Quick-speed generation method of anaerobic microorganism culture environment

An anaerobic microorganism and fast technology, applied in the field of bioengineering, can solve the problems of equipment difficult to meet the requirements of anaerobic bacteria cultivation, difficult to popularize application, expensive price, etc., and achieve the effect of low price, lower cost and faster response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

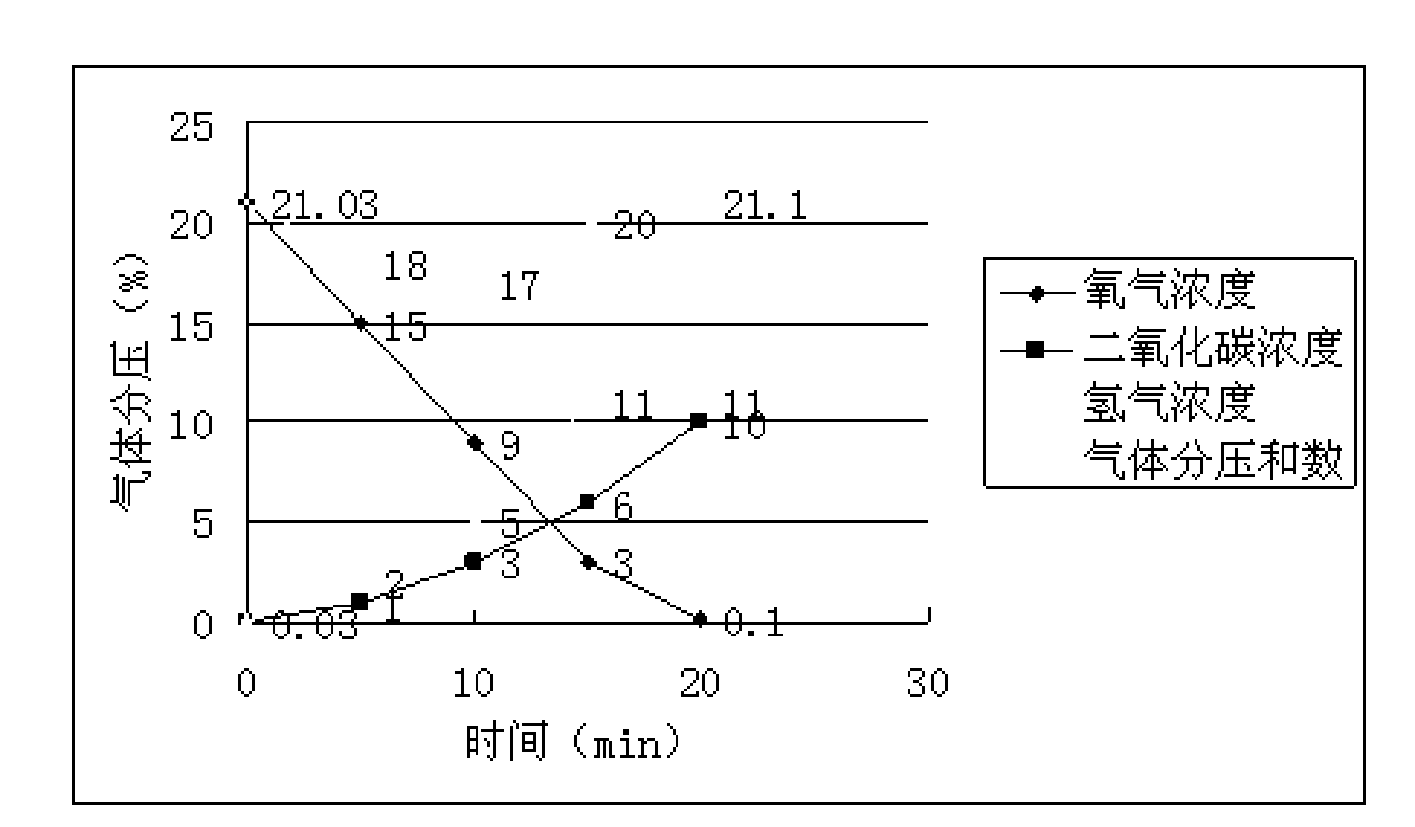

[0036] Clostridium putrefaciens CVCC96 was inoculated into bacterial thioglycollate medium, and Azotobacter sphaeroides CICC 20025 was inoculated into potato dextrose agar medium. The two inoculated culture media were put into a well-sealed and transparent box with a volume of 5.6 L, and a resazurin test paper was built in the box as an indicator of the redox state. Quickly add oxygen scavenger components, carbon dioxide generator components, and hydrogen generator components to the three preset containers in the box, and seal the box body. The entire process time is controlled within 2 minutes.

