Method and plant for drying and comminution of moist, mineral raw materials

A mineral raw material and drying technology, which is applied in clinker production, lighting and heating equipment, furnaces, etc., to achieve excellent combustion characteristics, reduce specific energy consumption, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

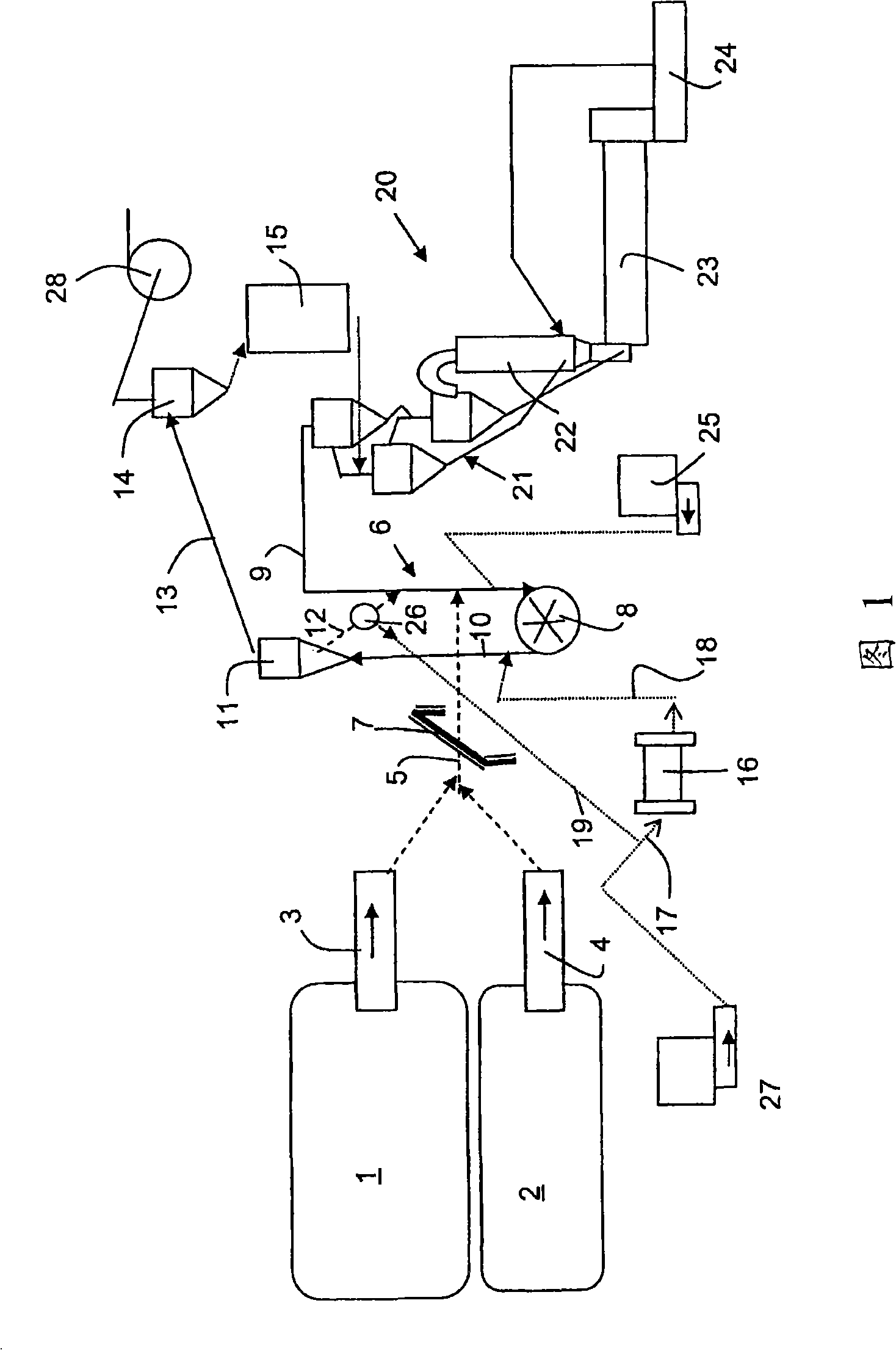

[0012] The apparatus shown comprises: two homogenization bins 1 and 2 for wet limestone, chalk, marl, clay and similar materials excavated from the quarry, for feeding raw materials from said bins 1 and 2 To the batching plants 3 and 4 of the belt conveyor 5 which conveys the raw material to the drying crusher unit 6 . The device comprises an analyzer 7 for analyzing the composition of the raw material and for calibrating the dosing devices 3 and 4 in order to predetermine the correct chemical composition of the raw material. The shown dry-crusher unit 6 comprises a dry-crusher 8 which receives hot discharge gas from a subsequent kiln system 20 via a pipe 9 and a discharge duct 10 which removes the crushed material in suspended form. From the dry crusher 8 to the separator 11. In the separator 11 the material is separated into a coarse fraction and a fine fraction, the coarse fraction is returned via the duct 12 to the duct 9 and from there to the dry crusher for further Dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com