 6 and the lower transition joint 1 during the casing operation, the drilling gas injection joint is fixed in the middle of the casing string, and the casing string is run into the well at the same time.

[0037] Two longitudinal holes 205 are d...

Embodiment 2

[0041] Embodiment 2: Embodiment 2 is different from Embodiment 1: refer to Figure 7 . The valve core 202 is a plane valve core, and there is a gap at the edge of the plane valve core, and the high-pressure air can enter the casing through the gap. The circular hole at the inner end of the transverse hole 206 is a circular stepped hole.

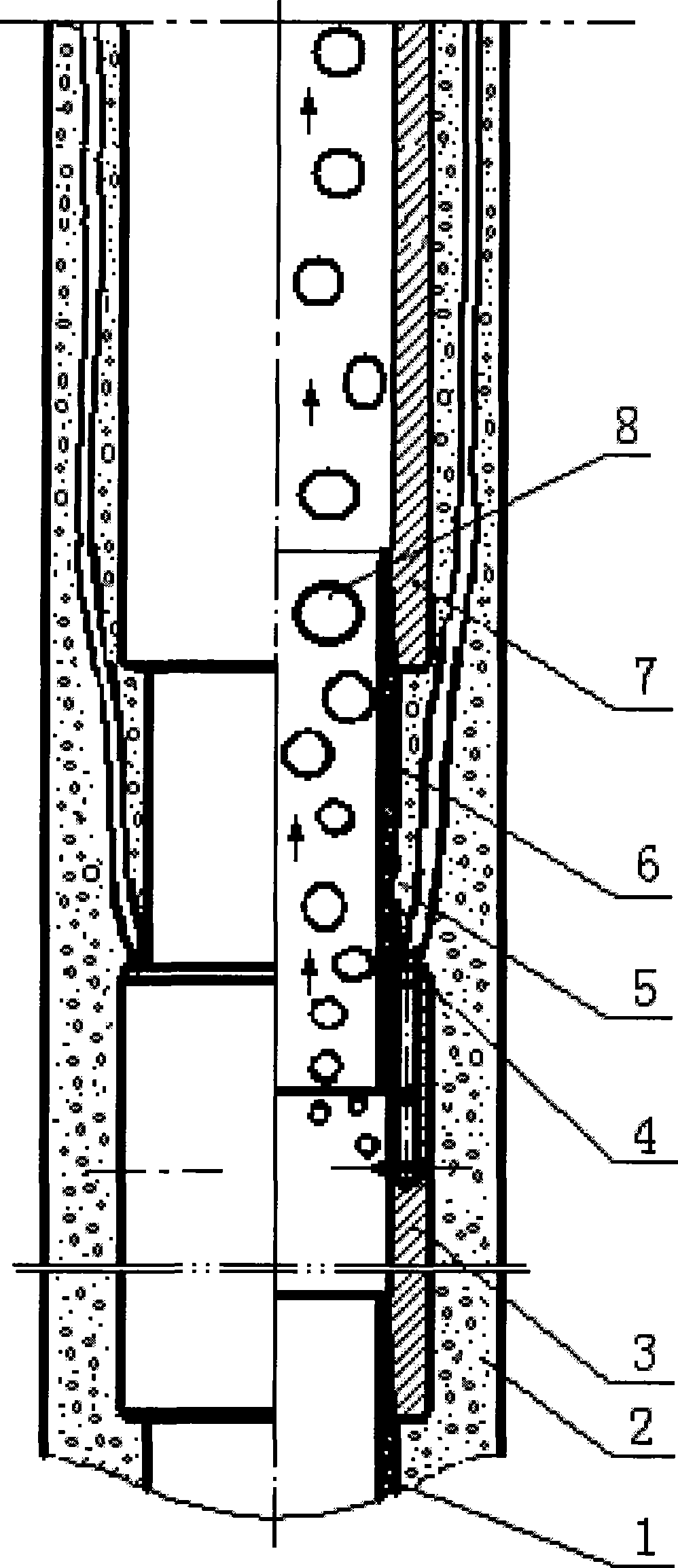

[0042] Example of using method of drilling gas injection joint: In a well with a second opening depth of 1100m, casing cementing is performed and underbalanced drilling is implemented. The working process is: see figure 1 .

[0043] A. Casing: after the second drilling is completed, the casing string with the drilling gas injection joint 3 is run in. A drilling gas injection joint 3 is connected to the middle part of the casing string. That is, the structure of the casing string is threaded from bottom to top with 400m of casing, a casing collar, a lower adapter 1, a drilling gas injection joint 3, an upper adapter 6, and a casing collar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com