Super capacitor using mono-layer graphite as electrode material

A supercapacitor and single-layer graphite technology, applied in the direction of electrolytic capacitors, capacitors, hybrid capacitors, etc., can solve the problems of high cost and unsuitable for large-scale industrial applications, achieve high energy density, reduce ion migration energy barrier, and large The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation of soluble single-layer graphite oxide material

[0027] References for the preparation of soluble single-layer graphite oxide materials (Evaluation of Solution-ProcessedReduced Graphene Oxide Films as Transparent Conductors, Héctor A.Becerril, JieMao, unfeng Liu, Randall M.Stoltenberg, Zhenan Bao, and Yongsheng Chen, AcsNano, 2(3 ), 463-470 (2008). The soluble single-layer graphite oxide material obtained therein can be dried through high-speed centrifugal layering to obtain soluble single-layer graphite oxide materials with different sheet numbers and sizes, thereby obtaining single-layer graphite materials with different specific surface areas. At 8000 r / min, 16 mg / ml aqueous solution of soluble single-layer graphite oxide material was centrifuged at high speed for 60 minutes to obtain the lower layer of solid, which was collected as the first layer of product, and the size of the flakes was 2 μm 2 ~400μm 2 Left and right distribution; the upper layer...

Embodiment 2

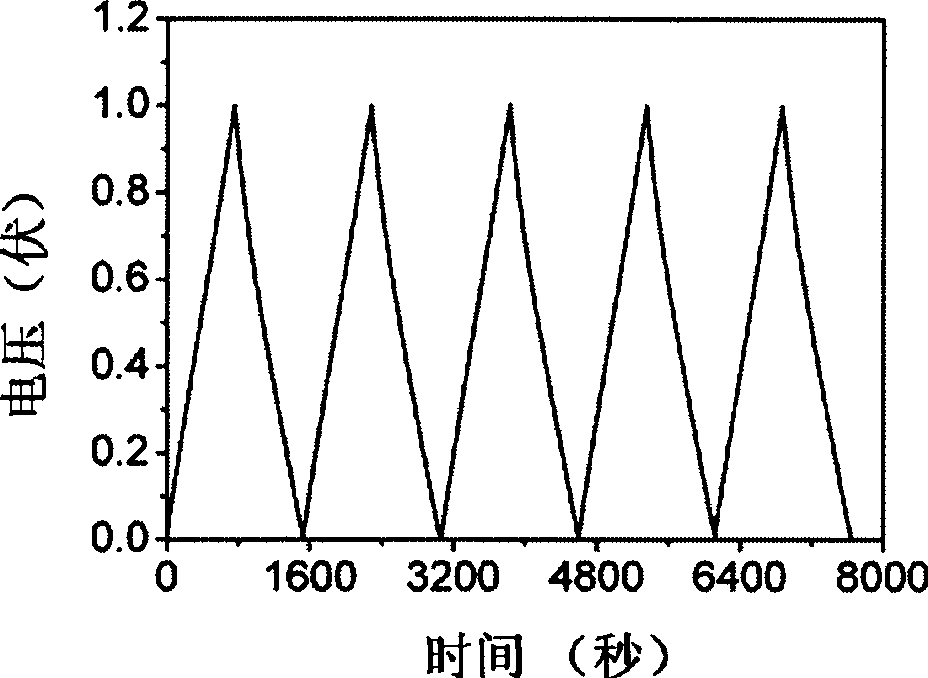

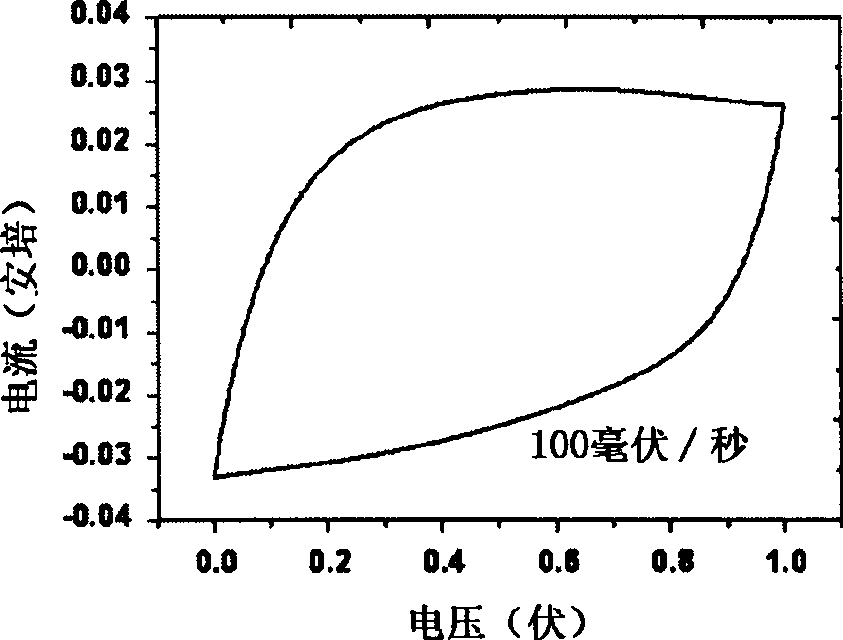

[0032] The reduced single-layer graphite obtained in embodiment 1 (the third layer single-layer graphite oxide product, flake size is at 300nm 2 ~800nm 2 Between) the solid powder obtained after the material is dried at low temperature is pressed on a nickel foam collector plate (diameter 13cm,) to make a circular electrode sheet, and the mass of the active material is about 7 mg; two electrode sheets with similar masses are placed face to face, The middle is separated by a hydrophilic porous diaphragm, and 30wt% KOH electrolyte is added dropwise and then packaged into a button battery case to obtain a supercapacitor. The supercapacitor prepared in this example has a specific capacitance of 180 F / g, a specific power of 18.3 kW / kg, and an energy density of 23.5 Wh / kg.

Embodiment 3

[0034] The reduced single-layer graphite obtained in embodiment 1 (the third layer single-layer graphite oxide product, flake size is at 300nm 2 ~800nm 2 Between) The solid powder obtained after the material is dried at low temperature is pressed on the foamed nickel collector plate under a certain pressure (about 160MPa, the same below) to make a circular electrode sheet with a diameter of 13cm, and the mass of the active material is about 7mg; Two electrode sheets of similar mass are placed face to face, separated by a hydrophilic porous diaphragm (polypropylene film) in the middle, and 5wt% KOH electrolyte is added dropwise and packaged into a button battery case to obtain a supercapacitor. The specific capacitance of the supercapacitor prepared in this example is 103F / g, the specific power is 10.5kW / kg, and the energy density reaches 14.3Wh / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com