Preparation method of patterned slice

A manufacturing method and patterning technology, applied in chemical instruments and methods, techniques for producing decorative surface effects, decorative art, etc., can solve problems such as difficulty in passing hardness tests, low product yields, and non-wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments will be described in detail below together with the accompanying drawings.

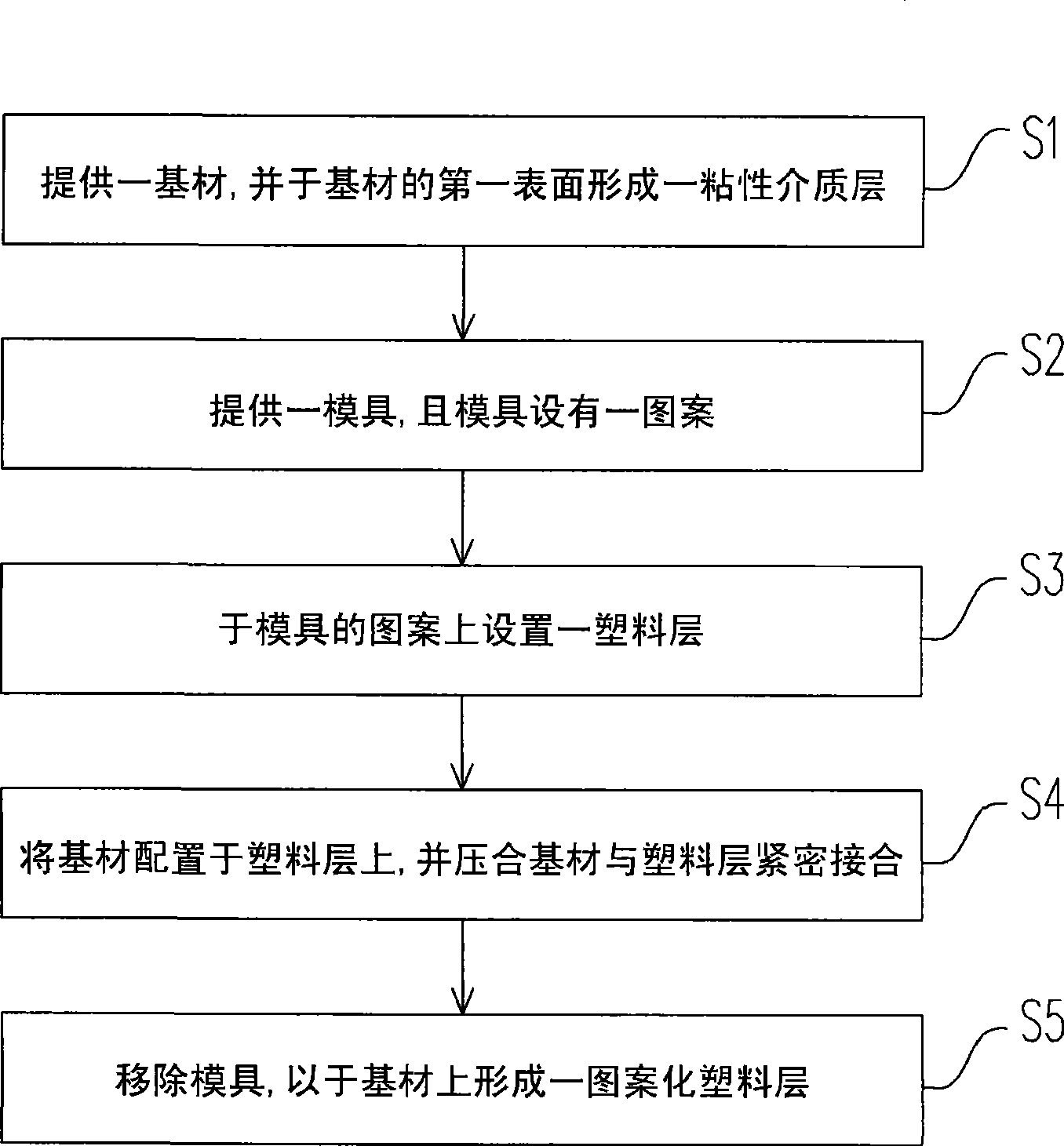

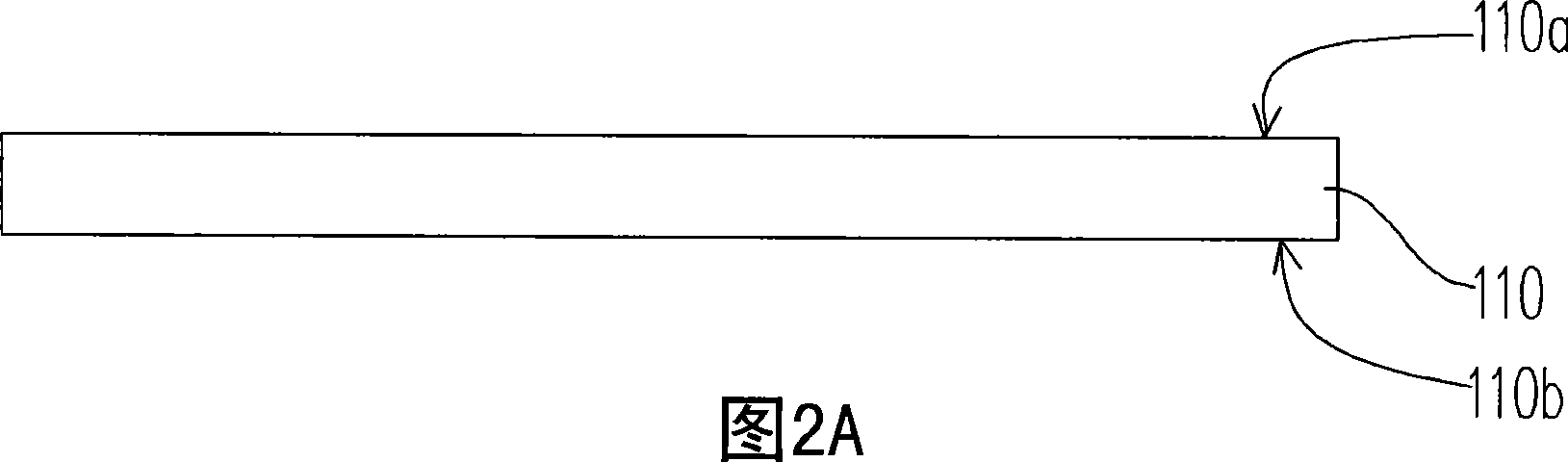

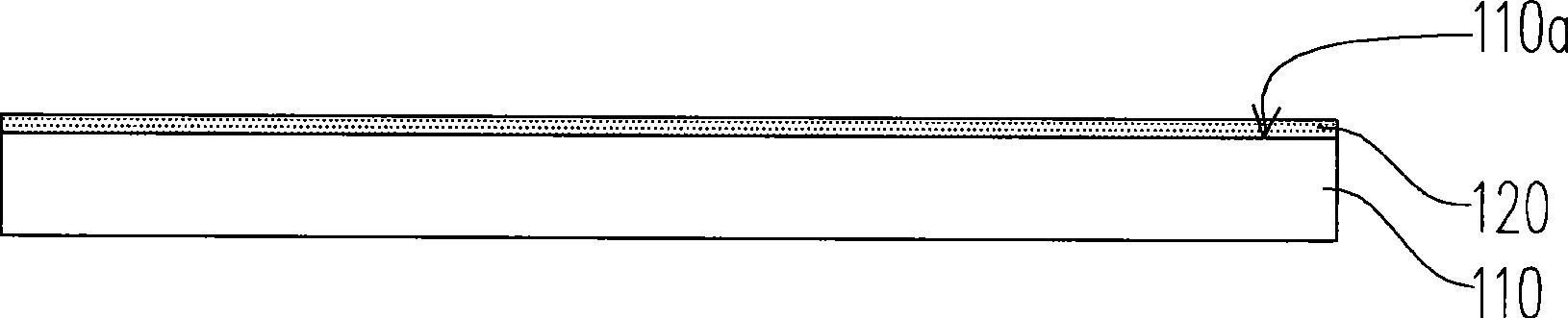

[0027] figure 1 It is a flowchart of a method for manufacturing a patterned sheet according to an embodiment of the present invention. The patterned sheet of this embodiment is, for example, a thin key sheet for a mobile phone, and its manufacturing method includes the following steps: First, step S1 is performed to provide a substrate and form an adhesive medium layer on the first surface of the substrate. Then, step S2 is executed to provide a mold, and the mold is provided with a pattern. Next, step S3 is executed to set a plastic layer on the pattern of the mold. After the plastic layer is set on the pattern of the mold, step S4 is then performed, disposing the base material on the plastic layer, and pressing the base material and the plastic layer toge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com