Electronic photographing photosensitive component, processing cartridge, and electronic photographing device

An electrophotographic and photosensitive member technology, applied in optics, electrographics, instruments, etc., can solve the problem of not specifically disclosing the details of the surface profile of the electrophotographic photosensitive member.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

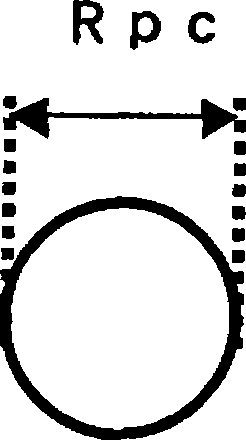

[0158] An aluminum cylinder with a diameter of 30 mm and a length of 357.5 mm that had been subjected to surface cutting processing was used as the support (cylindrical support).

[0159] Next, a mixture composed of the following components was dispersed by a ball mill for about 20 hours to prepare a conductive layer coating liquid.

[0160] 60 parts powder composed of barium sulfate particles with tin oxide coating

[0161] (Trade name: PASTRAN PC1; purchased from Mitsui Mining & Smelting Co., Ltd.)

[0162] 15 parts of titanium oxide

[0163] (Trade name: TITANIX JR; purchased from Tayca Corporation)

[0164] 43 parts of resole phenolic resin

[0165] (Trade name: PHENOLITE J-325; purchased from Dainippon Ink & Chemicals, Incorporated; solid content: 70%)

[0166] Silicone oil 0.015 parts

[0167] (Trade name: SH28PA; purchased from Toray Silicone Co., Ltd.)

[0168] Silicone resin 3.6 parts

[0169] (Trade name: TOSPEARL 120; purchased from Toshiba Silicone Co., Ltd.)

[0170] ...

Embodiment 2

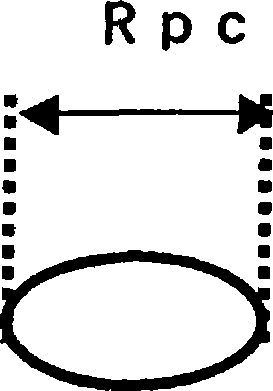

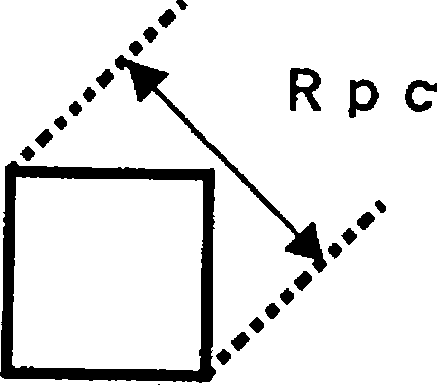

[0213] In addition to the mold used in Example 1, the Picture 12 The electrophotographic photosensitive member was produced in the same manner as in Example 1, except that the height of 3.0 μm represented by F in F became 2.4 μm, and its surface was treated in the same manner as in Example 1. The surface profile was measured in the same manner as in Example 1 to confirm that a cylindrical depression was formed. The measurement results are shown in Table 1. The depressed portions are formed at intervals of 1.0 μm. The percentage of the open area is calculated and found to be 20%. The elastic deformation modulus and the generalized hardness were measured in the same manner as in Example 1. As a result, the elastic deformation modulus value is 55%, and the generalized hardness value is 180N / mm 2 . The performance of the electrophotographic photosensitive member was also evaluated in the same manner as in Example 1. The results are shown in Table 1.

Embodiment 3

[0215] In addition to the mold used in Example 1, the Picture 12 Except that the major axis diameter indicated by D becomes 0.5 μm, the interval 1.0 μm indicated by E becomes 0.5 μm, and the height indicated by F becomes 2.0 μm, the same as in Example 1 is adopted. The electrophotographic photosensitive member was produced by the method, and its surface was treated in the same manner as in Example 1. The surface profile was measured in the same manner as in Example 1 to confirm that a cylindrical depression was formed. The measurement results are shown in Table 1. The depressed portions are formed at intervals of 0.5 μm. The percentage of the open area is calculated and found to be 20%. The elastic deformation modulus and the generalized hardness were measured in the same manner as in Example 1. As a result, the elastic deformation modulus value is 55%, and the generalized hardness value is 180N / mm 2 . The performance of the electrophotographic photosensitive member was also eval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com