Integration combustion pressure sensor for internal combustion engine

A combustion pressure and internal combustion engine technology, applied in the direction of combustion ignition, combustion methods, instruments, etc., can solve the problem that the system is susceptible to interference from external vibration and temperature changes, etc., to improve system reliability, reduce fuel consumption and pollution, and reduce external noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

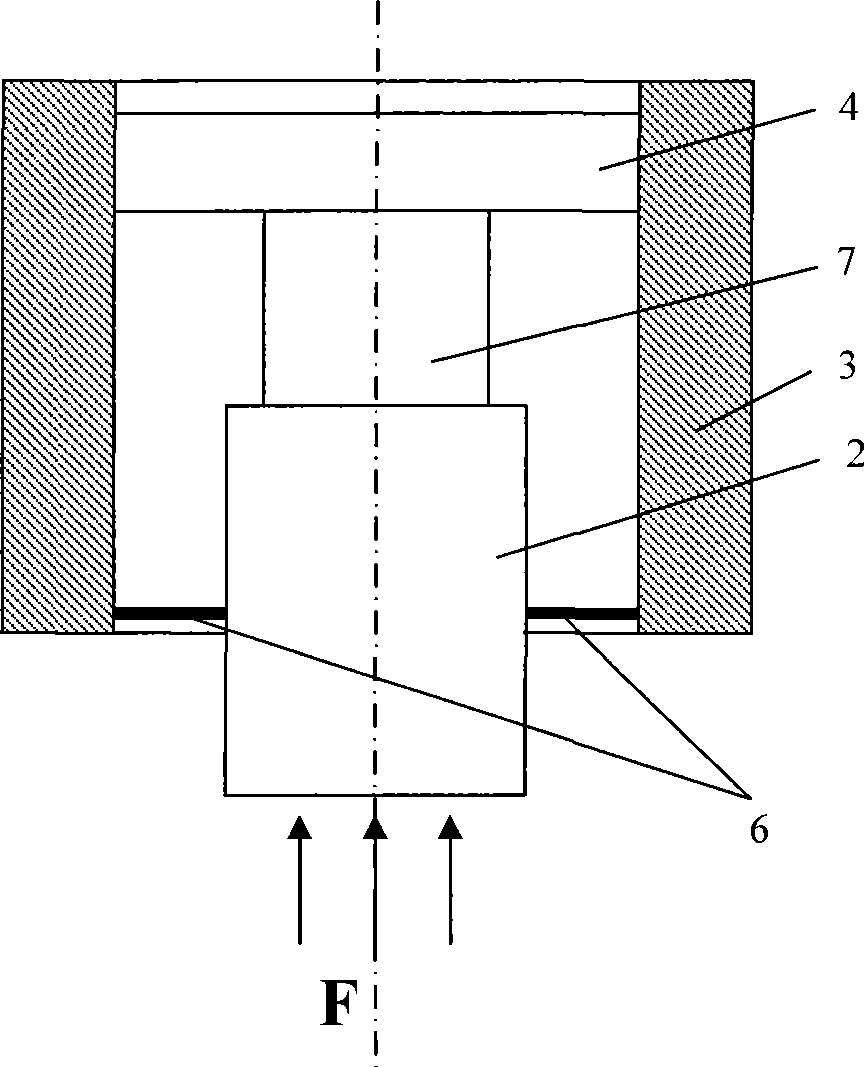

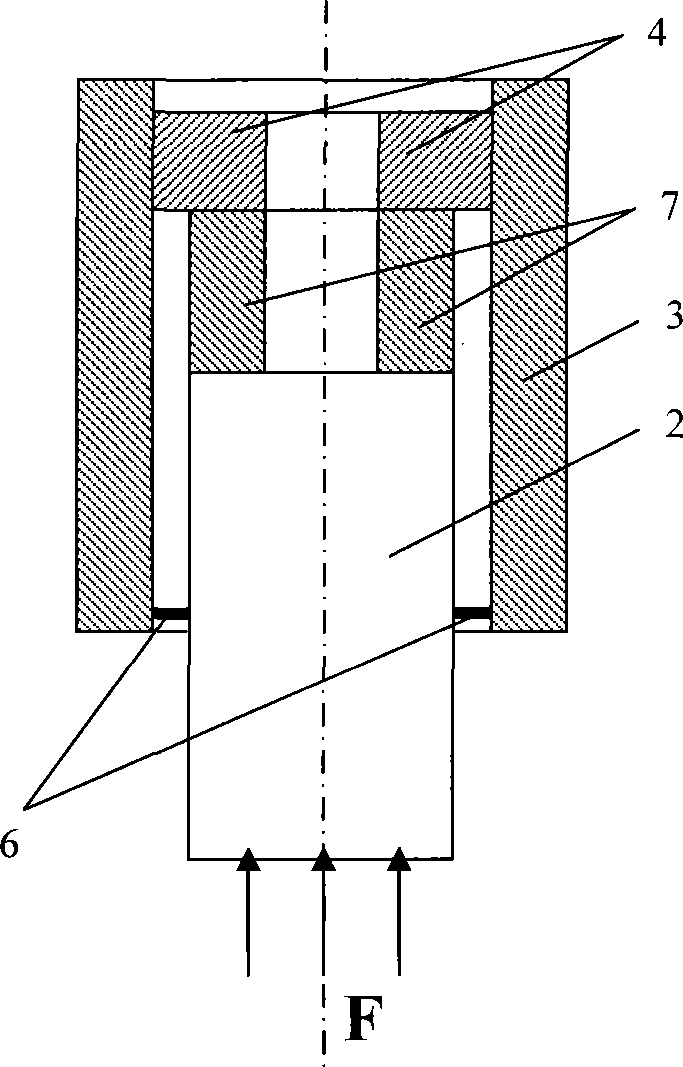

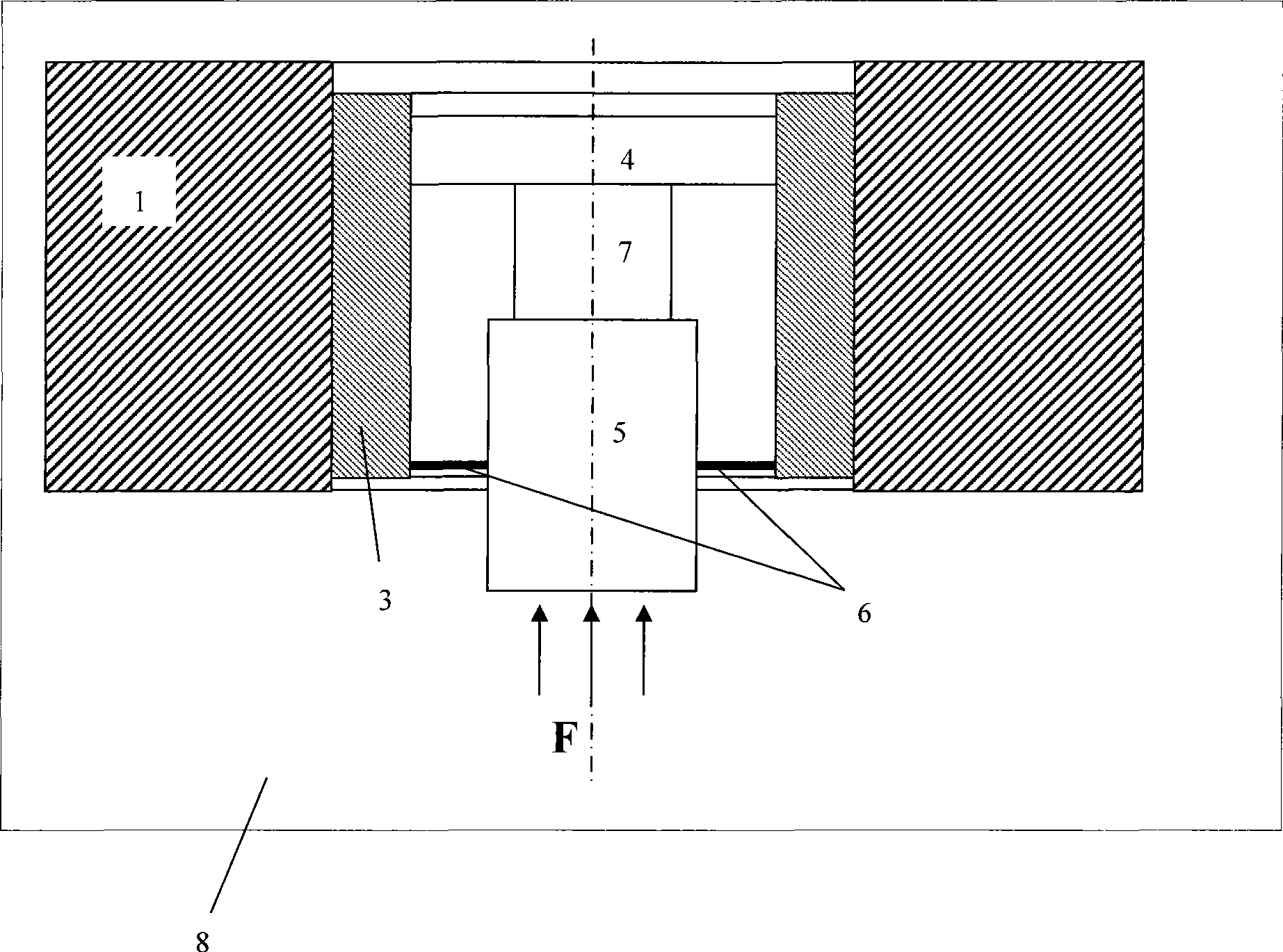

[0047] Such as Figure 1-Figure 2 As shown, the components of the integrated combustion pressure sensor of the present invention include a piezoelectric (force measuring) element 7, a rigid connection element 4, a flexible connection element 6, a housing 3, an internal combustion engine functional element 2 and other accessories such as signal transmission, signal processing, power lines, etc. One end of the piezoelectric element 7 is connected to the rigid connection element 4 by sintering or brazing or bonding, and the other end is connected to the functional element 2 of the internal combustion engine, such as a glow plug or spark plug, and the rigid connection element 4 is connected by sintering or brazing or bonding on the rigid shell 3. The functional element 2 of the internal combustion engine is connected to the shell directly or through the accessories of the functional element, such as the housing of the functional element, or other parts of the functional element t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com