Method of etching cd pattern on the surface of substrate and laser cutting to form logo

A technology of substrate surface and laser cutting, applied in laser welding equipment, metal processing equipment, photoengraving process of pattern surface, etc., can solve the problems of affecting LOGO aesthetics, low processing accuracy, and high cost of CD pattern molds. To achieve the effect of lasting colorful effect, strong three-dimensional effect and good glare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

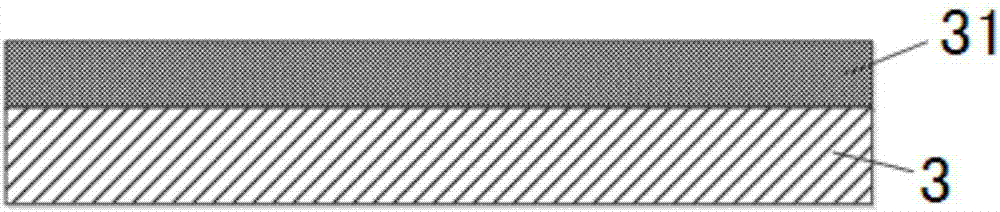

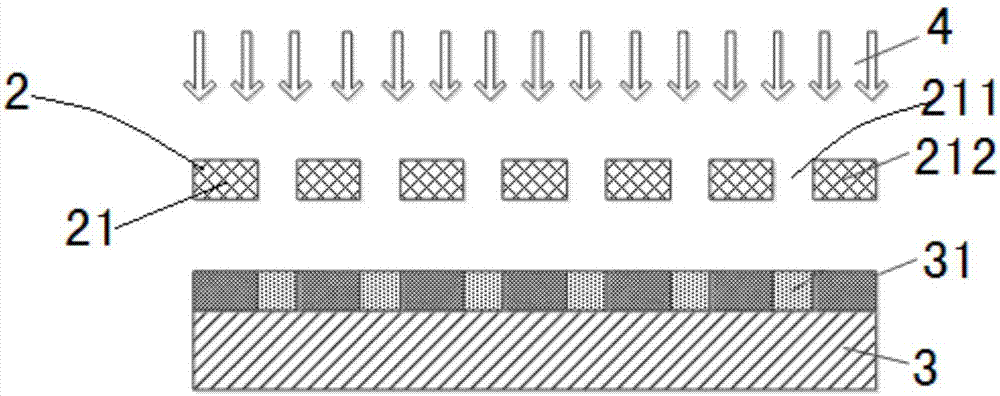

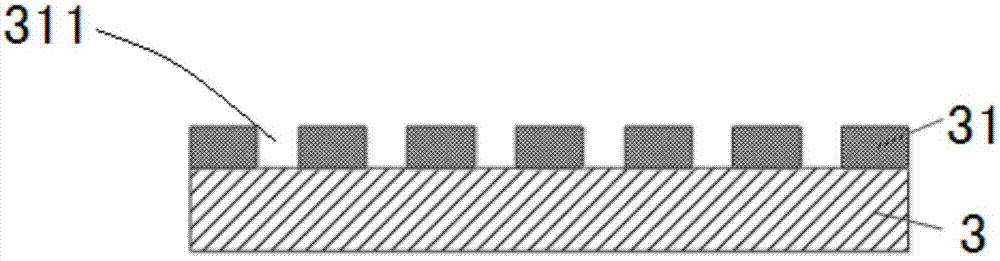

[0049] see Figure 1~Figure 15 According to the present invention, a method for etching and processing CD lines on the surface of a substrate and laser cutting to form a LOGO includes the following steps:

[0050] 1) Make a mask

[0051] According to the different specifications of the CD pattern 1 to be processed, the mask plate 2 is designed and manufactured according to the ratio of the area of the CD pattern 1: the area of the mask plate 2 = 1:1 or 4:1 or 5:1, and is formed in the middle of the surface of the mask plate 2 A CD pattern area 21 corresponding to the CD pattern 1, the CD pattern area 21 includes a light-transmitting area 211 and an opaque area 212;

[0052] Among them, there are currently three types of photolithography machines on the market, which are proximity or contact photolithography machines. The CD pattern area: mask area = 1:1, and this type will be selected when the line width and line space width are above 1 μm. Lithography machine; CD patter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com