Permanent magnet body with symmetric magnetic field intensity of right and left arc, manufacturing method and apparatus

A technology of magnetic field strength and permanent magnets, which is applied in the direction of inductance/transformer/magnet manufacturing, permanent magnets, electrical components, etc., can solve the problems of unbalanced operation of motors, noise and short life, high motor speed, etc., to reduce and improve the working current The effect of improving efficiency and working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

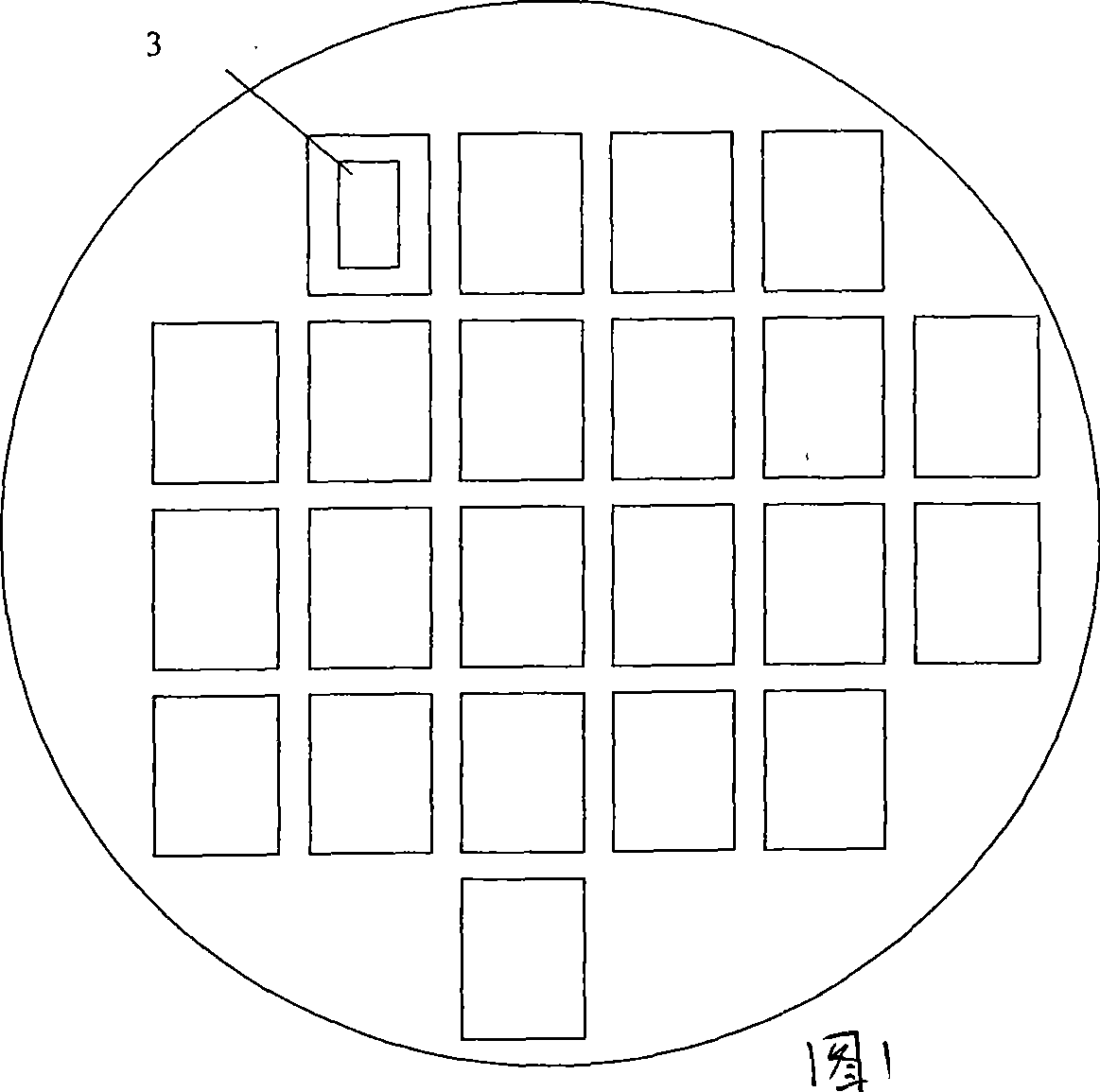

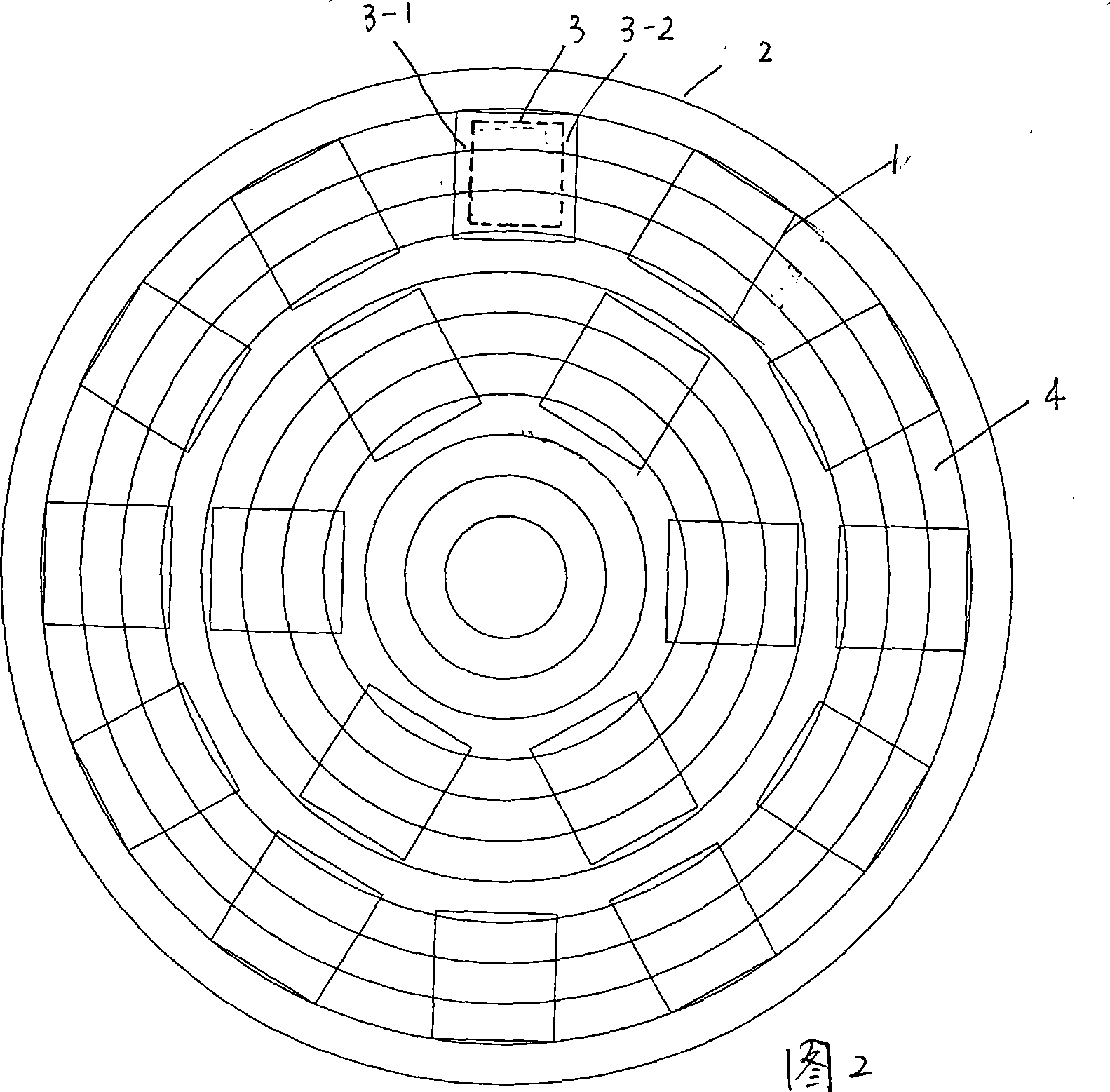

[0016] Ferrite permanent magnet and its preparation and equipment: The commonly used ferrite permanent magnet preparation process-wet pressing of permanent ferrite is adopted. Wet pressure magnetic field forming technology can fully orient the magnetic domains of magnetic materials, and the magnetic properties of the obtained magnets are higher. Therefore, wet pressure magnetic field forming technology has been widely used in the production of high-performance permanent magnet materials. The increase of orientation magnetic field strength during wet pressing helps to improve the magnetic parameters of anisotropic magnets. Wet pressure magnetic field molding is: first make the powder into a slurry with a particle size of 1 micron or less and a water content of about 20% to 40%; then add the slurry into the mold cavity by manual or automatic feeding; from During the period from the start of feeding to the end of molding, a sufficiently strong magnetic field strength is maintaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com