Rapid dust removal method and device in tunnel

A dust suppression device and technology for dust suppression, applied in the directions of safety devices, dust prevention, earthwork drilling, etc., can solve problems such as difficult drilling, insignificant effect, and buried drilling accidents, so as to reduce accidents, achieve good slag discharge effect, and avoid The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

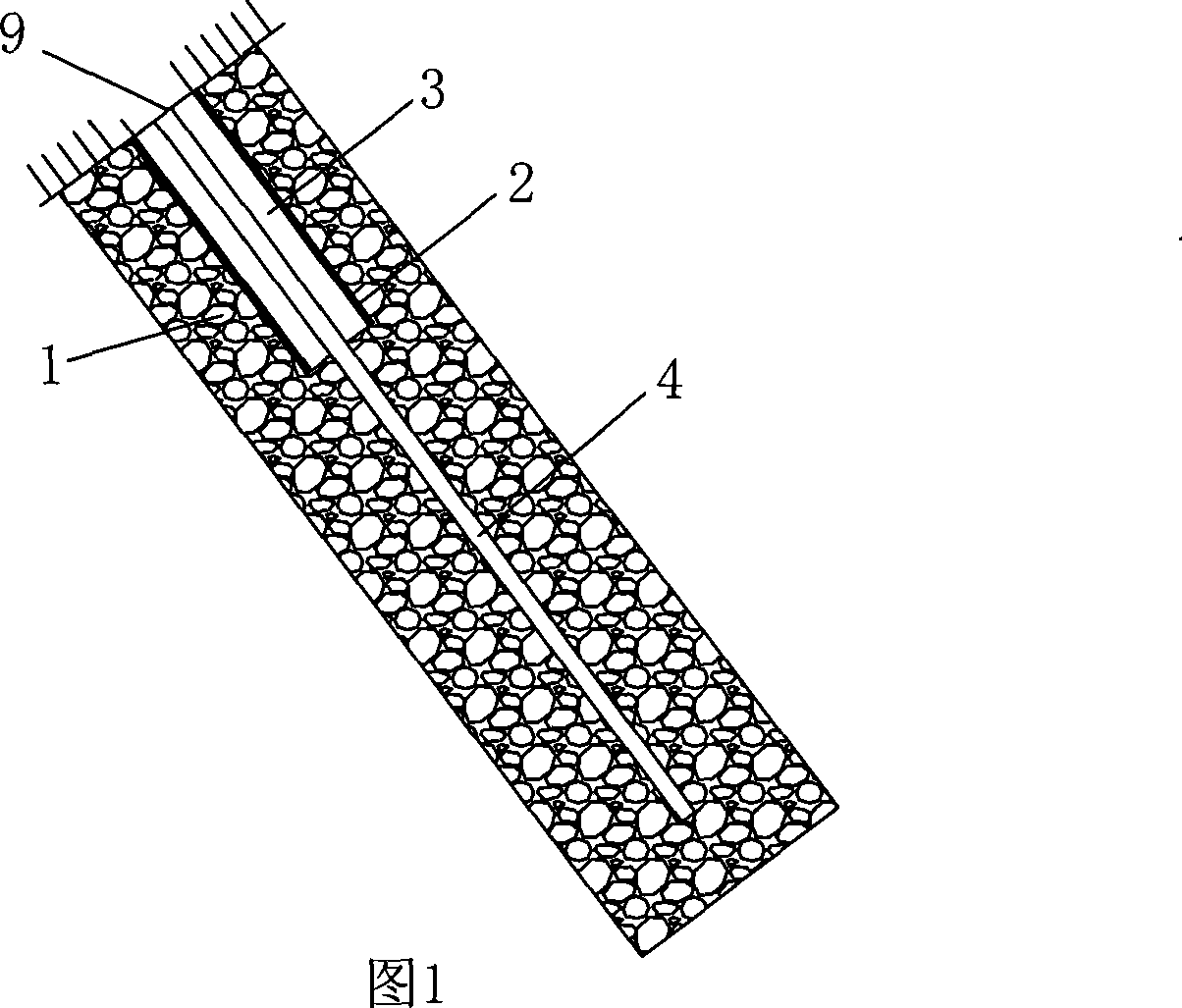

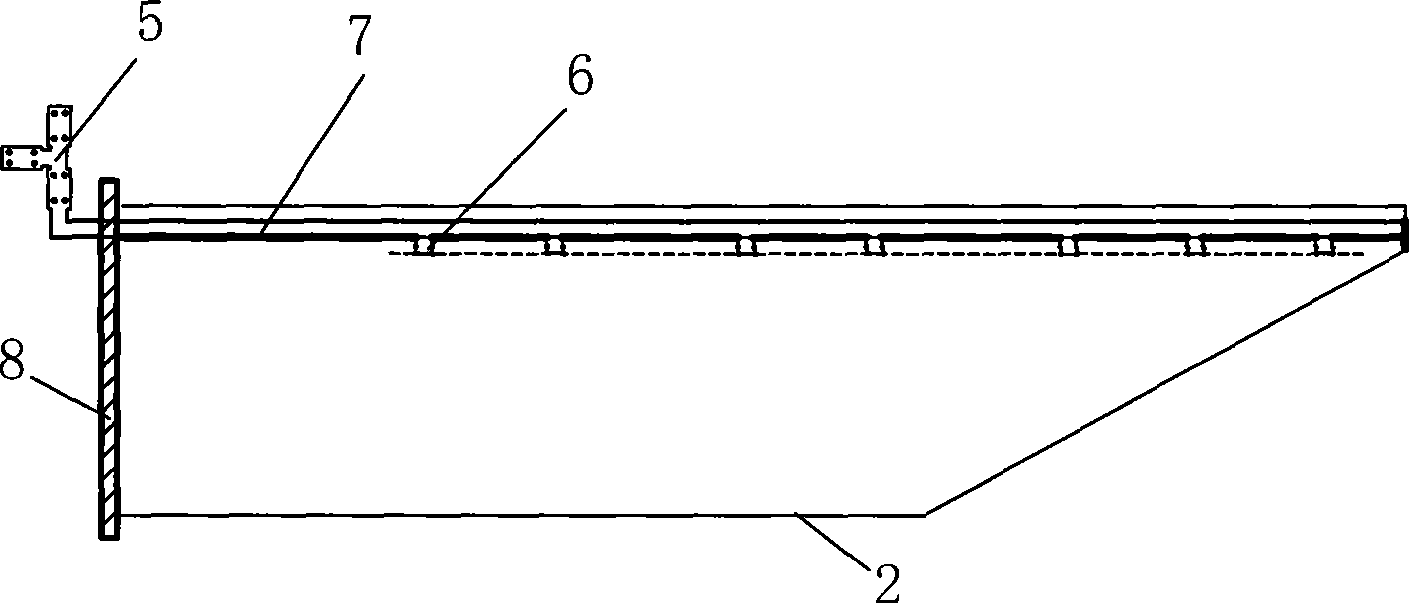

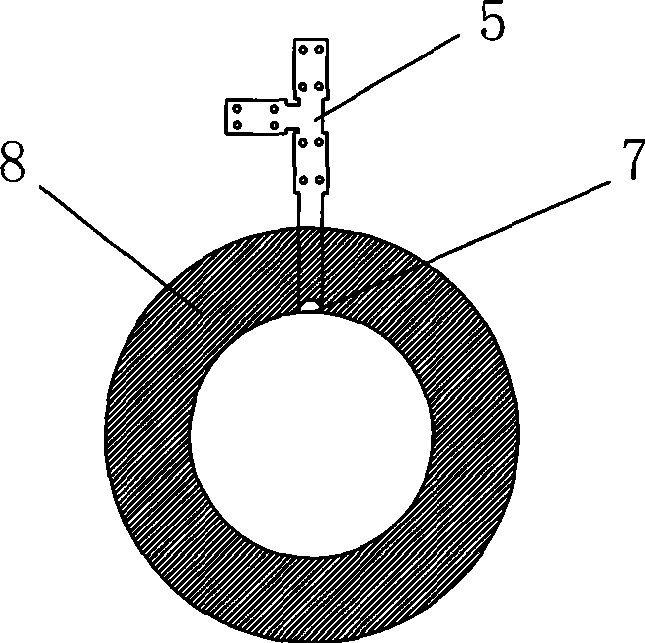

[0024] Referring to Fig. 1, in the inside of the front end hole 9 of the borehole, the annular area between the drill pipe and the rock wall of the front end hole is the dust fall area 3, and the spray head 6 is arranged in the dust fall area 3, and the spray head 6 is communicated with along the drill The auxiliary pipe 7 arranged in the axial direction of the hole 4, the outer port of the auxiliary pipe 7 is led out of the borehole 4, and is provided with a high-pressure tee joint 5, and the compressed air and water are respectively connected to the auxiliary pipe 7 through the tee joint 5 .

[0025] In specific implementation, the rock wall sheath pipe 2 is set in the front end hole 9 of the borehole, the dust reduction area 3 is formed between the rock wall sheath pipe 2 and the drill pipe, and the auxiliary pipe 7 is fixedly arranged on the inner side of the rock wall sheath pipe 2 On the wall, a flange 8 is connected to the outer port of the rock wall sheathing pipe 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com