Hydraulic-mechanical integrated sand discharge apparatus

A mechanical and hydraulic technology, applied in the field of water conservancy and hydropower engineering, can solve the problems of low sand discharge efficiency, limited volume of sand discharge funnel, etc., and achieve good social and economic benefits, high sand discharge efficiency, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

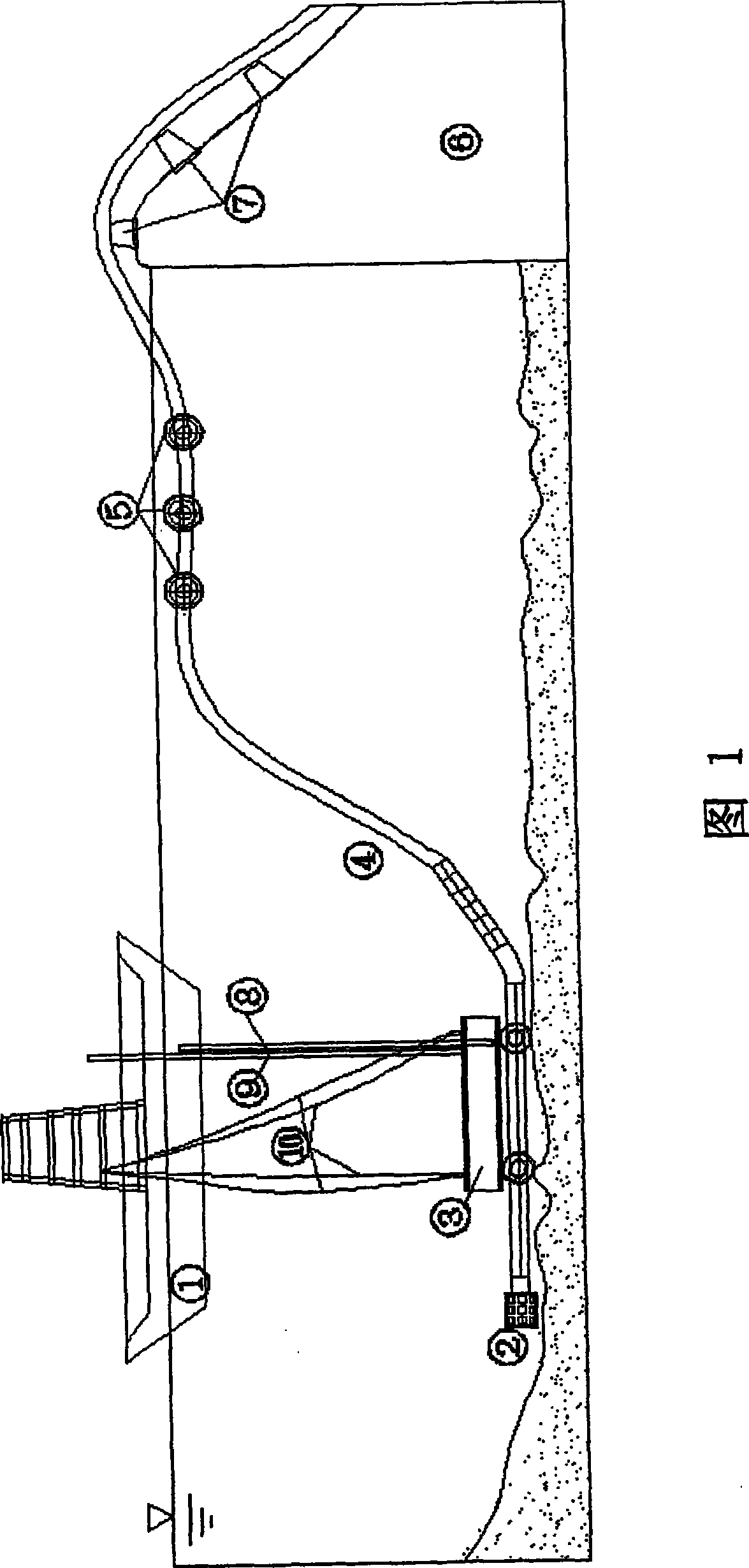

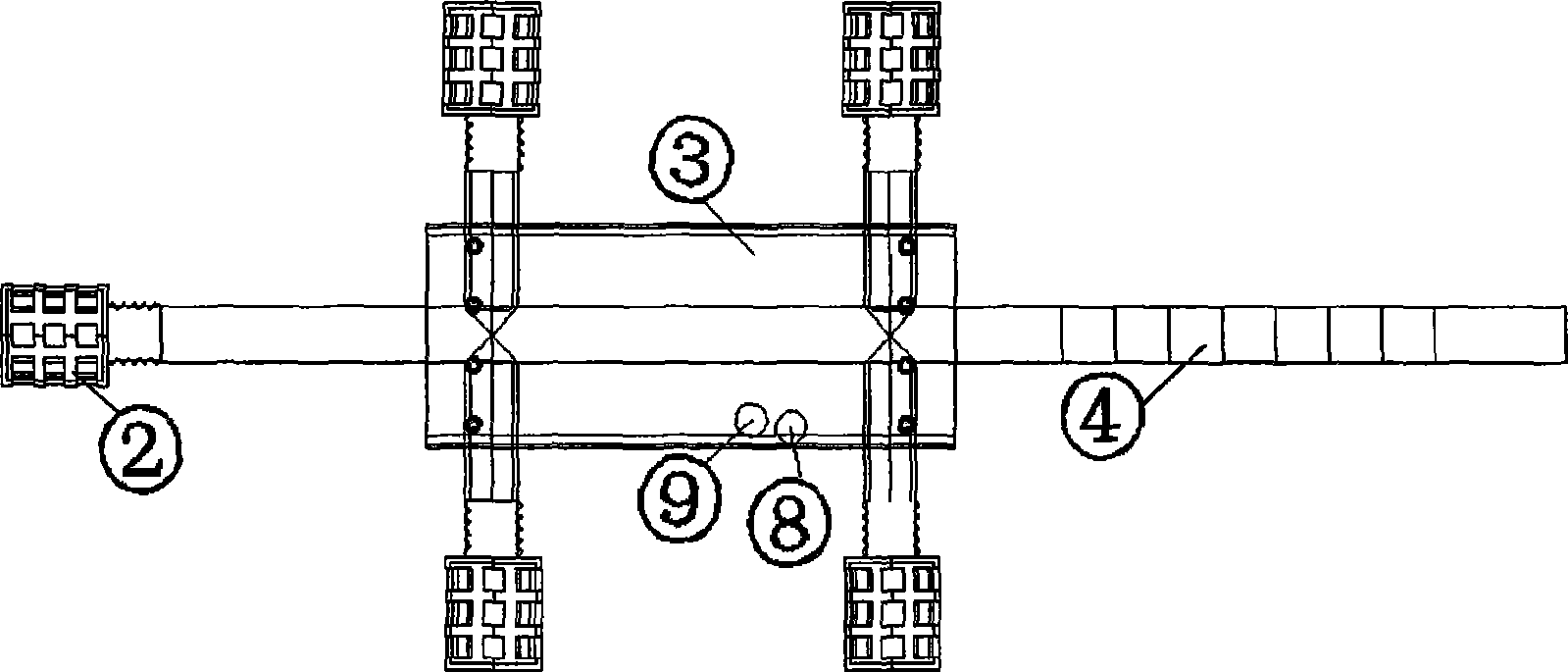

[0017] Example: See Figure 1 and figure 2 , in the figure, a sand suction device 2 is installed at the head end of the siphon type sand delivery pipe 4 of the hydraulic-mechanical integrated sand removal device, and the sand suction device 2 is fixed with a submersible box 3, and the submersible box 3 is connected to the water surface through a steel cable 10. The tugboat 1 is connected to facilitate movement, and the submersible tank 3 is provided with an air intake pipe 9 and a discharge pipe 8. The control valves of the air intake pipe 9 and the discharge pipe 8 are arranged on the tugboat 1, and the air intake pipe 9 is connected with the pressure gas source and the water source respectively. Conversion is communicated, is convenient to ventilate or pass water in the intake pipe 9. The tail end of the siphon sand delivery pipe 4 is fixed on the pier 7 provided on the dam body 6 . In order to increase the buoyancy of the tail end of the siphon sand delivery pipe 4, a buoy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com