Electric capacitor porcelain sleeve and case cap connecting rolling press

A technology of capacitor ceramics and rolling machines, which is applied to stamping machines, presses, capacitors, etc., can solve the problems of unstable product quality, poor sealing performance, and high production costs, and achieve simplified rolling force generation and transmission mechanisms, rolling force Constant, easily adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

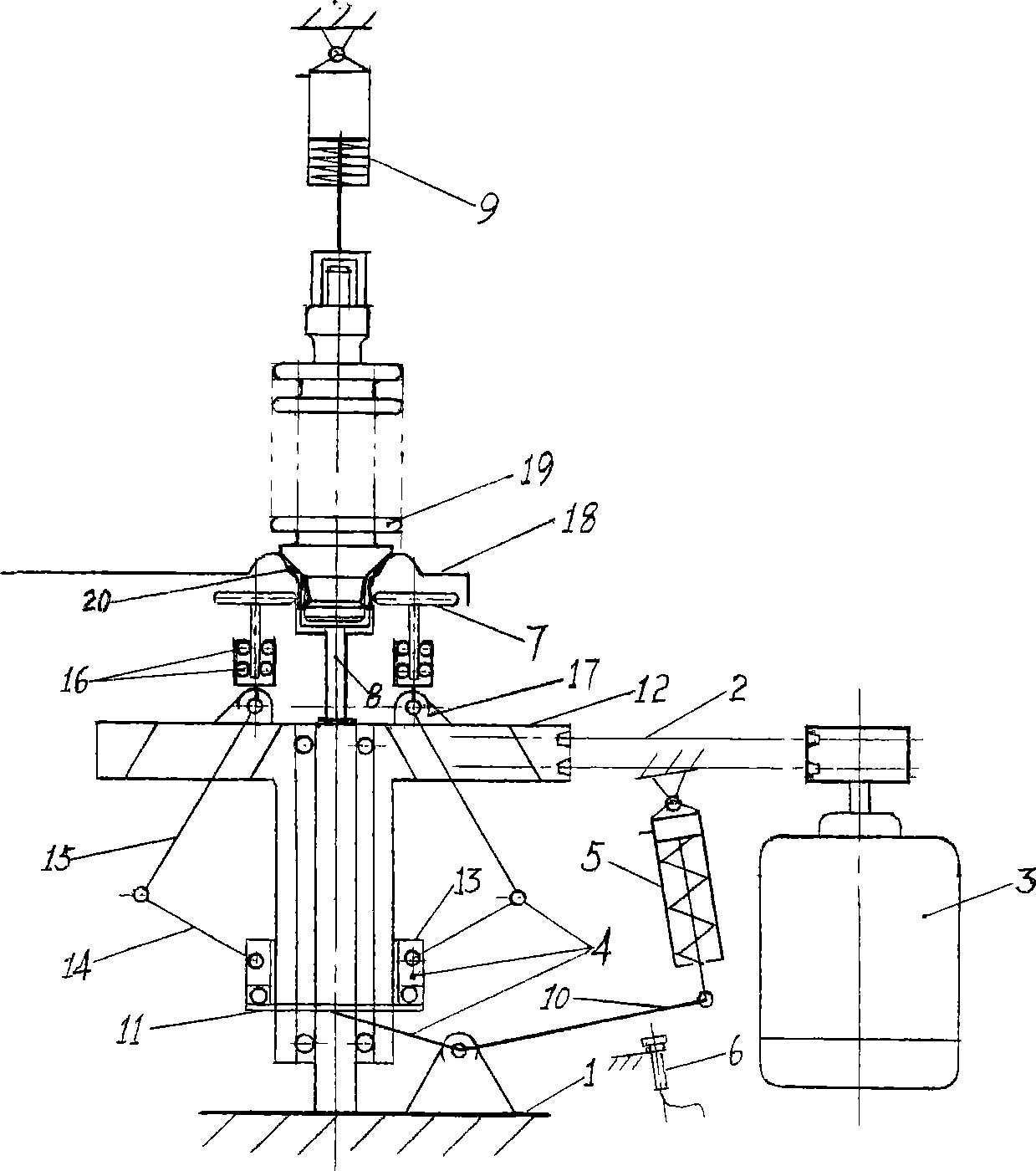

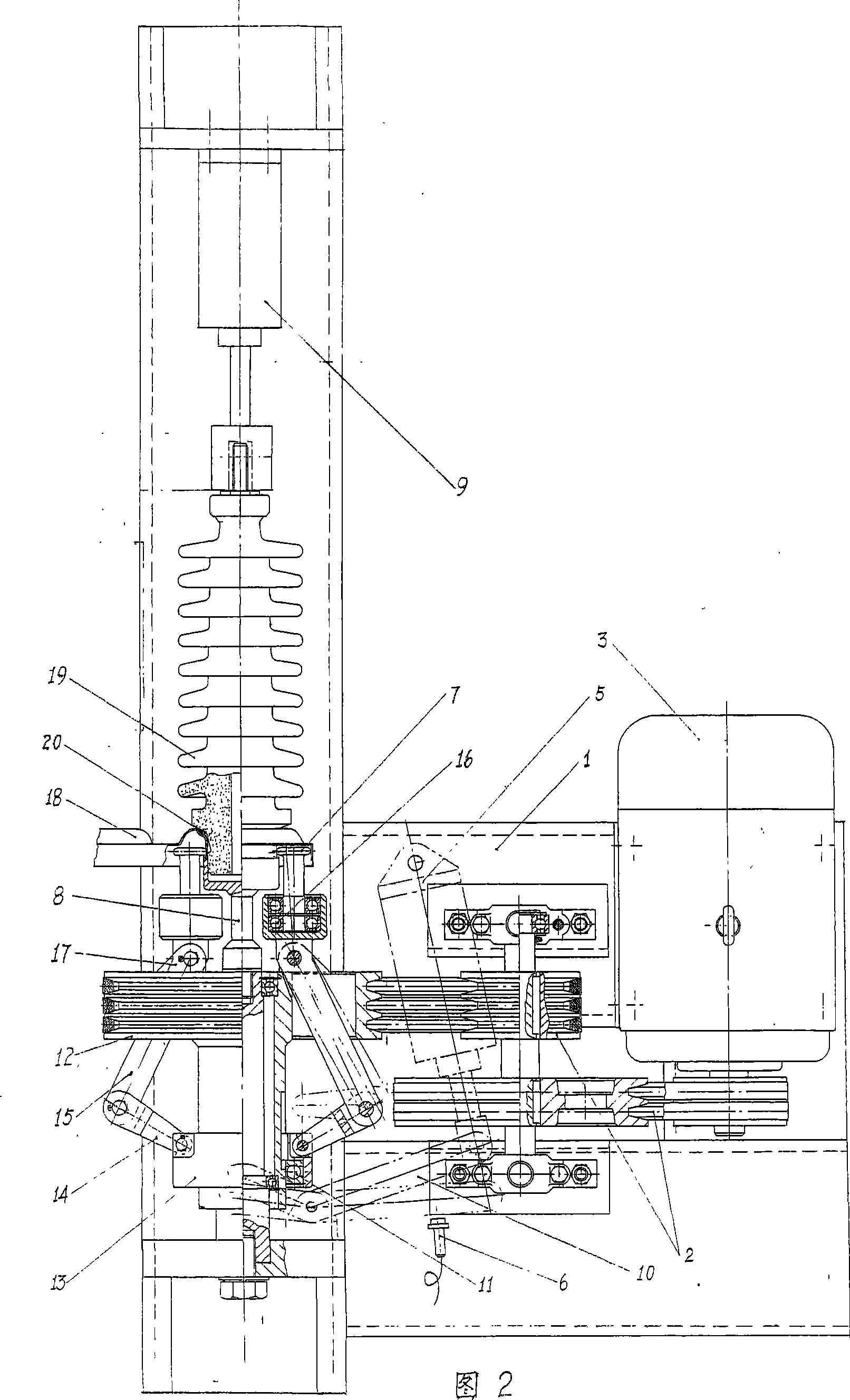

[0015] Such as figure 1 As shown, on the frame 1, the rotary roller seat reduction transmission system 2 and its drive motor 3 made of two-stage V-shaped belts are fixed. The rolling force that is also fixed on the frame 1 produces the cylinder 5, and its cylinder rod is connected with the lever 10 with a rotating shaft. On the sliding sleeve 13 which rotates synchronously with the two roller seat fixing parts 12, the sliding sleeve 13 can slide upwards along the shaft sleeve of the part 12 under the action of the rolling force. 14, just transfer the rolling force to the connecting rod 15 connected with the rotating shaft, the connecting rod 15 with the roller seat fixed on the three upper ends is below the roller seat, and three pairs of supports evenly distributed on the circular surface of the rotating shaft and its fixing part 12 17 is connected, and connecting rod 15 is just with this three pairs of bearings as fulcrum, and rolling force is delivered on the roller seat o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com