Method for measuring thickness of wire-shaped narrowband filtering PSD thermal radiation plate

A technology of linear laser and thermal radiation plate, which is used in measurement devices, optical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

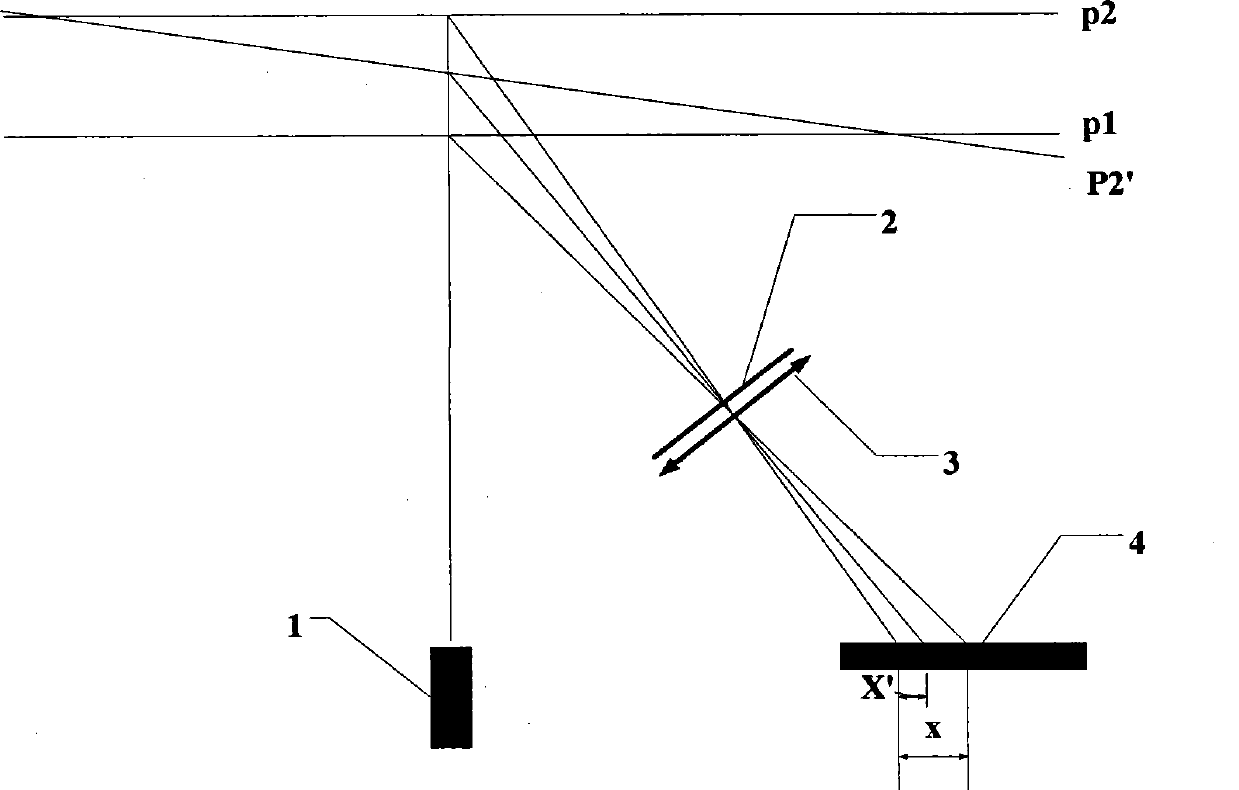

[0051] Embodiment 1: single optical path measurement method

[0052] Such as figure 1 As shown, the present invention uses a linear laser as the light source, and the laser spot is linear, which has its advantages compared with other shapes of lasers. PSD can easily receive the laser reflected by the sample and make the positioning of the spot accurate.

[0053] The rest of the structure is the same as that in the background art, wherein, 1. a linear laser, 2. a narrow-band filter, 3. a lens, and 4. a PSD position sensor.

