Control method of acetaldehyde content during acetic acid synthesis from methanol carbonylation

A control method and chemical synthesis technology, which can be applied to the preparation of carboxylic acid by carbon monoxide reaction, organic chemistry and other directions, can solve the problems of polypropionic acid by-products and other problems, and achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

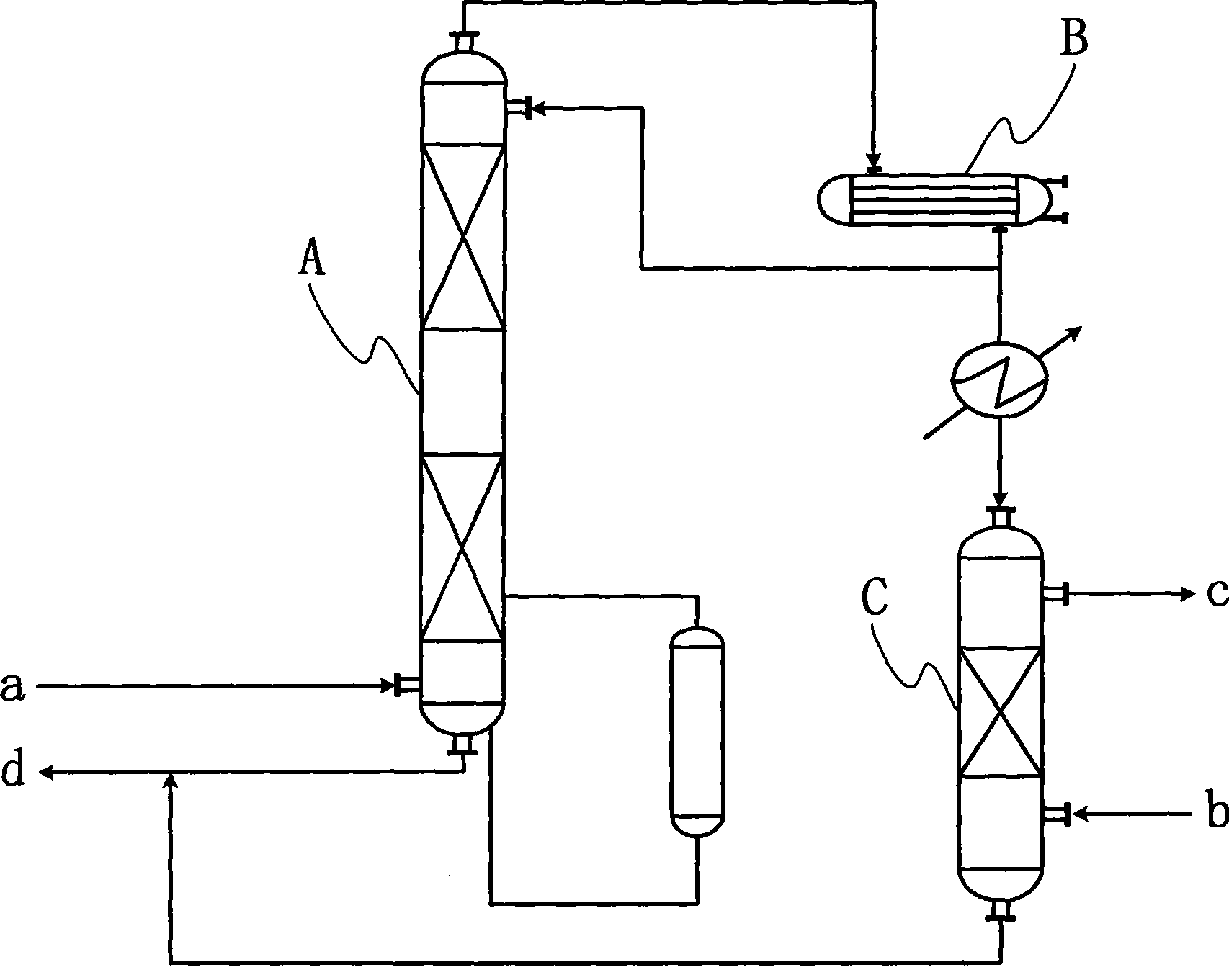

Method used

Image

Examples

Embodiment 1

[0027] The composition of the "light components" of the distillation sent to the distillation tower is:

[0028] Component Methanol Methyl iodide Methyl acetate Acetaldehyde acetic acid water content% 1~5 2~8 1~6 0.5~3 30~60 40~70