[0037] The oxygen scavenger components used are: 100 ml of 2.3 mol / L pyrogallic acid solution, 100 ml of 6.7 mol / L sodium hydroxide solution. The components of the carbon dioxide generating agent are: 100 ml of 0.25 mol / L sodium bicarbonate solution, and 100 ml of 0.091 mol / L citric acid solution. The hydrogen generator components are: 0.0275mol sodium borohydride and 100ml water. ...

Embodiment 2

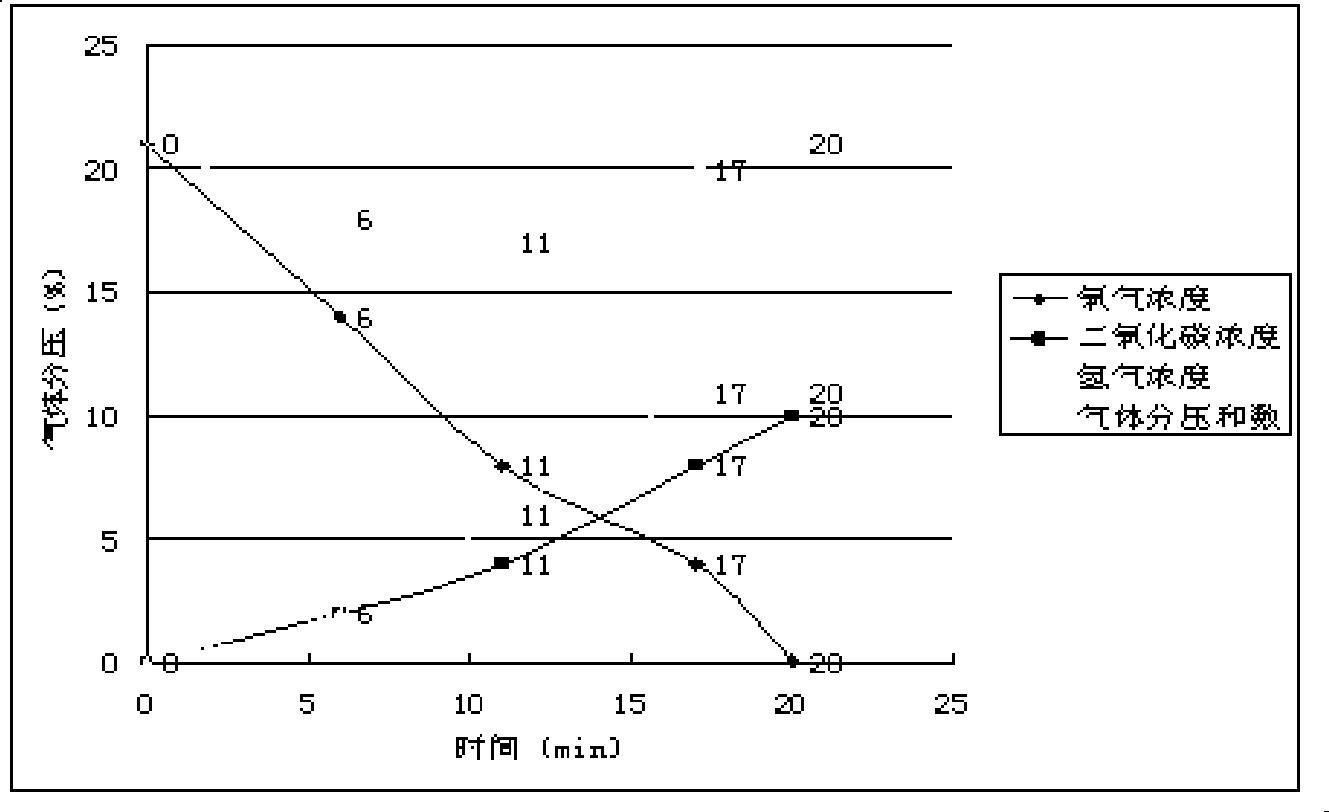

[0041]Example 1 was repeated in the same manner as described, but the oxygen scavenger auxiliary was simultaneously added to the vessel containing the oxygen scavenger component. The oxygen scavenger components used are: 100ml of 2.1mol / L pyrogallic acid solution, 100ml of 13.5mol / L sodium hydroxide solution, and the oxygen scavenger auxiliary agents are: reduced iron powder 0.0714mol, sodium chloride 0.025mol, activated carbon 0.1667 mol, carbon dioxide generating agent components are: 0.125mol / L sodium bicarbonate solution 100ml, 0.0455mol / L citric acid solution 100ml, hydrogen generating agent components are: 0.04mol sodium borohydride and 100ml water.