Embodiment 2

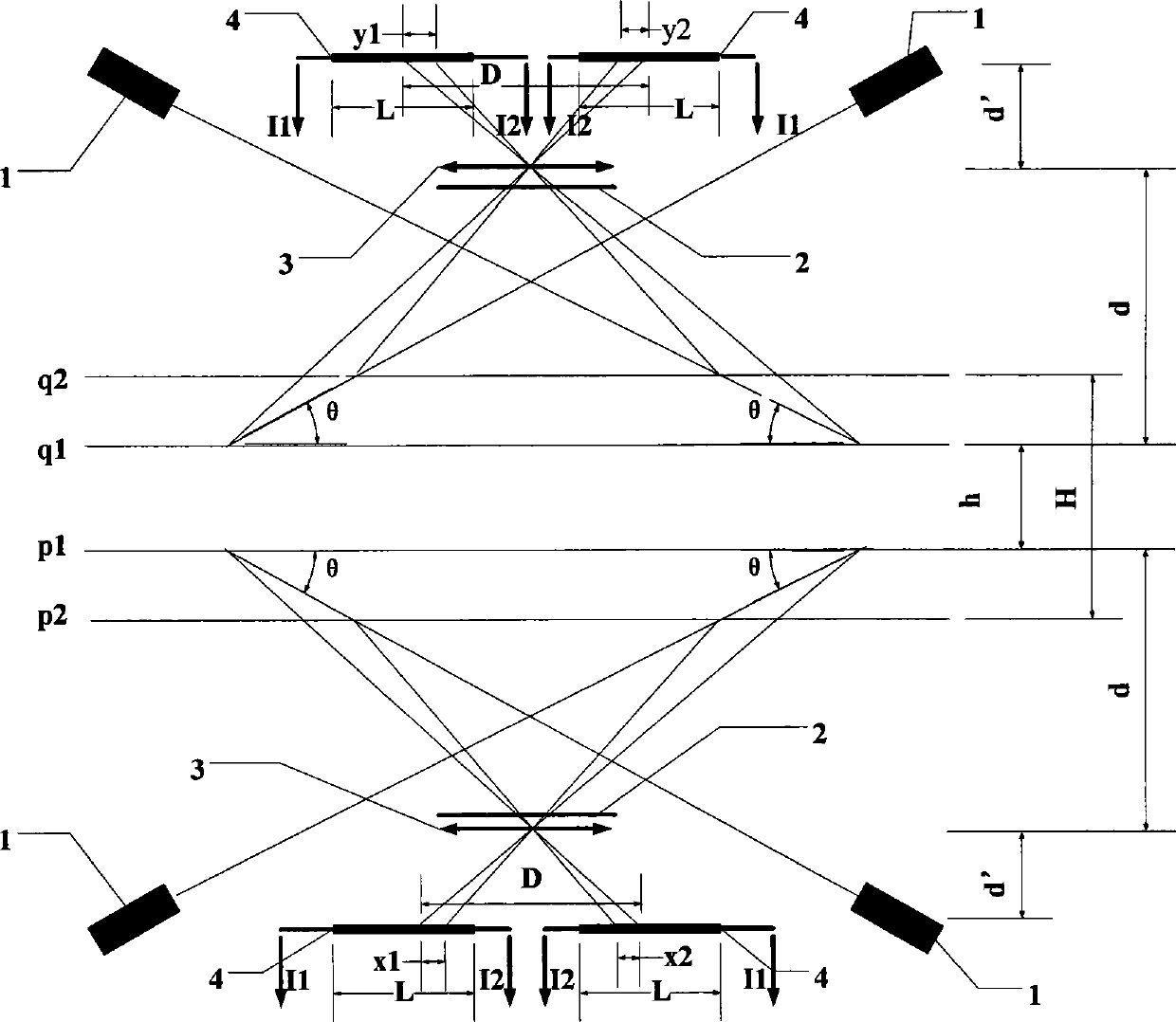

[0054] Embodiment 2: Dual optical path measurement method

[0055] Such as Figure 5 As shown, the sample 12 to be tested is fixed on the displacement frame 10, and the stepper motor 8 drives the displacement frame to move along the guide rail 11 at a certain speed through the transmission shaft 9, so as to realize real-time dynamic measurement of the thickness of the sample to be measured.

[0056] First, the setting and calibration of the measurement optical path, the standard sample of known thickness h is placed on the mobile frame 10, and two pairs of thickness measuring probes 5 are symmetrically arranged on both sides of the standard sample. Optical sheet, lens, PSD position sensor and signal processing circuit board; make the linear laser inside the thickness measuring probe emit linear laser and shoot it on the standard sample, and the reflected laser light passes through the narrow-band filter inside the probe and then converges through the lens. Finally, a spot is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com