Method for synthesizing methane by using coke-oven gas

A technology for synthesizing methane and coke oven gas, which is applied in the direction of climate sustainability, sustainable manufacturing/processing, and hydrocarbon production from carbon oxides, etc., to achieve the effects of high calorific value, energy saving, and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

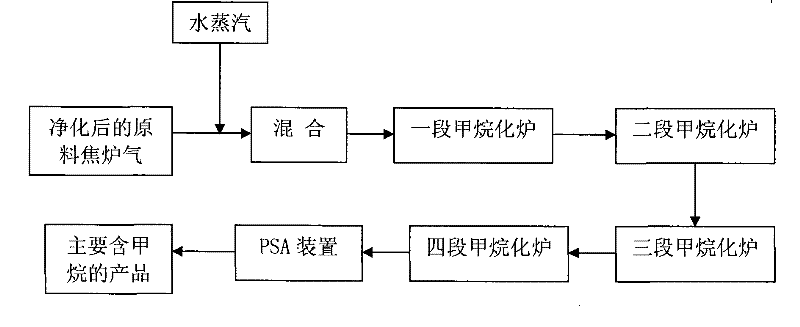

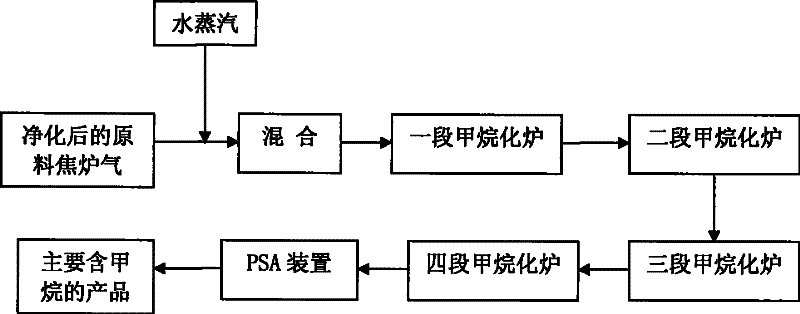

Image

Examples

Embodiment 1

[0040] The method for utilizing coke oven gas to synthesize methane in this embodiment comprises the following main steps:

[0041] (1), Purification and removal of impurities: First, the coke oven gas is removed from impurities such as benzene, naphthalene, heavy hydrocarbon compounds, sulfides, etc. through the purification system, and then the coke oven gas composition (Vol%) is: H 2 58. CH 4 26.5,N 2 4. O 2 0.5, CO 7, CO 2 2. CmHn 2;

[0042] (2), compression heat exchange and adding water vapor: Compress the coke oven gas purified in the above step (1) to about 0.5Mpa at normal pressure, and exchange heat to about 350°C; then add water vapor, the amount of water vapor added CH in coke oven gas according to raw materials 4 Calculated so that H 2 O and CH 4 The molar ratio is 0.2:1;

[0043] (3), one-stage methanation reaction: after the purified coke oven gas is mixed with water vapor, it enters the first-stage methanation reaction furnace, and under the actio...

Embodiment 2

[0048] The method for utilizing coke oven gas to synthesize methane in this embodiment comprises the following main steps:

[0049] (1), Purification and removal of impurities: First, the coke oven gas is removed from impurities such as benzene, naphthalene, heavy hydrocarbon compounds, sulfides, etc. through the purification system, and then the coke oven gas composition (Vol%) is: H 2 58. CH 4 26.5,N 2 4. O 2 0.5, CO 7, CO 2 2. CmHn 2;

[0050] (2), compression heat exchange and adding water vapor: Compress the coke oven gas purified in the above step (1) to about 1.2Mpa at normal pressure, and exchange heat to about 330°C; then add water vapor, the amount of water vapor added CH in coke oven gas according to raw materials 4 Calculated so that H 2 O and CH 4 The molar ratio is 0.7:1;

[0051] (3), one-stage methanation reaction: after the purified coke oven gas is mixed with water vapor, it enters the first-stage methanation reaction furnace, and under the actio...

Embodiment 3

[0056] The method for utilizing coke oven gas to synthesize methane in this embodiment comprises the following main steps:

[0057] (1), Purification and removal of impurities: First, the coke oven gas is removed from impurities such as benzene, naphthalene, heavy hydrocarbon compounds, sulfides, etc. through the purification system, and then the coke oven gas composition (Vol%) is: H 2 58. CH 4 26.5,N 2 4. O 2 0.5, CO 7, CO 2 2. CmHn 2;

[0058] (2) Compression heat exchange and adding water vapor: compress the coke oven gas purified in the above step (1) to about 2Mpa, and exchange heat to about 400°C; CH in furnace gas 4 Calculated so that H 2 O and CH 4 The molar ratio is 1.0:1;

[0059] (3), one-stage methanation reaction: after the purified coke oven gas is mixed with water vapor, it enters the first-stage methanation reaction furnace, and under the action of a nickel catalyst, a first-stage methanation reaction is carried out; after the first-stage reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com