Machine for dust removal by filtration of water curtain

A filter dust removal, water curtain technology, applied in the direction of dispersed particle separation, chemical instruments and methods, use of liquid separation agent, etc., can solve the problems of low dust removal rate, easy to block, large volume, etc., to improve the dust removal rate, avoid blockage, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

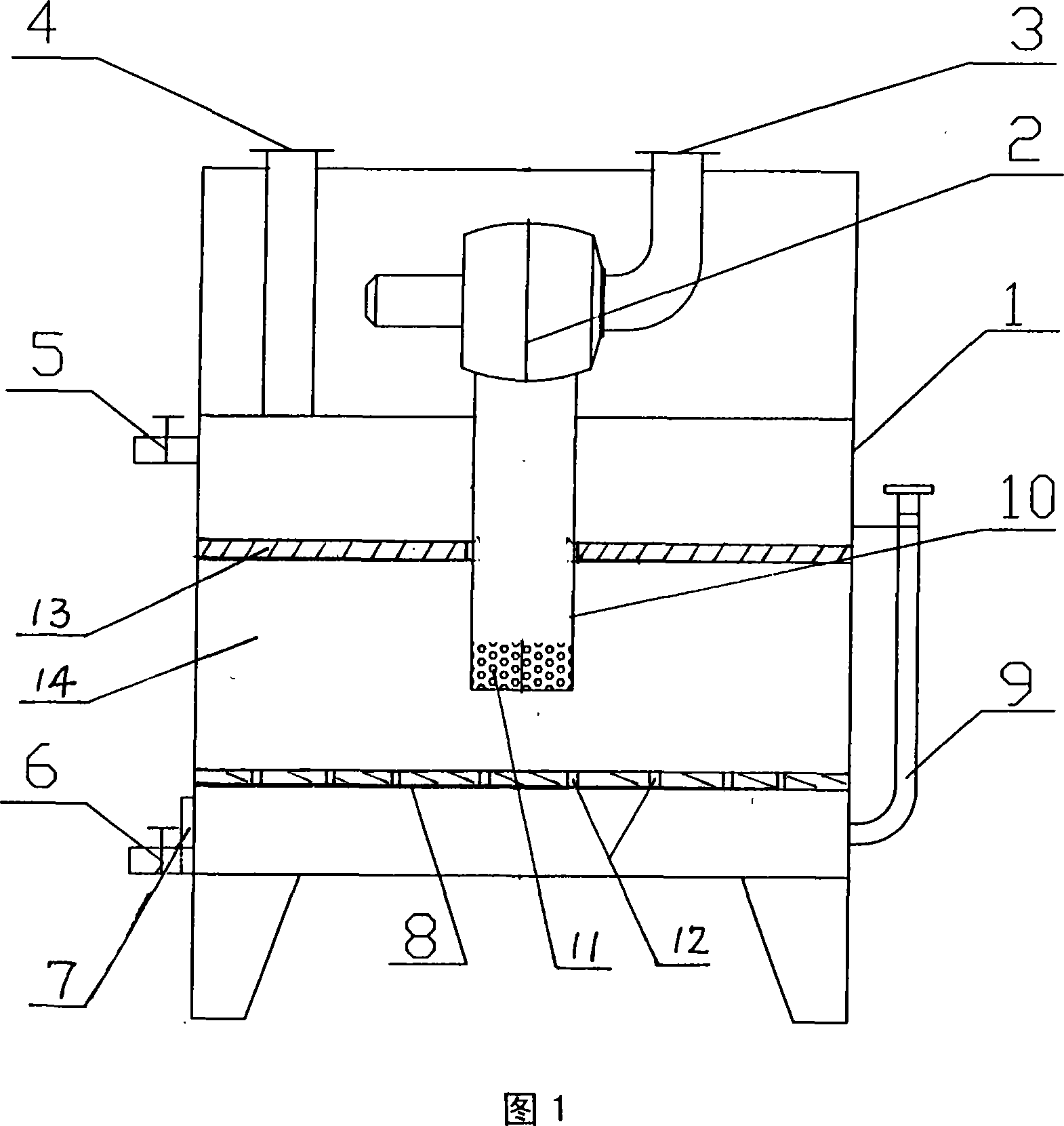

[0007] A water curtain filter and dedusting machine, comprising a housing 1, a fan 2, the housing 1 is provided with a water inlet valve 5, a drain valve 6, a dust removal port 7 and a water mark 9, and the housing 1 is a square cavity 14, The lower part of the cavity 14 is provided with a square water baffle 8, the water baffle 8 is provided with a through hole 12, the upper part of the cavity 14 is provided with a circular water baffle 13 with a through hole in the middle, and the ventilation pipe 10 of the fan 2 passes through the circular water baffle 13. The through hole on the shaped water retaining plate 13 is inserted in the cavity 14, and the side wall at one end of the ventilation pipe 11 has an air hole 11, and the exhaust pipe 4 is installed on the top of the housing 1 and communicates with the cavity 14. The air inlet pipe 3 of the blower fan 2 is connected with the dusty air source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com