Design method of fluid curtain bed gas-liquid contact reaction device

A reaction device and gas-liquid contact technology, which are applied in chemical methods, separation methods, chemical instruments and methods for reacting liquid and gas medium, etc., can solve problems such as complex design methods, and achieve easy implementation and high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

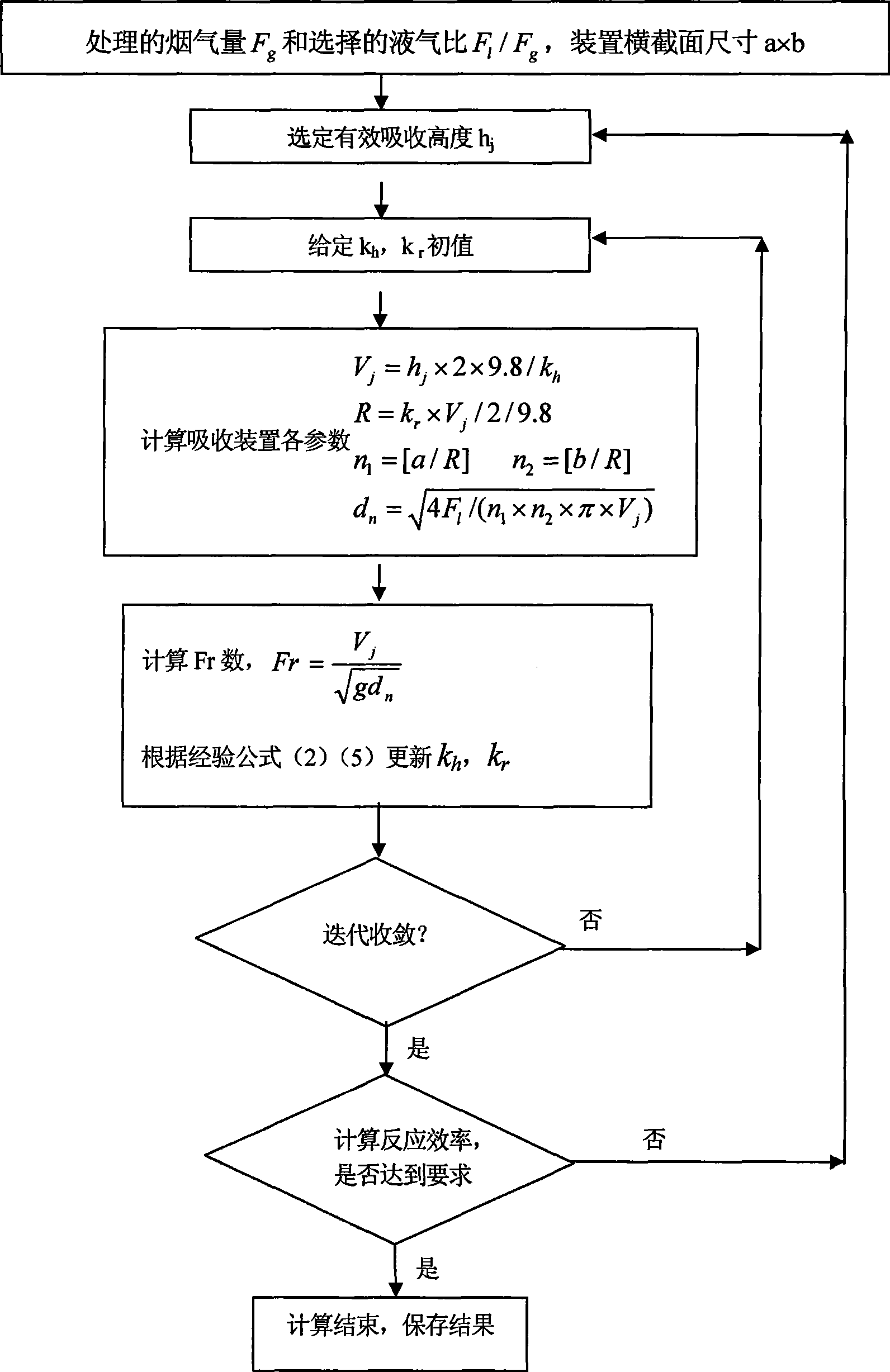

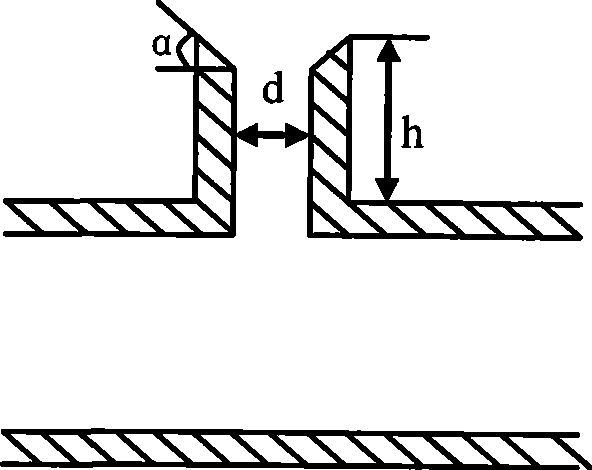

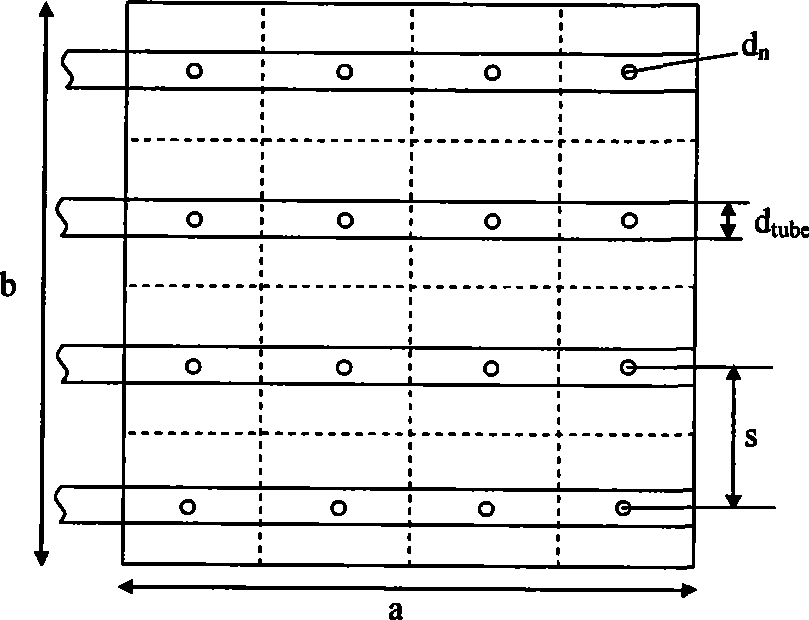

[0015] see figure 1 , when designing the gas-liquid reaction device, the known quantity is: the liquid-gas ratio of the device (F l / F g ), the amount of flue gas to be treated (F g ) and imported flue gas SO 2 Concentration C in , the scale of the reaction device (cross-sectional size a×b), the parameter to be solved is the arrangement method of the liquid phase injection device, including the number of nozzles (n 1 ×n 2 ), nozzle diameter d n , and the nozzle spacing s, the diameter of the spraying main pipe d tube , and the effective absorption height h when the required reaction efficiency is reached j . The calculation method is based on the following principles:

[0016] 1. Increase the injection velocity V of the liquid in the nozzle j , can increase the height of the sprayed liquid column, increase the gas-liquid contact area; increase the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com