Concrete electrical pole and preparation thereof

A production method and concrete technology, applied in the direction of building types, buildings, towers, etc., can solve the problems of increased construction difficulty, waste of resources and production, and increase of bending strength, so as to reduce production and construction difficulty, improve bending strength, The effect of improving the bending moment resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

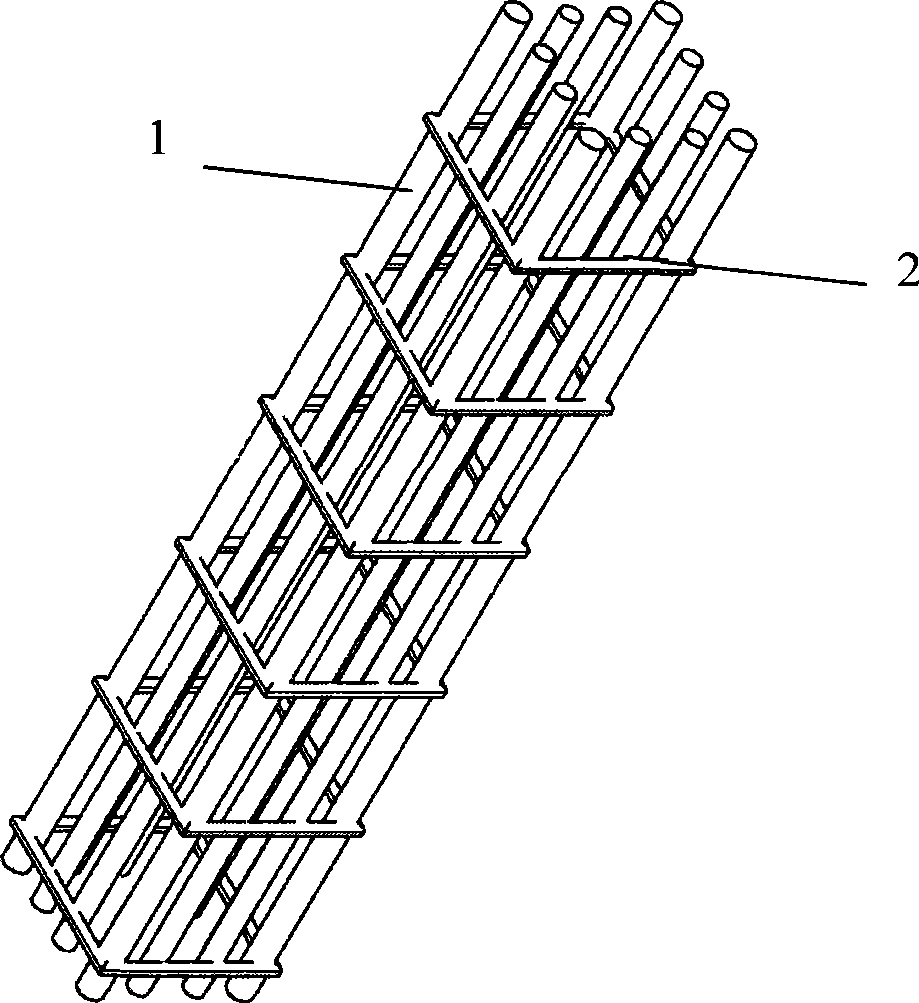

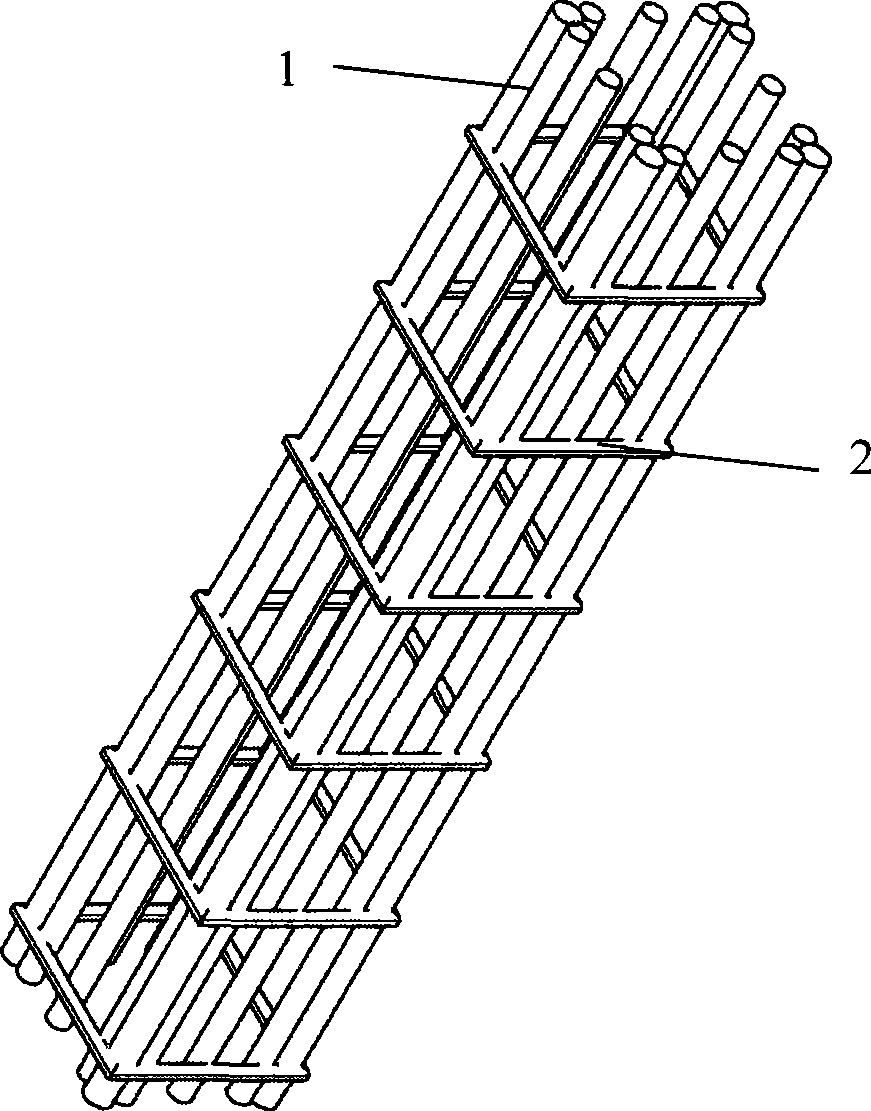

Image

Examples

specific Embodiment 2

[0030] attached Figure 5 It is a structural diagram of an embodiment in which a rectangular concrete pole of the present invention uses angle steel instead of four-corner rebar straight strips to add rebar straight strips to the inner surface of the right angle of the angle steel. In the figure, 1 is a straight strip of rebar, 2 is a rectangular frame, 3 is an angle steel, and 4 is concrete. As can be seen from the figure, the present embodiment adds 1 threaded steel (attached Figure 5 1), so that the bending strength of the concrete pole can be further improved.

specific Embodiment 3

[0031] attached Figure 6 It is a structural schematic diagram of an embodiment in which a rectangular concrete pole of the present invention adopts angle steel instead of four-corner rebar straight bar skeletons and adds triangular supports between the angle steels. (for clearly showing that the triangular support figure does not draw the rebar and the triangular support on the other two sides). Among the figure, 2 is a rectangular frame, 3 is an angle steel, and 5 is a triangular support. It can be seen from the figure that the triangular support is set between two angle steels. From the stability of the triangle, it can be seen that this structure has high stability and can effectively improve the bending strength of the concrete pole skeleton, thereby effectively improving the concrete pole. Bending strength.

[0032] attached Figure 7 It is a schematic side view of an embodiment of a rectangular concrete pole of the present invention that uses angle steel instead of f...

specific Embodiment 4

[0033] attached Figure 8 It is a top view structural diagram of an embodiment of a hexagonal skeleton formed by using angle steel instead of threaded steel straight strips to form a round concrete pole of the present invention. In the figure, 1 is a straight strip of rebar, 3 is an angle steel, 4 is concrete, and 5 is a triangular support. It can be seen from the figure that in this embodiment, six angle steels are used instead of six straight strips of rebar, and they are uniformly distributed. At this time, the angle between the two sides of the angle steel is 120°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com