Dust removal device for stone processing

A technology of dust removal device and stone processing, applied in the direction of using liquid separating agent, loose filter material filter, gravity filter, etc., can solve the problems of insufficient dust collection, low reliability of use, poor dust removal effect, etc. The amount of sewage produced, the reliability of use is improved, and the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

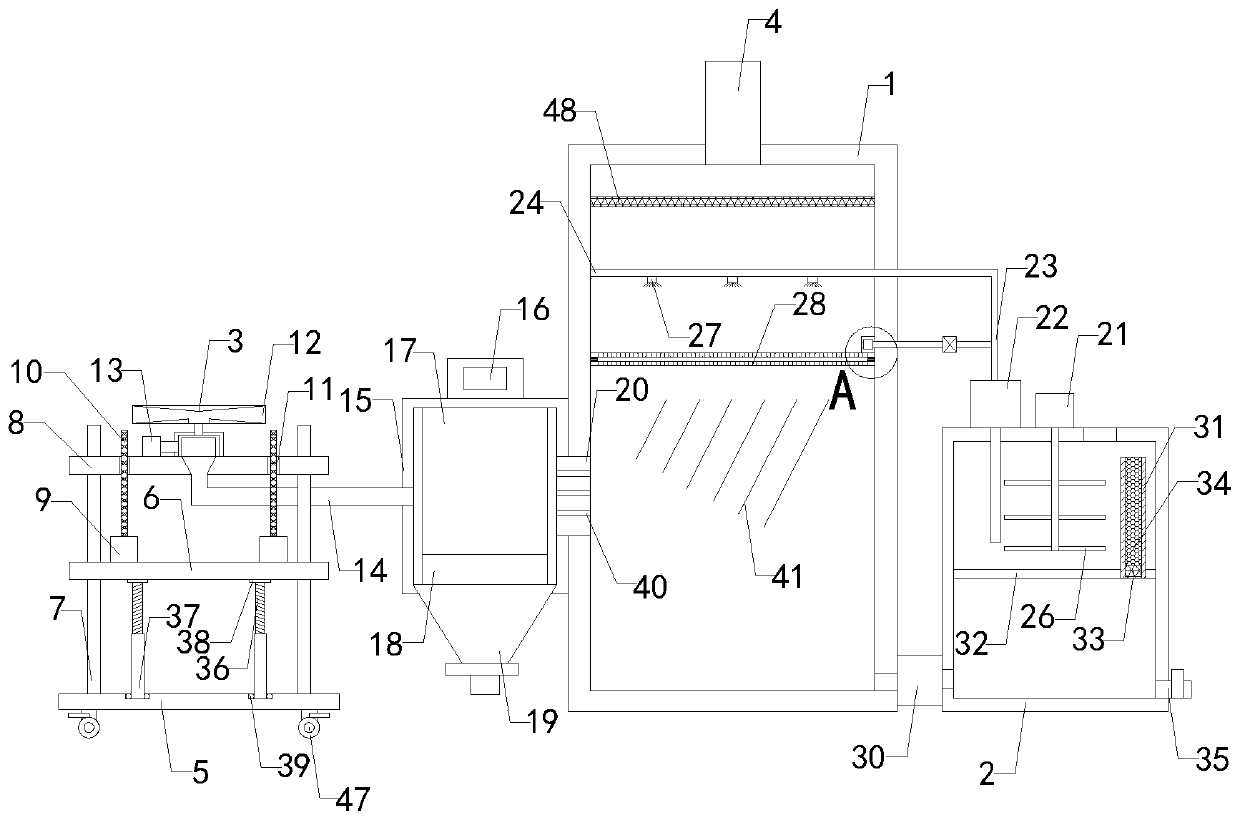

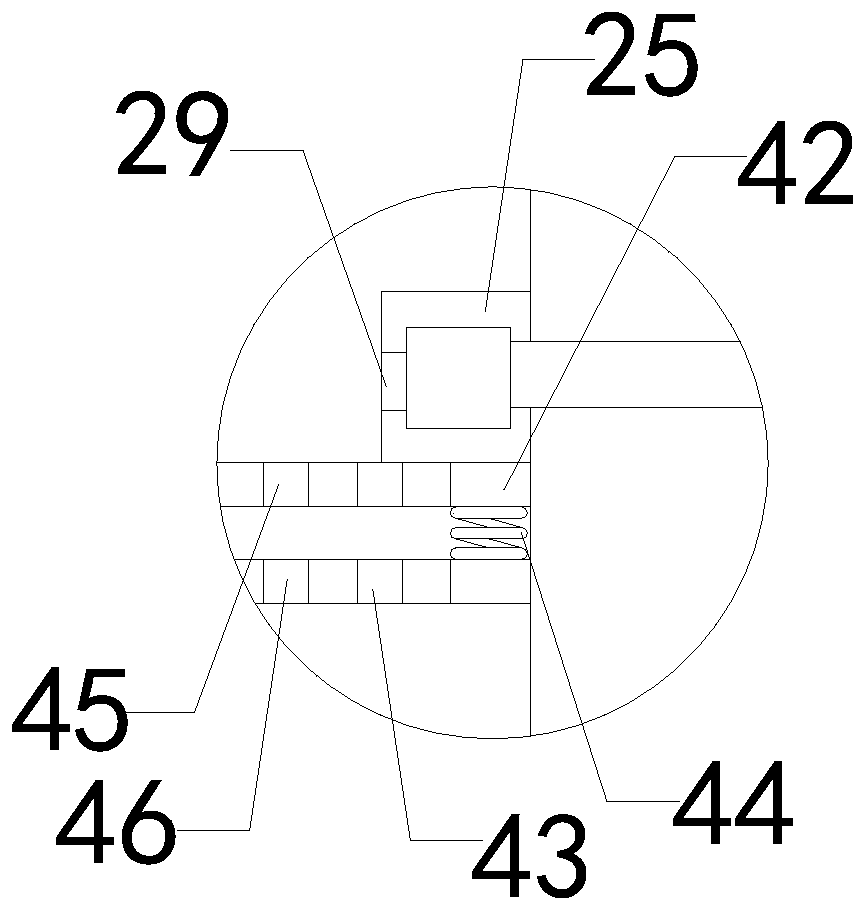

[0017] Such as Figure 1 to Figure 2As shown, a dust removal device for stone processing of the present invention includes a dust removal tower 1, a water tank 2 and a dust collection cover 3. The interior of the dust removal tower 1 is provided with a working chamber, and the top of the dust removal tower 1 is provided with an exhaust pipe 4 ; It also includes base 5, lifting plate 6, four groups of pillars 7, placing plate 8, two groups of first motors 9 and two groups of reciprocating lead screws 10, the four end points of lifting plate 6 are all provided with first through holes, placed The four end points of the plate 8 are provided with second through holes, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com