Large power carbon fiber electric heating tube for industrial use

A high-power, carbon fiber technology, applied in the field of electric heating tubes, can solve the problems that it is difficult to make durable and thermally efficient electric heating tubes, affect the use range of electric heating tubes, and have short mission life. wide temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

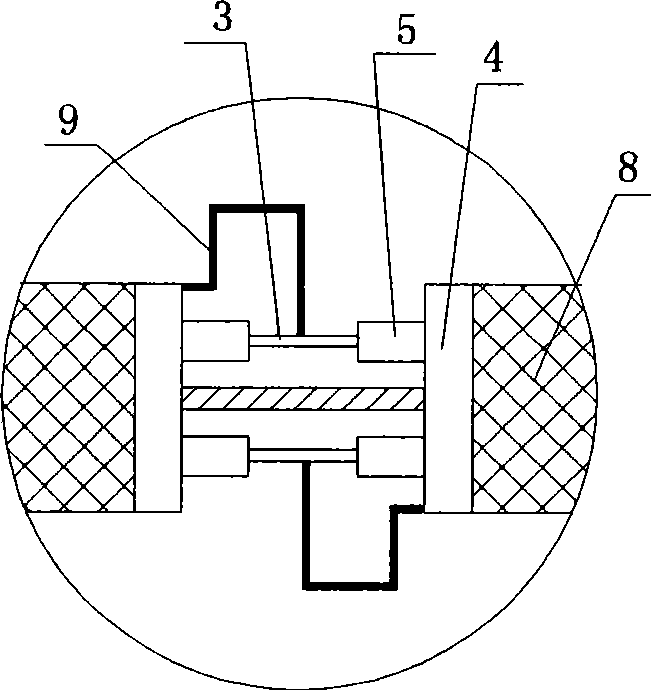

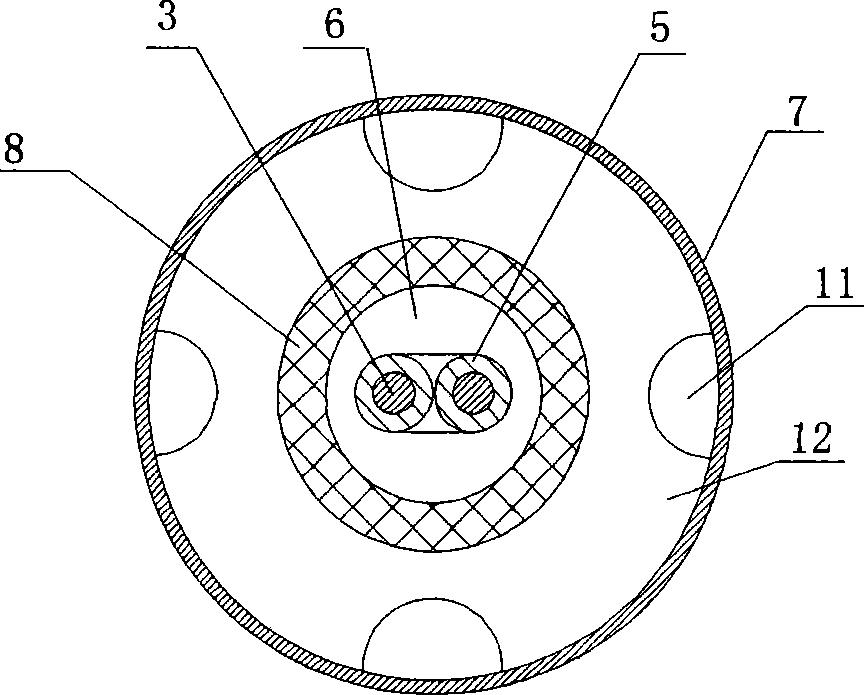

[0017] The industrial high-power carbon fiber electric heating tube of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] As shown in Figures 1 and 2, the electric heating tube is composed of an outer electrode 1, an electrode head 2, an electrode wire 3, an inner support 6, a tube shell 7, an electric heating body 8, and an exhaust hole 10, of which more than two electric heating The body 8 is connected in series in the tube shell 7, an inner bracket is arranged between the electric heating body 8 and the tube shell 7, an inner casing 5 runs through the middle of the electric heating body 8, and an electrode wire 3 is passed through the inner casing 5, and the inner casing 5 and the electric heating body 8 are provided with an inner bracket 6, and the two ends of the electric heating body 8 are provided with a sleeve electrode 4, and the sleeve electrode 4 is connected to the electrode line 9 through a connecting wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com