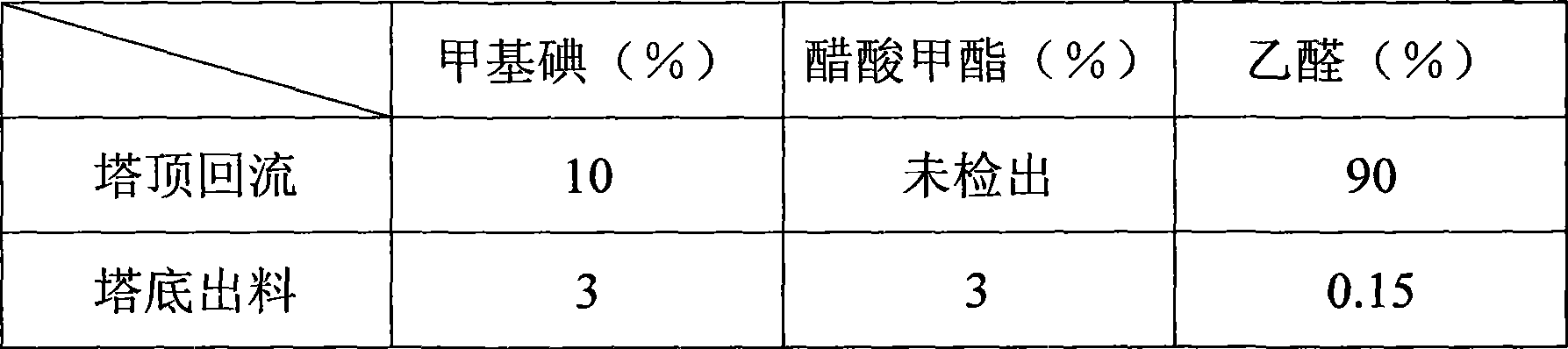

[0029] The distillation tower is 40 meters high, the tower diameter is 1 meter, the inside of the tower is stainless steel corrugated structured packing, the light component feed flow is 60L / h, the bottom temperature is 100℃, the top temperature is 30℃, the top pressure is 100KPa, reflux The ratio is 1:1. The material separation situation is as follows:

[0030]

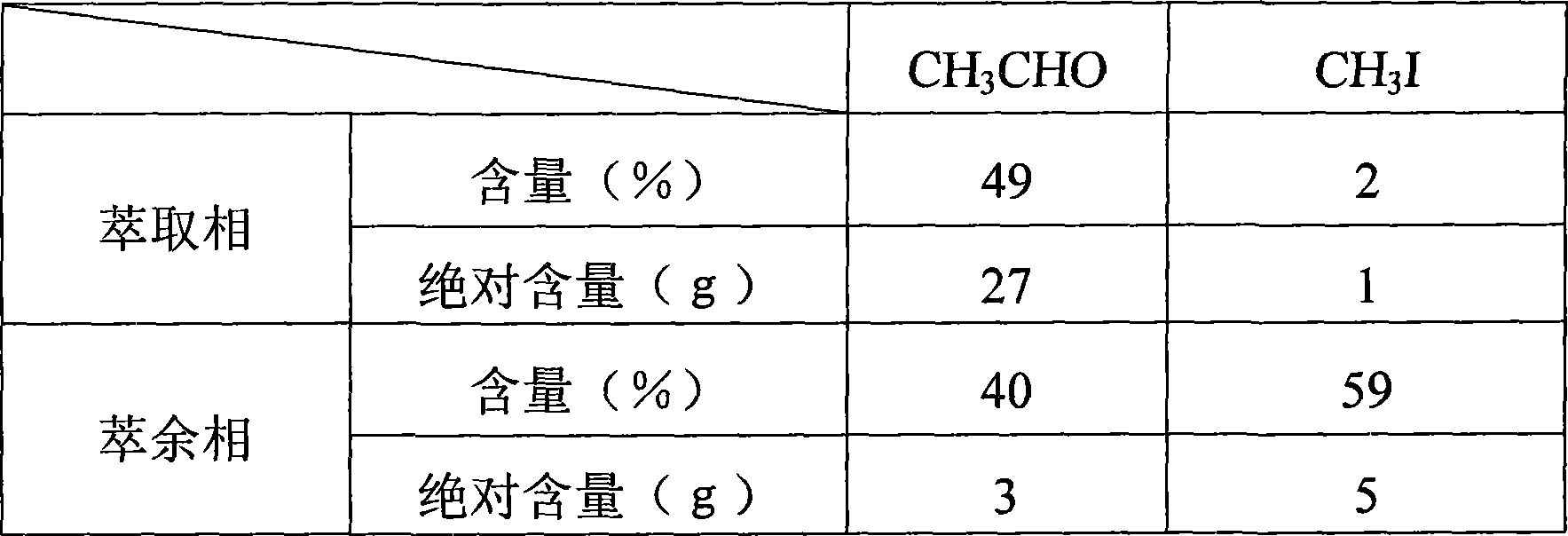

[0031] Cool the temperature of the material to 5°C, add cooling water to the material in a ratio of 1:1, control the pressure of the extraction tower to 150KPa, and the composition of the material after extraction and separation is as follows:

[0032]

Embodiment 2

[0034] The composition of the "light components" for distillation sent to the distillation tower is:

[0035] Component Methanol Methyl iodide Methyl acetate Acetaldehyde acetic acid water content% 1~5 2~8 1~6 0.5~3 30~60 40~70

[0036] The distillation tower is 40 meters high, with a diameter of 1 meter. The inside of the tower is stainless steel corrugated structured packing. The light component feed flow rate is 30L / h. The tower bottom temperature is 95℃, the top temperature is 25℃, the top pressure is 50KPa, and the reflux ratio 3:1. The material separation is as follows:

[0037]

[0038] Cool the temperature of the material to 0°C, add cooling water to the material in a ratio of 1:1, and control the pressure of the extraction tower to 300KPa after extraction and separation. The material composition is as follows:

[0039]

[0040] The comparison of the above results shows that the technical scheme of the present invention can eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com