[0042] Through the determination of the oxygen concentration and carbon dioxide concentration in the box, the relationship between carbon dioxide concentration, residual oxygen concentration and time is established, see the attached figure 2 .

[0043] After 24 hours of constant temperature cultivation at 37°C, the result...

Embodiment 3

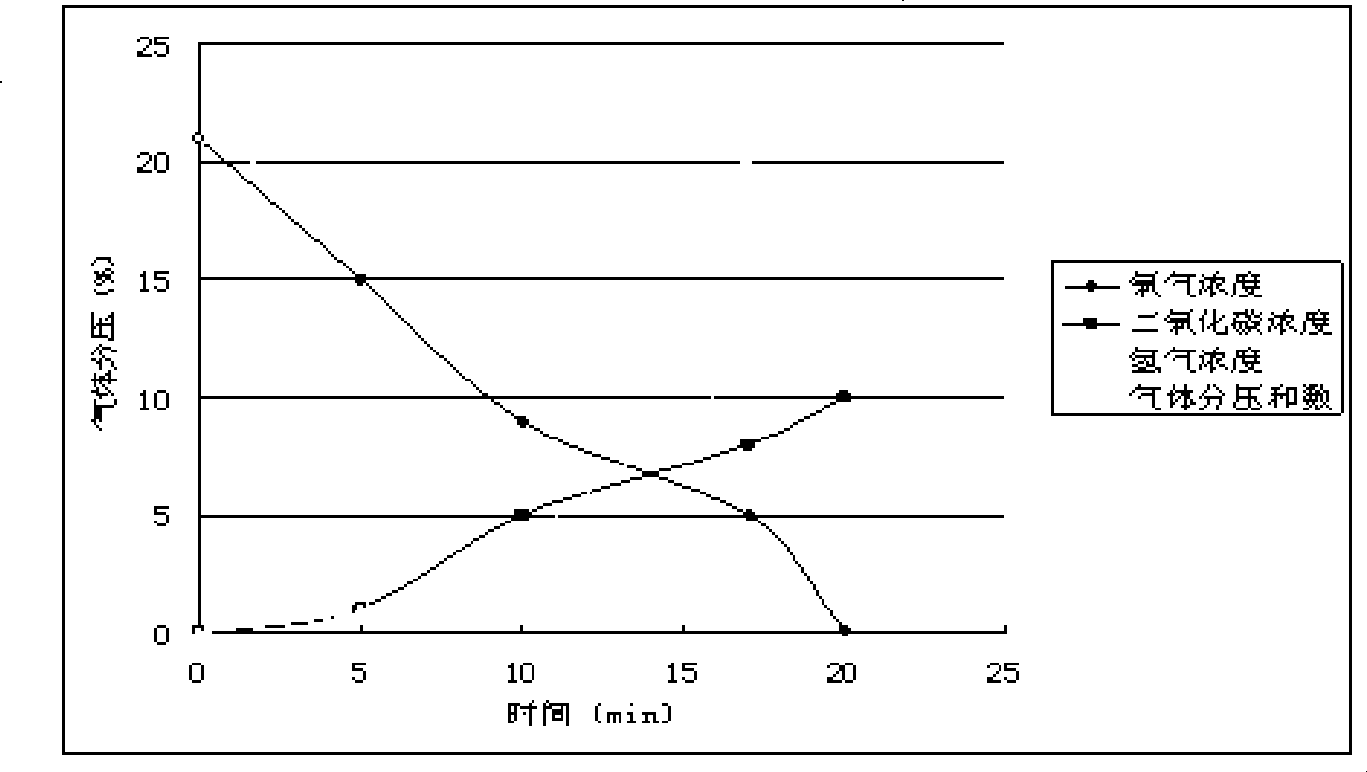

[0045] Example 1 was repeated in the same manner as described, but the oxygen scavenger auxiliary was simultaneously added to the vessel containing the oxygen scavenger component. The oxygen scavenger components used are: 100ml of 2.8mol / L pyrogallic acid solution, 100ml of 2.1mol / L sodium hydroxide solution, and the oxygen scavenger auxiliary agents are: reduced iron powder 0.0728mol, activated carbon 0.14mol, carbon dioxide generator components It is: 100ml of 0.2mol / L sodium bicarbonate solution, 100ml of 0.0728mol / L citric acid solution, and the hydrogen generator components are: 0.028mol sodium borohydride and 100ml water.

[0046] Through the determination of the oxygen concentration and carbon dioxide concentration in the box, the relationship between carbon dioxide concentration, residual oxygen concentration and time is established, see the attached image 3 .

[0047] After 24 hours of constant temperature cultivation at 37°C, the results of bacterial cell culture w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com