Method for making individuation sheet material model

A production method and board technology, applied in the field of personalized design and production, can solve the problems of monotonous color, single structure, and loss of freshness of design patterns, and achieve the effect of rich content and positive economic significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

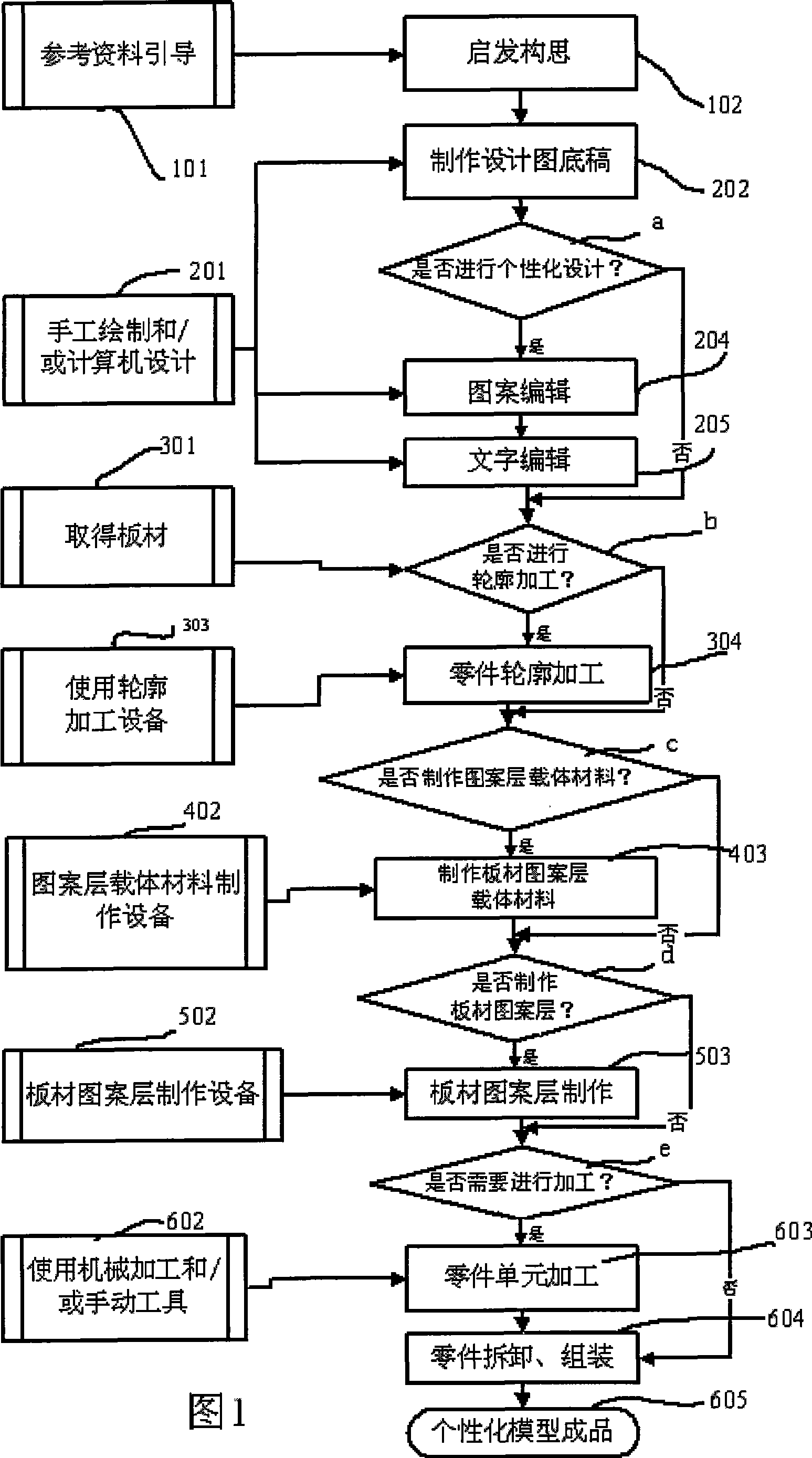

[0047] After obtaining the sheet material step 301, enter whether to perform contour processing judgment step b; if it is determined to perform contour processing, then enter the use of contour processing tools in step 303 to perform part contour processing 304; if not perform contour processing, then enter whether to make a plate Step c of judging the material of the pattern layer.

[0048] If it is confirmed that the board pattern layer material is to be made, then use the pattern layer carrier material manufacturing equipment in step 402 to make the board pattern layer carrier material 403, otherwise, directly enter the step of judging whether to proceed with the board pattern layer.

[0049] If it is confirmed to make the plate pattern layer, then use the plate pattern layer production equipment shown in step 502, such as printer, printing machine, inkjet printer, to carry out the making of the plate pattern layer shown in 503; otherwise, directly enter whether the next ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com