Lens system

A lens system and lens technology, applied in optical components, optics, instruments, etc., to achieve good image quality, miniaturization, and small length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

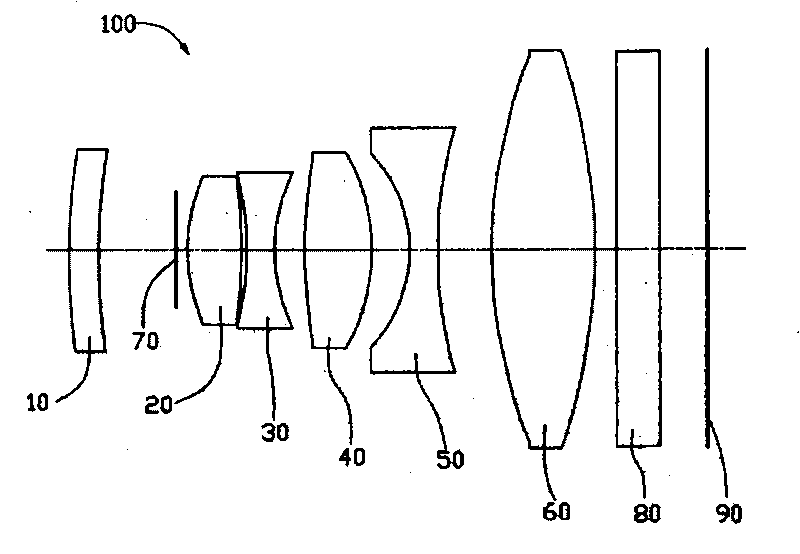

[0037] Each optical element of the lens system 100 meets the conditions of Table 1, and its TT=11.64 millimeters (mm); f=6.91mm; f 23 =19.2939mm; FNo=3.19; 2ω=56°.

[0038] Table 1

[0039] lens system 100

[0040] lens system 100

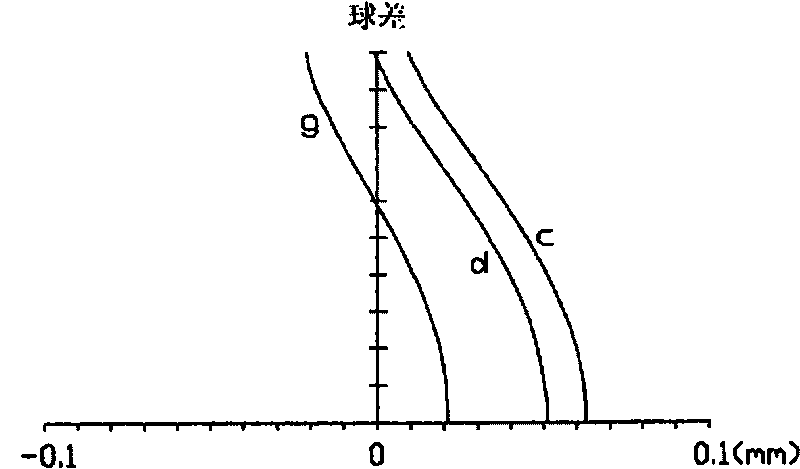

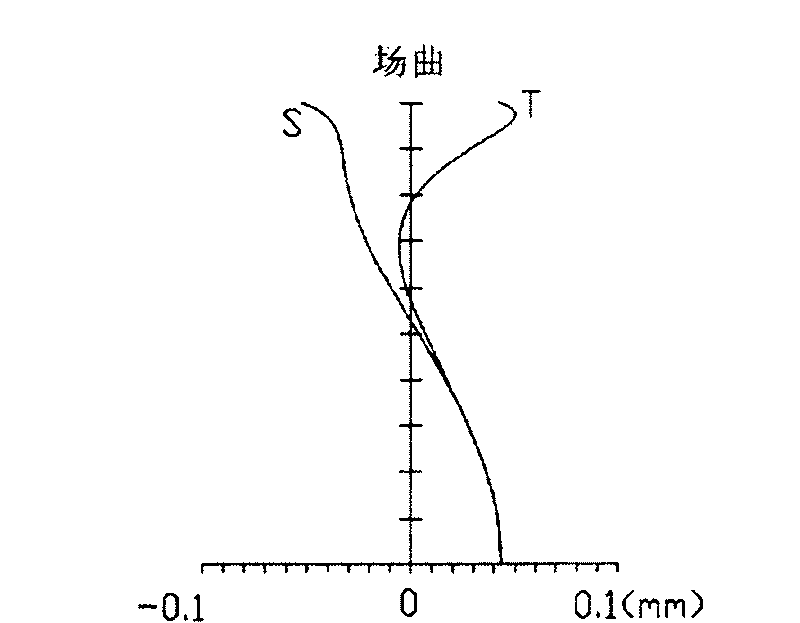

[0041] In the lens system 100 of the first embodiment, the spherical aberration, field curvature and distortion are respectively as follows Figure 2 to Figure 4 shown. figure 2 Among them, the spherical aberration values observed for g-line (wavelength value 435.8 nanometers (nm)), d-line (wavelength value 587.6nm), and c-line (wavelength value 656.3nm) respectively. Generally speaking, the spherical aberration value generated by the lens system 100 of Embodiment 1 for visible light (with a wavelength range between 400nm and 700nm) is within the range of (-0.1mm, 0.1mm), image 3 The S (meridian field curvature value) and T (sagittal field curvature value) are both controlled within the range of (-0.1mm, 0.1mm). Figure ...

Embodiment 2

[0043] Each optical element of the lens system 100 satisfies the conditions of Table 2, and its f=7.098mm; f 23 =18.8125mm; FNo=3.19; 2ω=53.38°.

[0044] Table 2

[0045] lens system 100

Radius of curvature (mm)

Thickness (mm)

subject

gigantic

1000

---

---

The surface of the first lens 10 on the object side

138

0.515

1.48749

70.4058

The image-side surface of the first lens 10

38.5071

1.2933

---

---

Aperture 70

gigantic

0.2166

---

---

The surface of the second lens 20 on the object side

3.434642

0.9954933

1.90217

40.7651

The surface of the second lens 20 on the image side

-12.82318

0.1

---

---

The surface of the third lens 30 on the object side

-6.115171

0.515

1.729672

28.6914

The surface of the third lens 30 on the image side

3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com