Engine gas fuel supply apparatus

A gas fuel and supply device technology, applied to fuel injection devices, oil supply devices, engine components, etc., can solve problems such as valve core movement obstacles, and achieve the effects of preventing poor operation, efficient heating, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

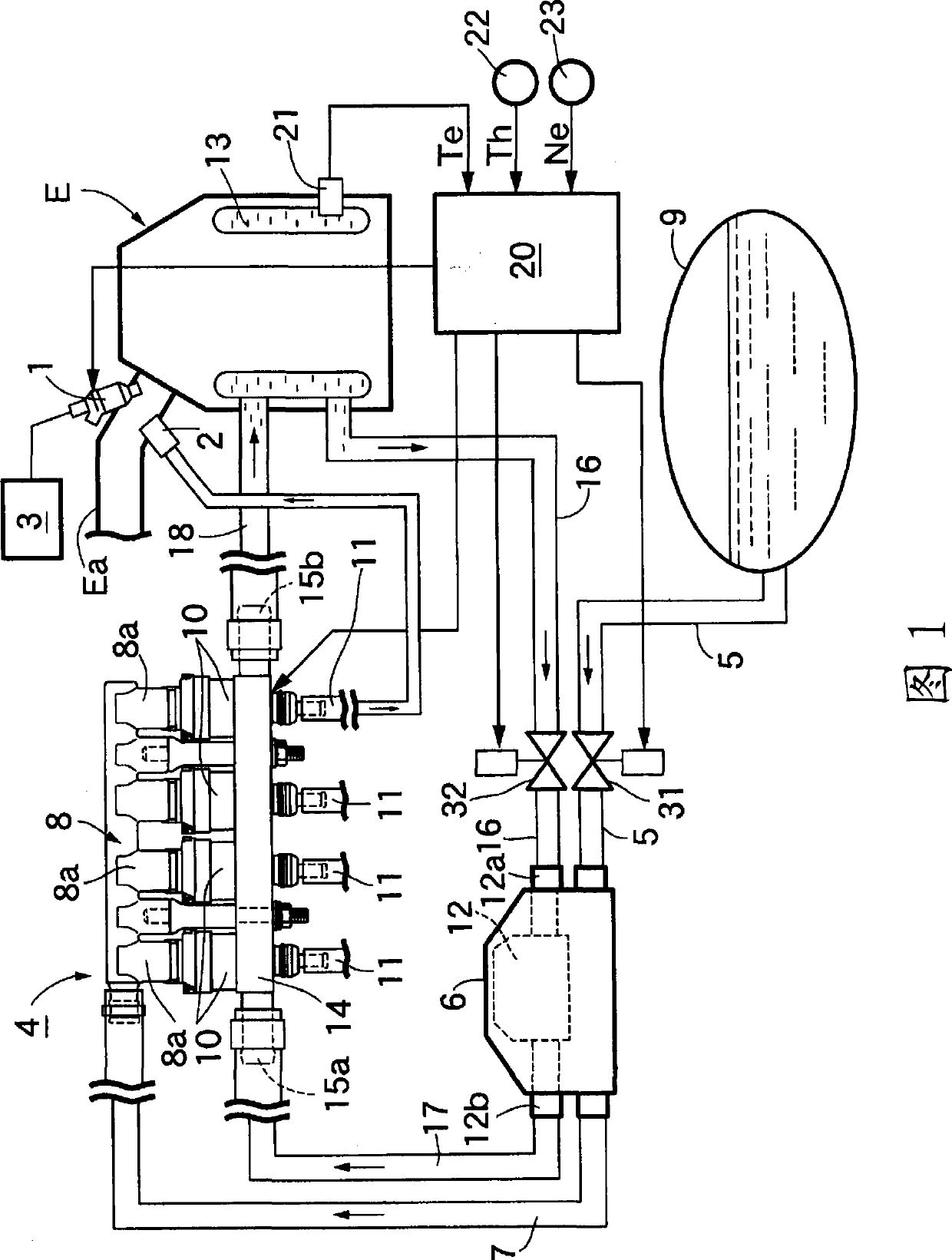

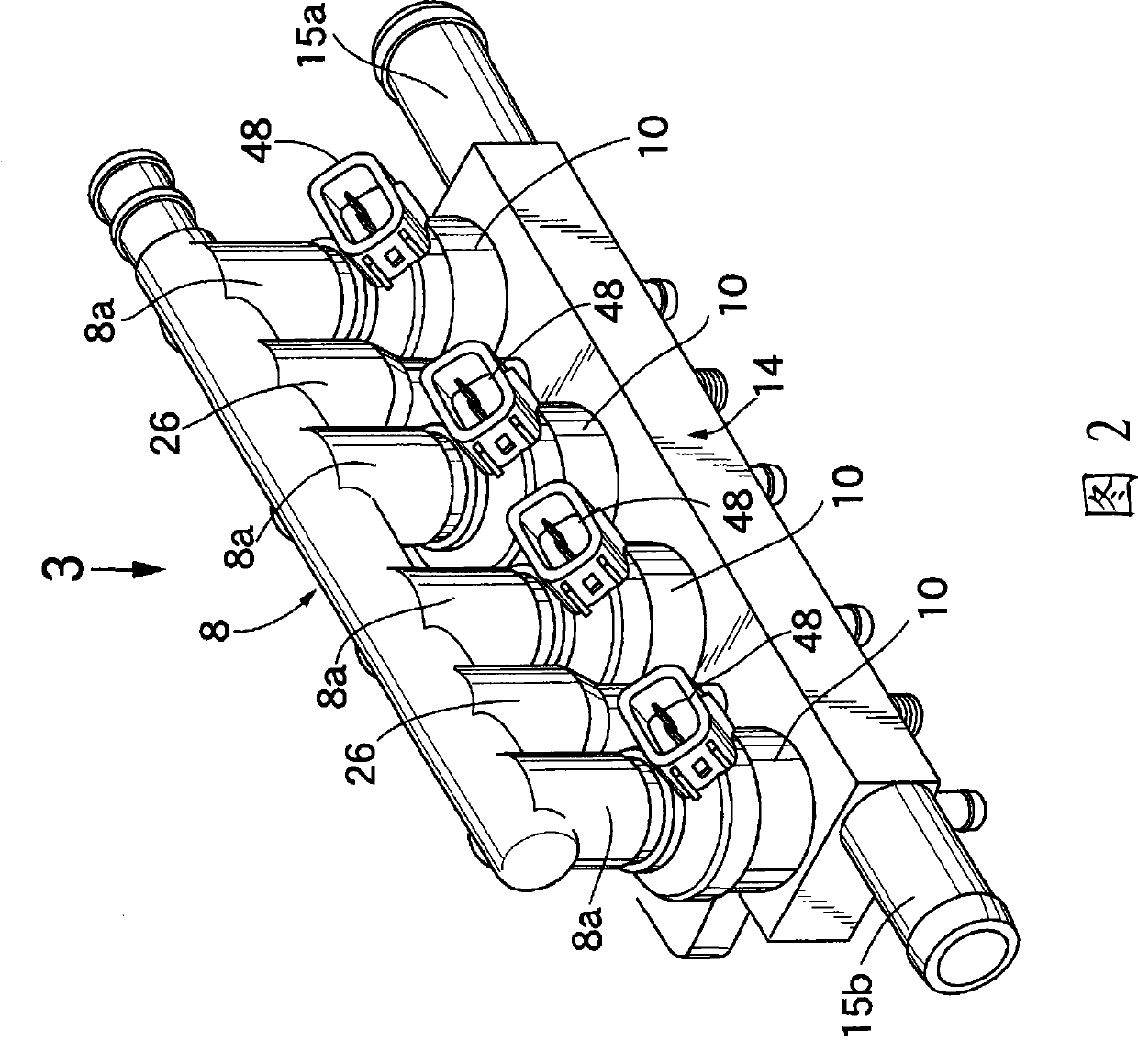

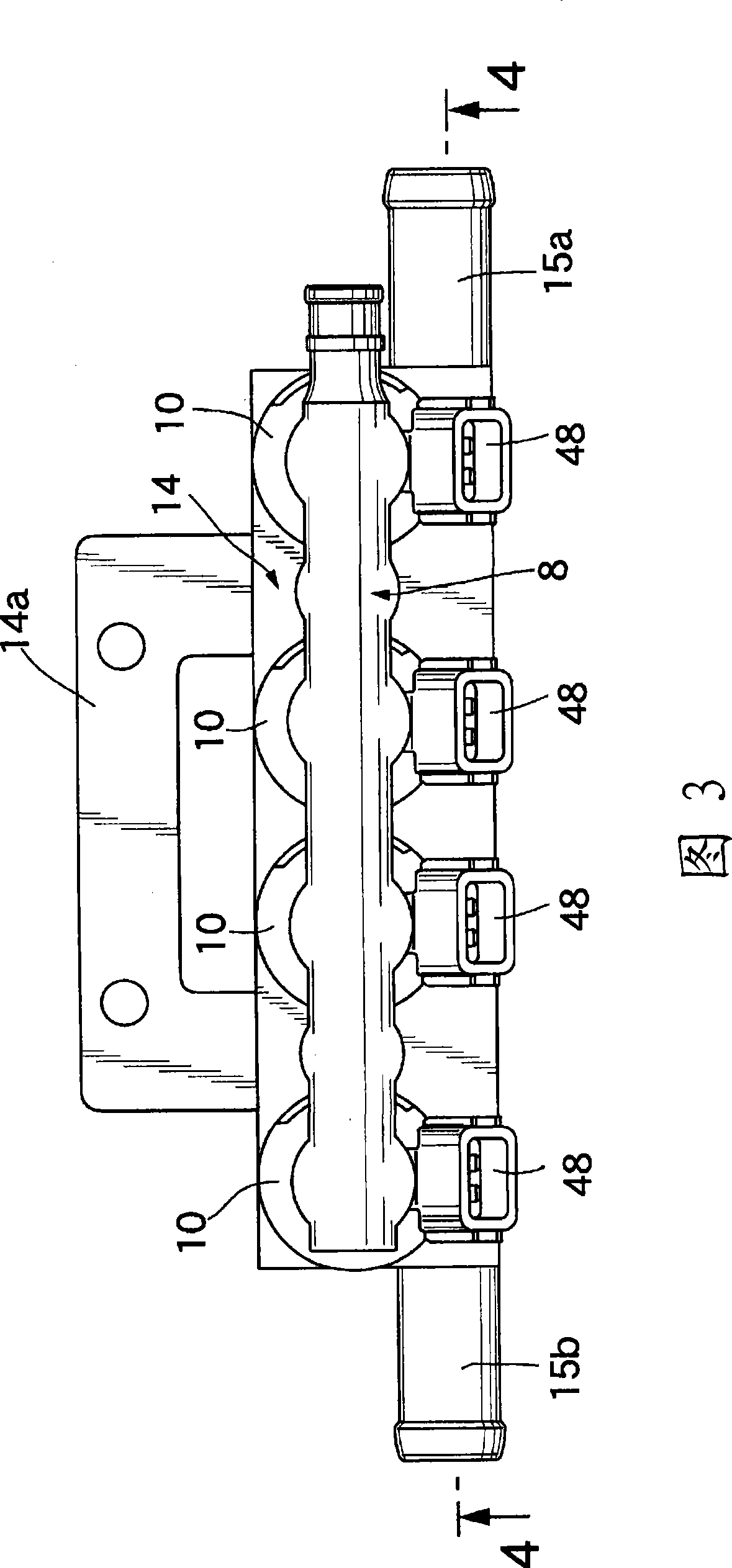

[0039] First of all, in Fig. 1, on the side of the cylinder head of the multi-cylinder engine E are installed: gasoline fuel injection valves 1, 1..., the gasoline fuel injection valves 1, 1... are connected to a plurality of intake pipes corresponding to the number of cylinders Ea, Ea... (only one of them is shown in Fig. 1.), gasoline fuel can be injected towards cylinders corresponding to these intake pipes Ea, Ea...; and gaseous fuel injection cylinders 2, 2..., said gaseous fuel injection cylinders 2, 2... are also injected toward the corresponding cylinders with gas as fuel. On the gasoline fuel injection valve 1, 1..., be connected with known gasoline fuel supply device 3, on the gas fuel injection tube 2, be connected the gas fuel supply device 4 of the present invention that gas such as LPG or CNG supplies as fuel.

[0040] This gaseous fuel supply device 4 has: a gaseous fuel tank 9 (in the illustrated example, filled with LPG liquefied gas); an evaporator 6 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com