Worm shaft of beam drill

A technology of radial drilling machine and worm shaft, which is applied to the components of boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc., can solve the problems of poor processing technology, leakage, visual fatigue, etc. The effect of shaking and flickering, solving safety hazards, and improving craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

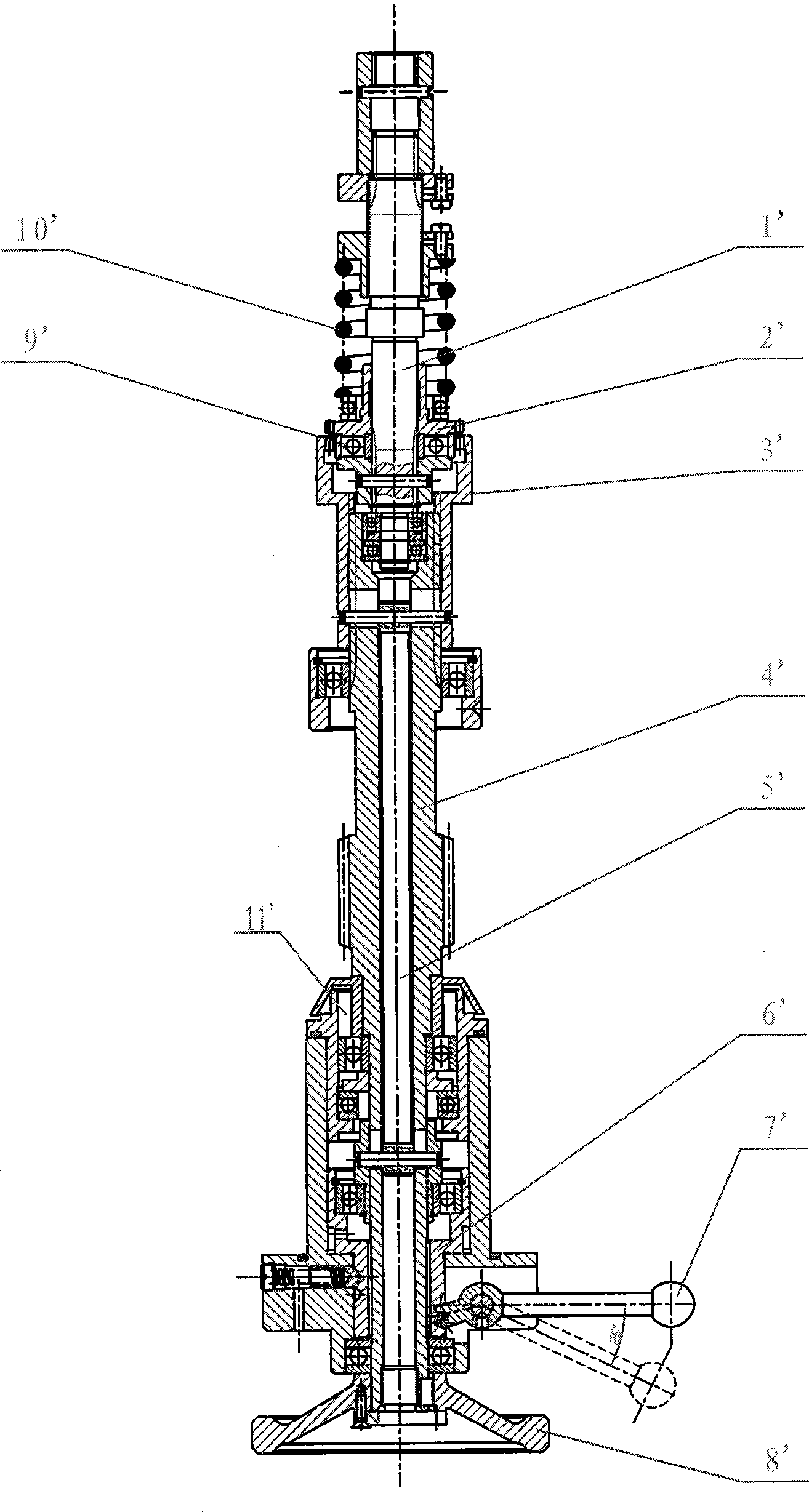

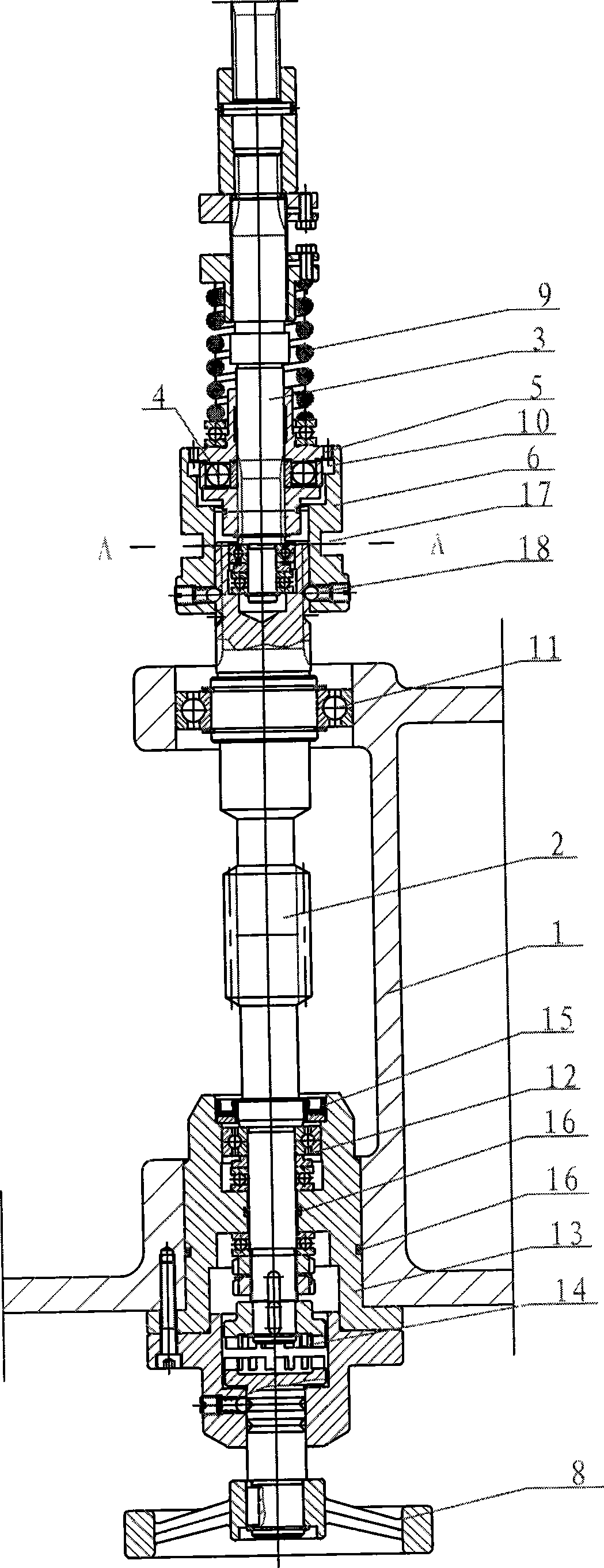

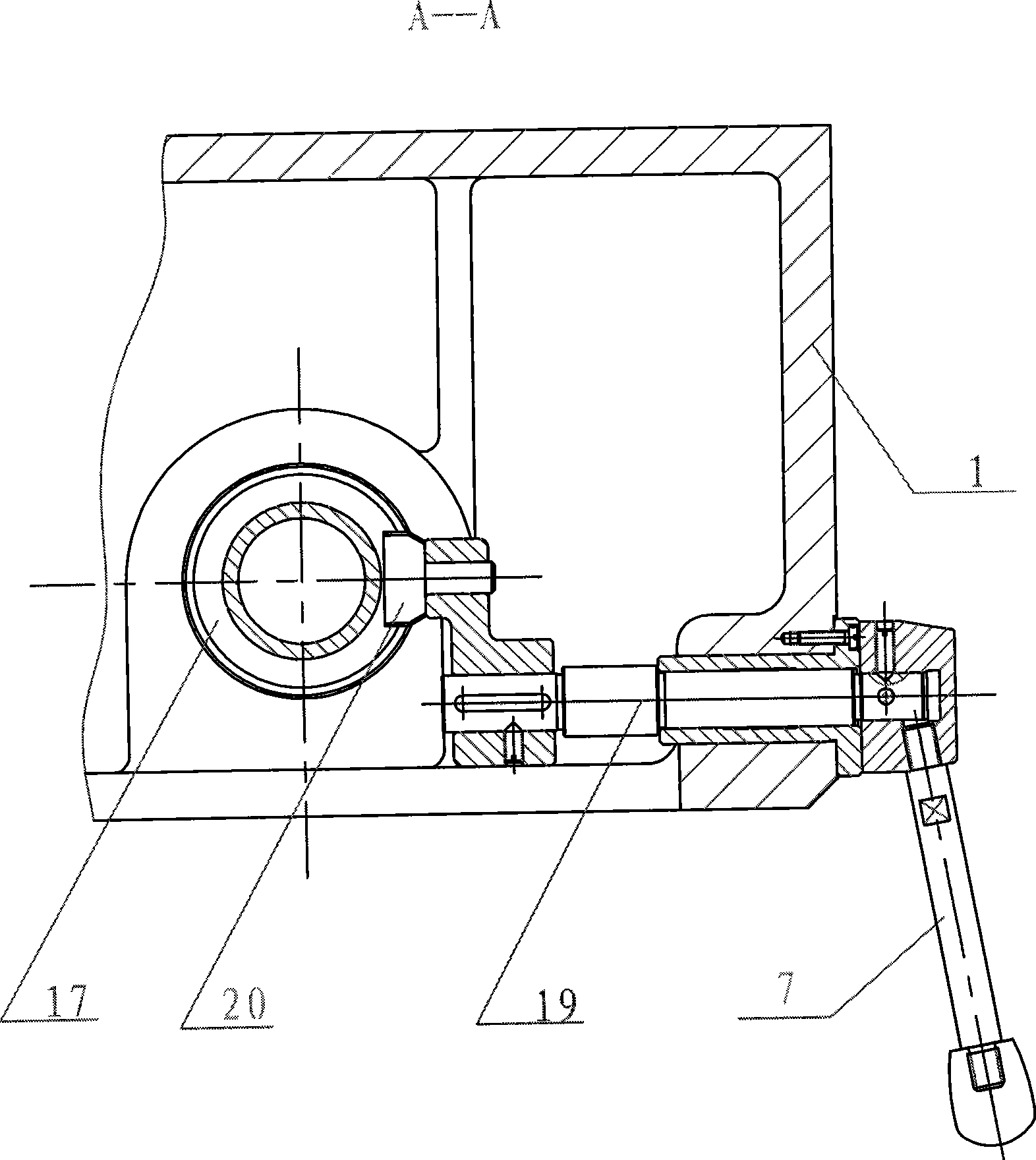

[0025] Such as Figures 2 to 4 As shown, the present invention is located in the right side of the spindle box 1 of the radial arm drilling machine, including the worm shaft 2, the spline shaft 3, the steel ball insurance clutch 4, the external gear 5, the internal gear 6, the handle 7 and the hand wheel 8, the The spline shaft 3 is sleeved and fixed with a spring 9, a steel ball insurance clutch 4 is provided between the spline shaft 3 and the external gear 5, the internal gear 6 has a tooth groove 10 matching the external gear 5, and the worm shaft 2 is a short solid shaft, the upper end of the worm shaft 2 is spline connected with the internal gear 6, the upper part is sleeved and fixed on the headstock 1 by the bearing I11, the lower part is connected with the headstock bearing seat 13 through the bearing II12, and the lower end is through the side The tooth clutch 14 is connected with the handwheel 8 . A rotary seal 15 is provided between the worm shaft 2 and the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com