Wafer transmission system

A chip transfer system and chip technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of affecting the output rate of the machine and reducing the processing capacity of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

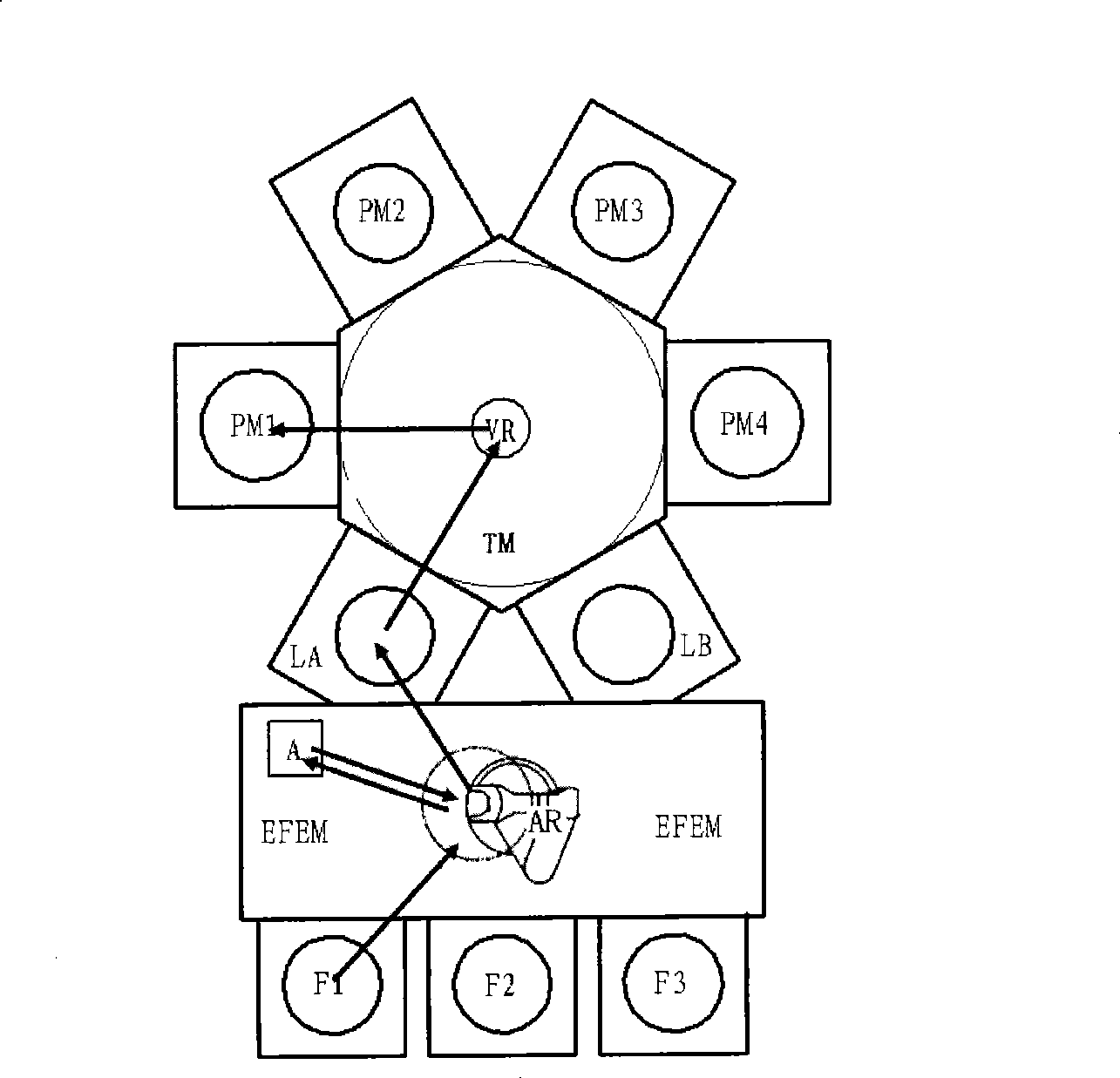

[0021] A preferred embodiment of the wafer transfer system of the present invention is as image 3 As shown, it includes a vacuum transfer chamber TM, and the vacuum transfer chamber TM is connected with multiple chambers, including target processing chambers PM1, PM2, PM3, PM4, vacuum transition load locks LA, LB, etc., which can also be connected as required other chambers.

[0022] The vacuum transfer chamber TM is equipped with a vacuum robot VR, which can transfer wafers between multiple chambers, and the wafer channel between the vacuum transfer chamber TM and each chamber is equipped with a sensor for sensing the position of the wafer 8. One or more sensors 8 can be provided at each wafer channel. When the wafer passes through the wafer channel, the sensor can perceive the position information of the wafer, and the transmission system can calibrate the position deviation of the wafer according to the information.

[0023] The sensor 8 can be a photoelectric sensor, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com