System for and method of edge welding using projections

A prominent, marginal technology applied in the field of resistance welding systems to reduce energy consumption and improve maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

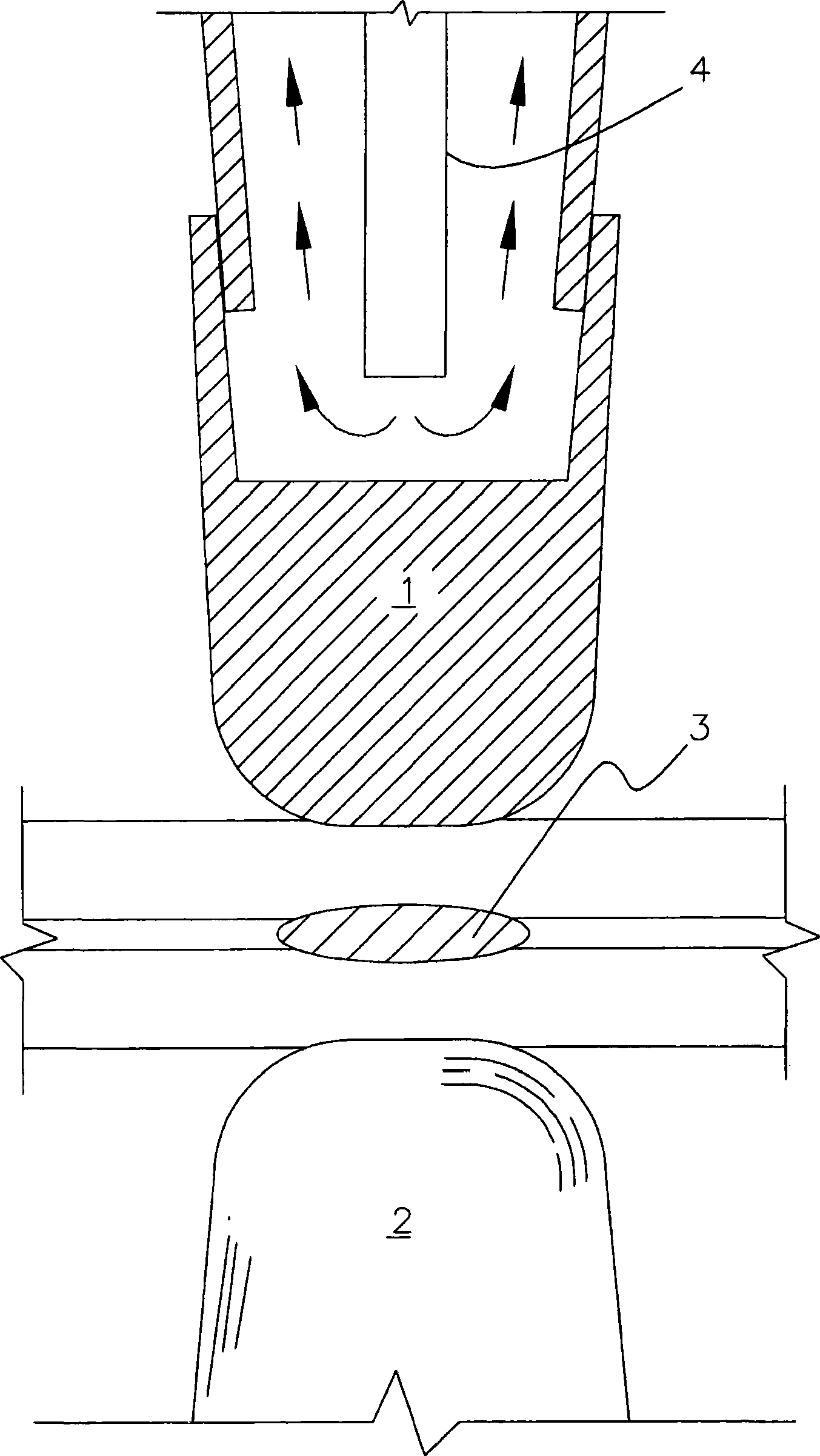

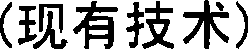

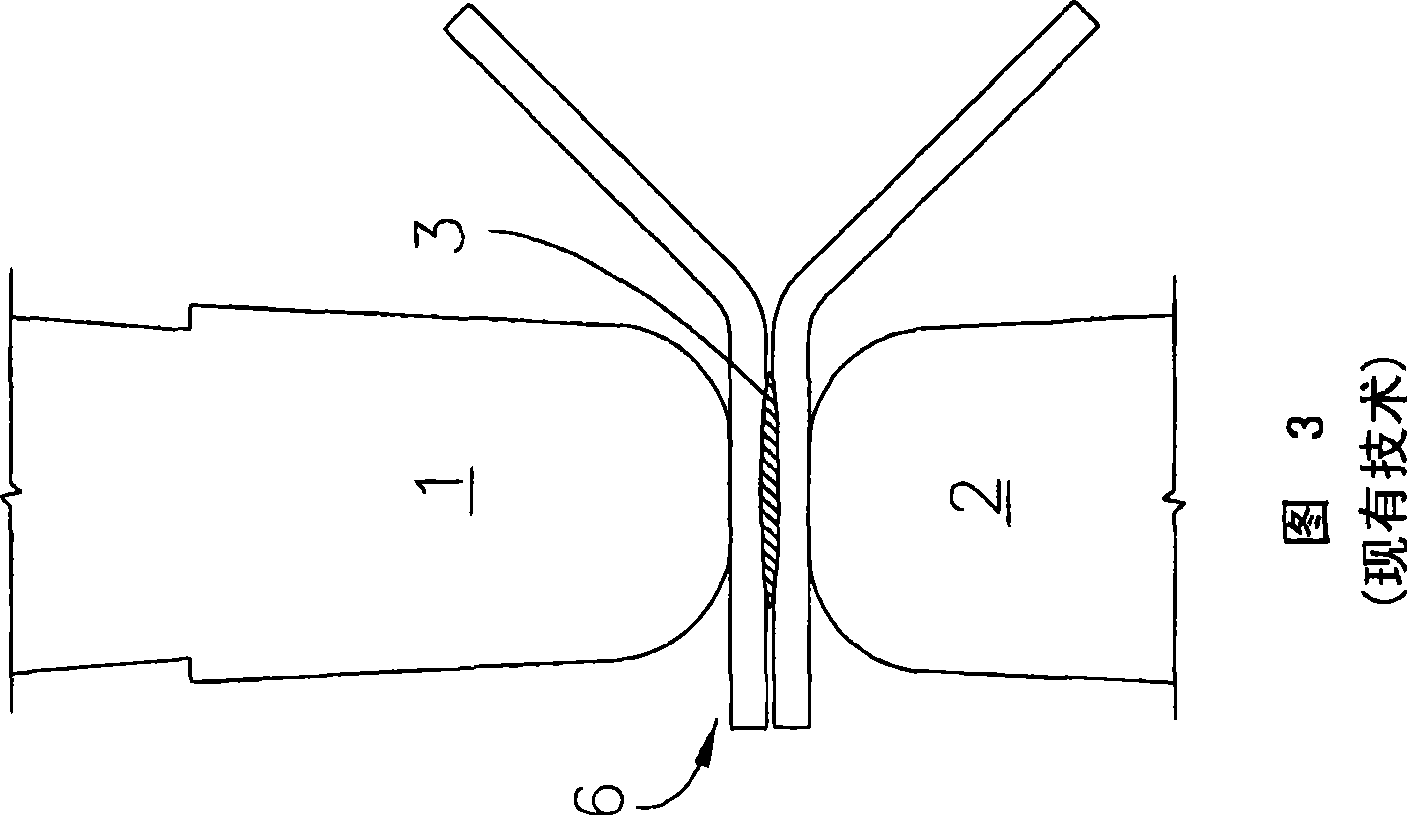

[0034] The present invention relates to a resistance welding system 10 (FIG. 4) for welding multiple (i.e., two or more) adjacent workpieces, such as automotive sheet metal or engine mount parts, to produce spot or seam welds 12 ( Figure 5 and Figure 8). Multiple sets of two workpieces 14, 16 having the same thickness are shown in the various embodiments described and illustrated herein; however, the system 10 may be used to weld a greater number of structural components having variable thickness. The workpieces 14, 16 may be formed from a wide range of rigid solid conductive metals, including steel. exist Figure 5 to Figure 5 c and Figure 7 to Figure 1 In the application shown in 1, the sheet metal workpieces 14, 16 preferably have opposing major surfaces 14a and 16a that can be joined by a two-electrode resistance / protrusion welding device such as the device 18 shown in FIG. 4 .

[0035] A novel aspect of the present invention involves the treatment of one of the workp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com