Molding and punching tool for producing thin-film sheet and manufacture method of thin-film sheet

A technology for punching dies and film sheets, which is used in the fields of forming and punching dies for manufacturing film sheets and film sheet manufacturing to achieve the effects of reducing the number of dies, reducing operators and equipment, and reducing positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

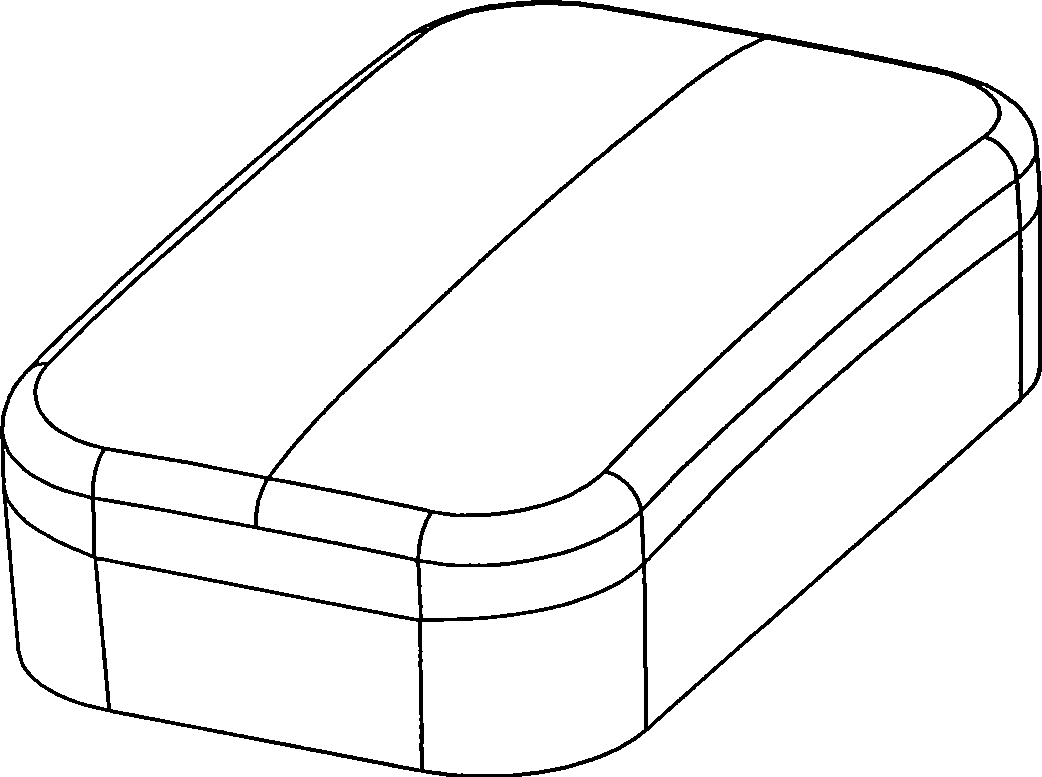

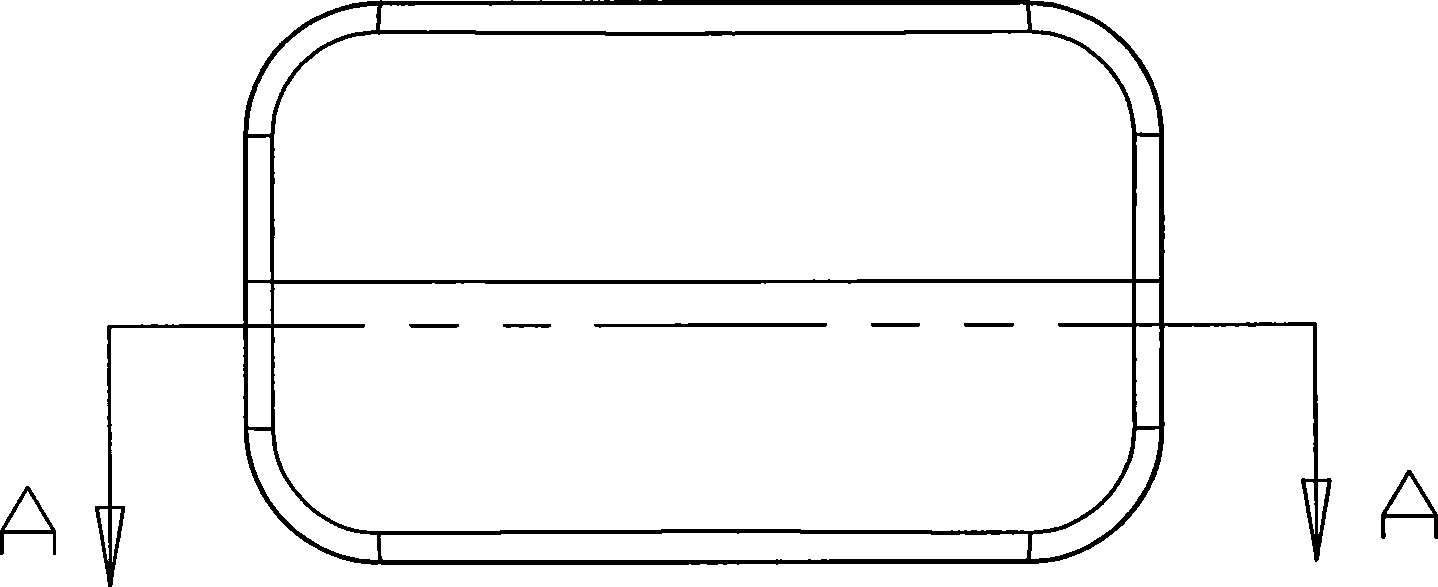

[0051] Such as Figure 1-3 Shown is the first embodiment of the forming and die-cutting die of the present invention for manufacturing the film sheet, which is used to manufacture the film sheet of this shape, and the film sheet is a square shell.

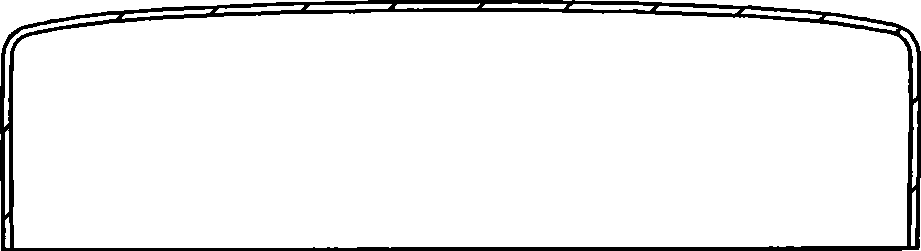

[0052] Such as Figure 4-7 As shown, the forming and die-cutting die for manufacturing film sheet includes an upper die assembly and a lower die assembly that cooperate with each other. The mold for manufacturing film sheets also includes a first top plate 34 fixed on the upper mold assembly.

[0053] Wherein, the upper mold assembly includes a first upper mold fixing plate 36 below the first top plate 34 , a first upper mold insert 32 , a second upper mold insert 33 , and a first upper mold 37 . The first upper mold fixed plate 36 is fixed together with the first top plate 34 by screws, and a through hole is provided in the first upper mold fixed plate 36 the inside, and the first upper mold insert 32 is matched and installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com