Double egg-albumen fermentation type frozen milk food and preparation method thereof

A fermented, double-protein technology, applied in the fields of dairy products and jelly food, can solve the problems of difficult taste and posture, reduced gelling ability, and high requirements for packaging forms, and achieves optimization of processing technology, balanced protein nutrition, and formula design. optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

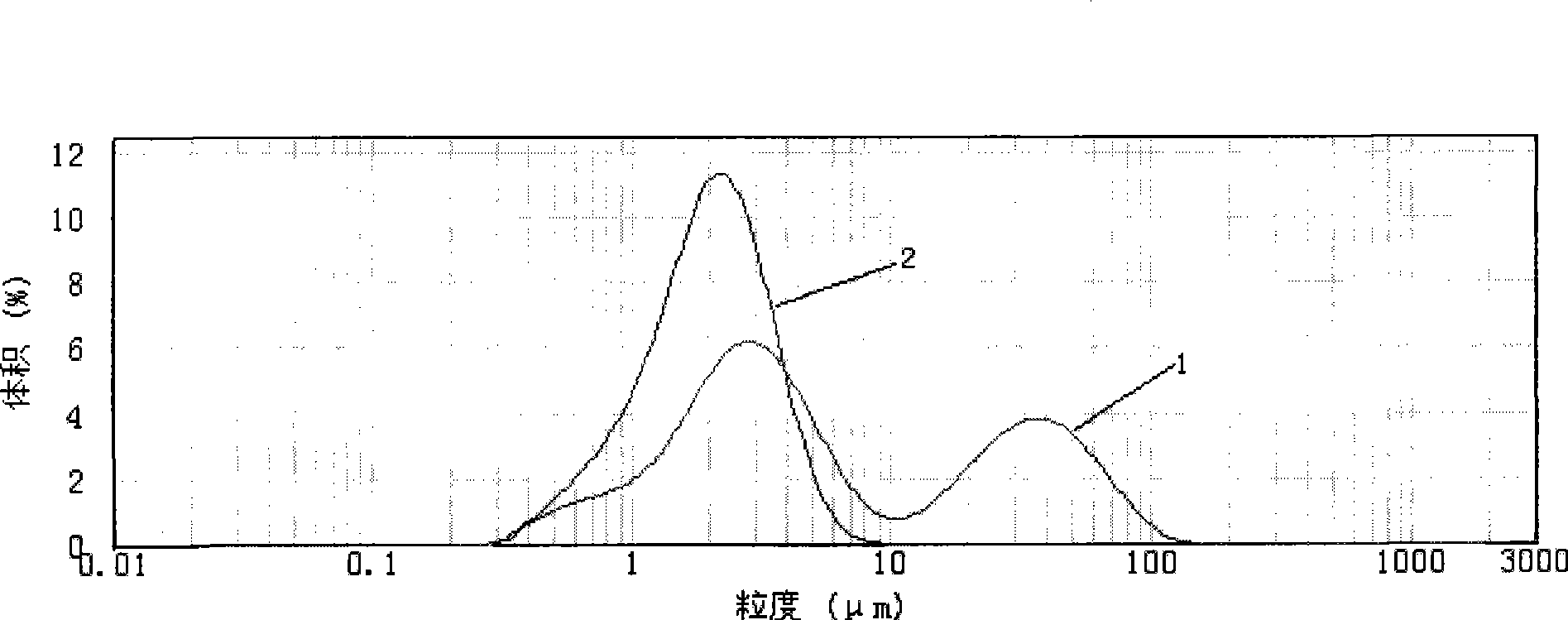

Image

Examples

Embodiment 1

[0036] Double-protein fermented milk jelly composition of the present invention is as follows by weight: 33.4 parts by weight of fermented base liquid, 10.0 parts by weight of sweetener sucrose, 1.0 parts by weight of thickener (wherein 0.08 parts by weight of xanthan gum, 0.17 parts by weight of gelatin parts, 0.10 parts by weight of sodium carboxymethyl cellulose, 0.45 parts by weight of konjac mannan, 0.20 parts by weight of carrageenan), 0.70 parts by weight of acidity regulator (wherein KCl 0.08 parts by weight, Na 2 HPO 4 0.10 parts by weight, 0.20 parts by weight of trisodium citrate, 0.32 parts by weight of citric acid), 0.03 parts by weight of preservative potassium sorbate, 0.03 parts by weight of food essence, and supplemented with water to 100 parts by weight.

[0037] The preparation method of double-protein fermented milk jelly food of the present invention comprises the steps:

[0038] (1) Add soybean protein and water and stir and mix to obtain a solution in f...

Embodiment 2

[0043] Double-protein fermented milk jelly ingredients are as follows in parts by weight: 33.4 parts by weight of fermented base liquid, 10.0 parts by weight of sweetener sucrose, 1.1 parts by weight of thickener (wherein 0.08 parts by weight of xanthan gum, 0.15 parts by weight of gelatin, carboxylate 0.2 parts by weight of sodium methylcellulose, 0.42 parts by weight of konjac mannan, 0.25 parts by weight of carrageenan), 0.60 parts by weight of acidity regulator (wherein KCl 0.06 parts by weight, Na 2 HPO 4 0.06 parts by weight, 0.20 parts by weight of trisodium citrate, 0.28 parts by weight of citric acid), 0.03 parts by weight of preservative potassium sorbate, 0.03 parts by weight of food essence, and supplemented with water to 100 parts by weight.

[0044] The preparation method of double-protein fermented milk jelly food of the present invention comprises the steps:

[0045] (1) Add soybean protein and water in fresh milk and stir and mix to obtain a solution, so tha...

Embodiment 3

[0050] The ingredients of the double-protein fermented milk jelly are as follows in parts by weight: 33.4 parts by weight of fermented base liquid, 6.0 parts by weight of sweetener sucrose and 0.0001 parts by weight of acesulfame potassium, 1.5 parts by weight of thickener (wherein 0.1 part by weight of xanthan gum , 0.20 parts by weight of gelatin, 0.50 parts by weight of sodium carboxymethylcellulose, 0.45 parts by weight of konjac mannan, 0.25 parts by weight of carrageenan), 0.6 parts by weight of acidity regulator (wherein KCl 0.06 parts by weight, Na 2 HPO 4 0.09 parts by weight, 0.20 parts by weight of trisodium citrate, 0.25 parts by weight of citric acid), 0.03 parts by weight of preservative potassium sorbate, 0.02 parts by weight of food essence, and supplemented with water to 100 parts by weight.

[0051] The preparation method of double-protein fermented milk jelly food of the present invention comprises the steps:

[0052] (1) Add soybean protein and water in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com