Heat radiation model set and its fin group

A heat dissipation module and heat sink technology, which is applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve the problem of affecting the heat dissipation performance of the heat dissipation module, the heat of the heat sink cannot be removed in time, Inability to make full use of the heat dissipation fan to cool the airflow and other issues, so as to improve the heat dissipation performance and increase the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

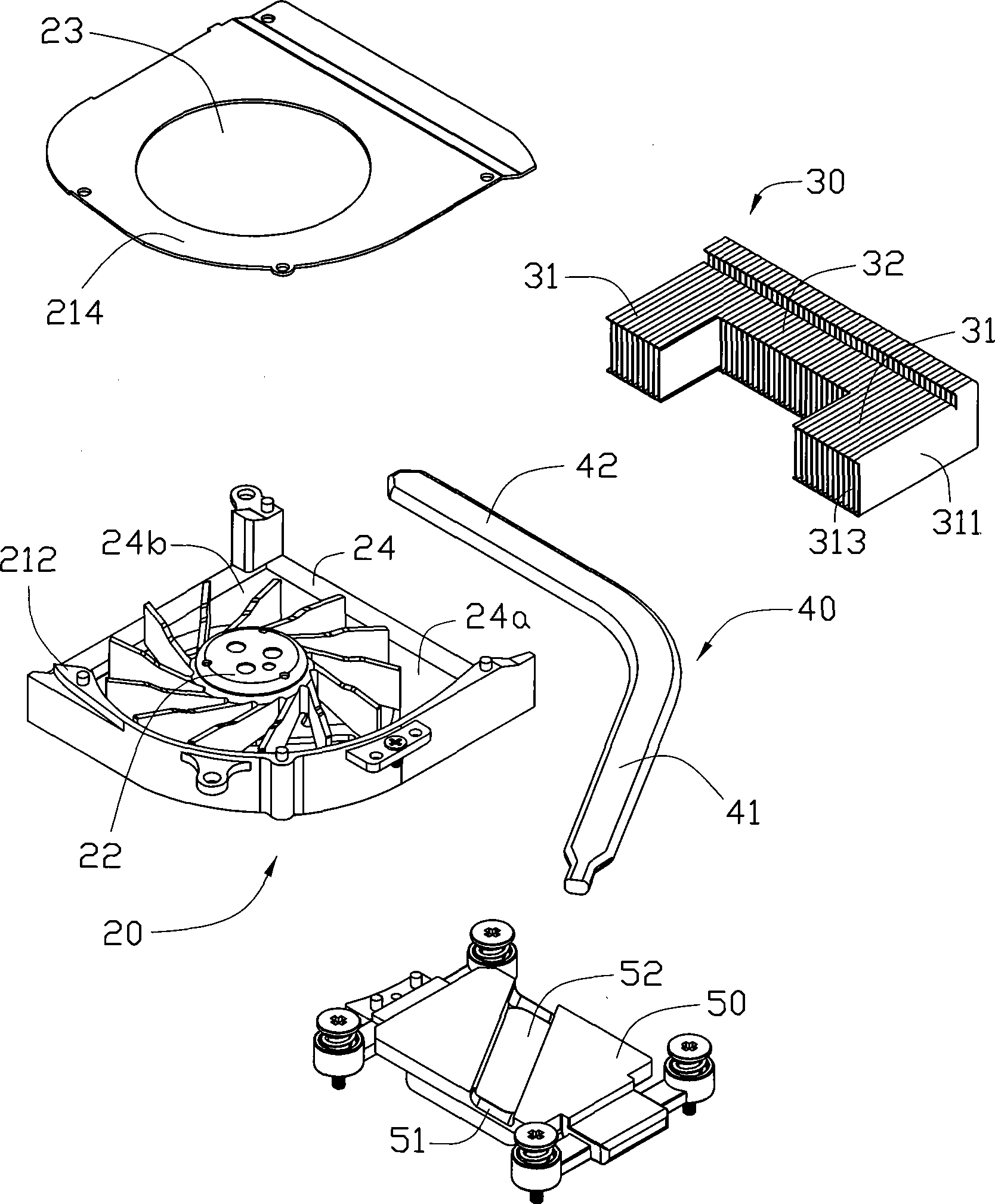

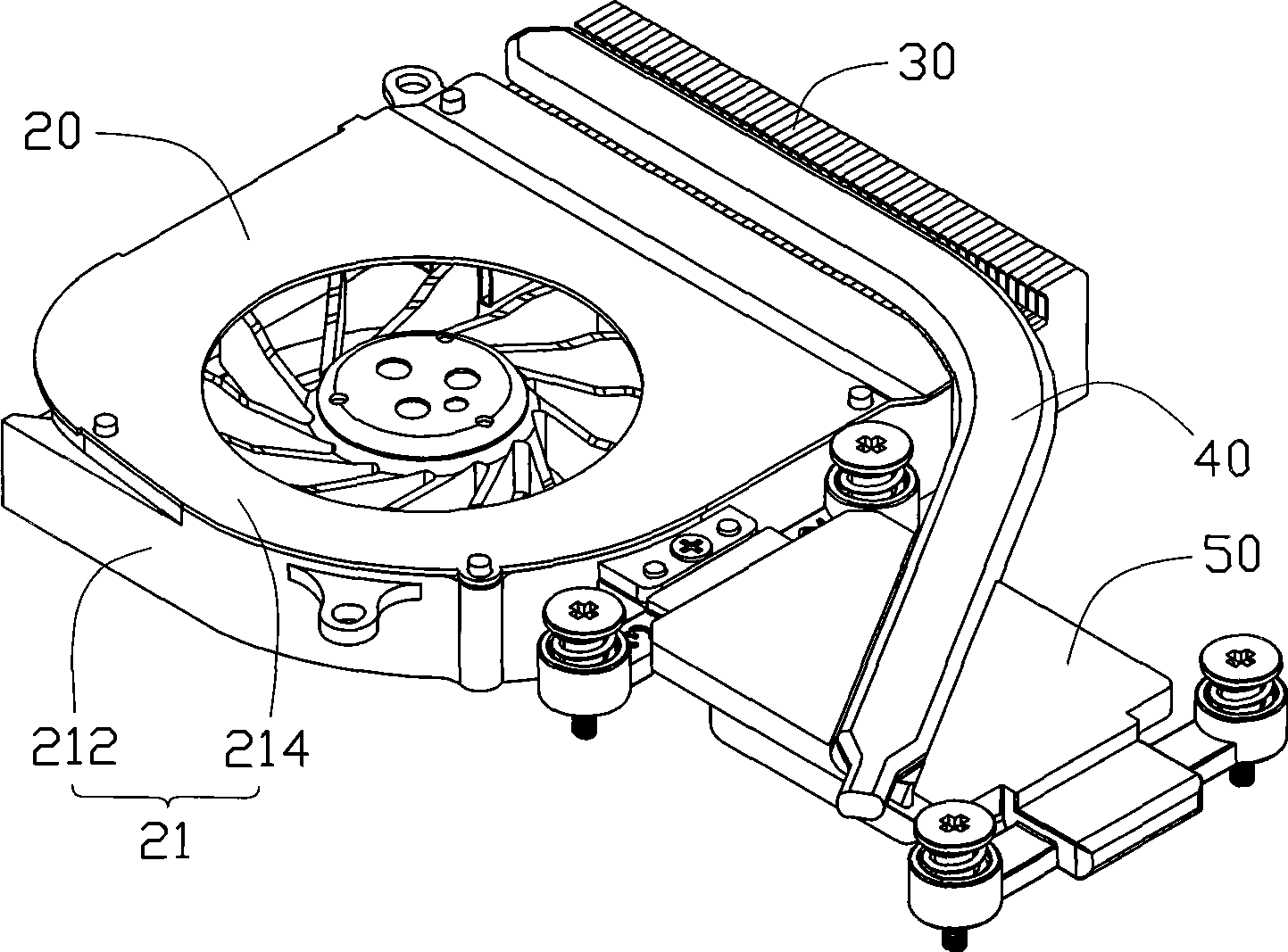

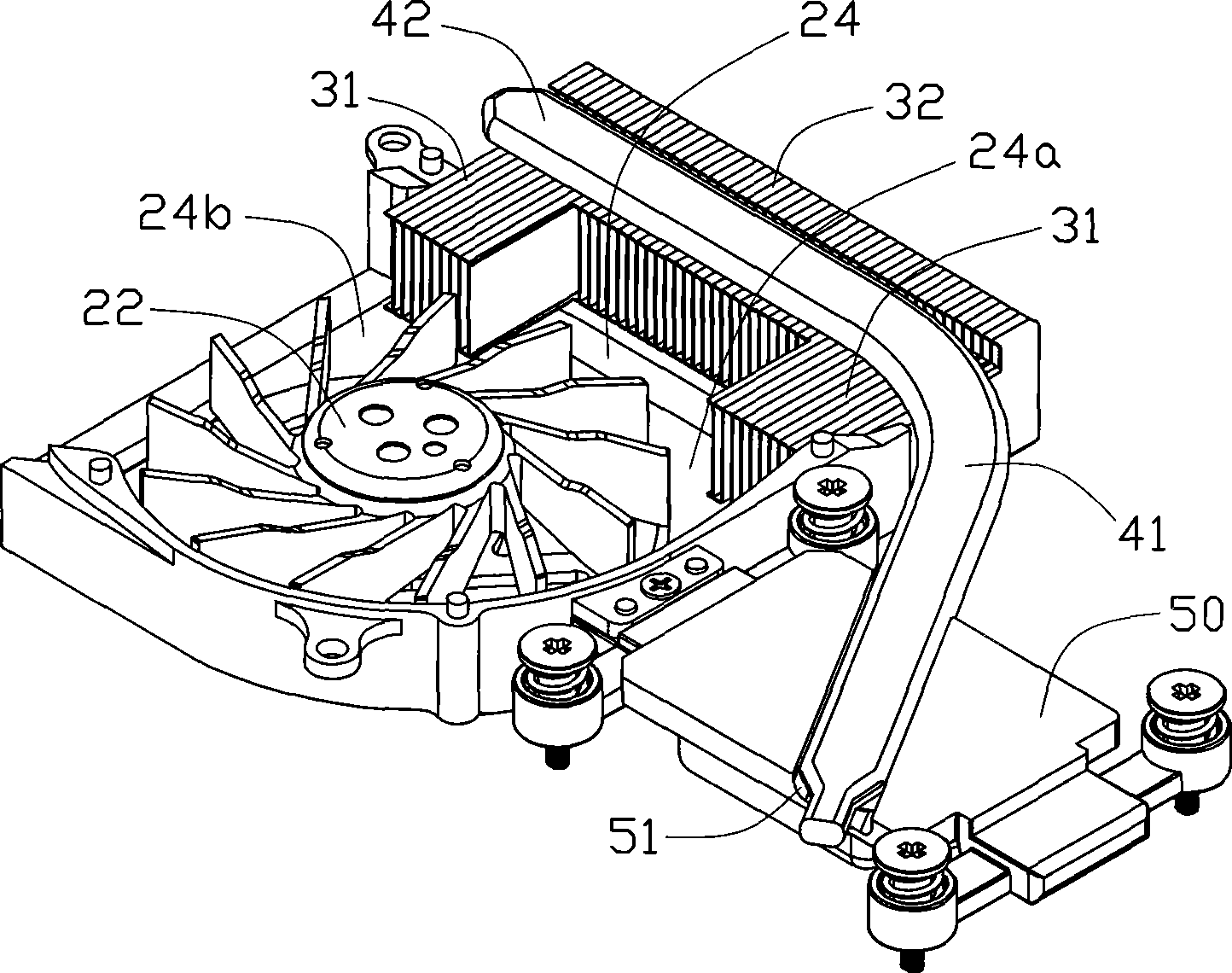

[0013] Figure 1 to Figure 3 Shown is one of the preferred embodiments of the heat dissipation module of the present invention, the heat dissipation module is used to be installed in portable electronic devices such as notebook computers to dissipate heat from the heat-generating electronic components inside it, such as central processing units, graphics card chips, etc. . The cooling module includes a centrifugal fan 20 , a fin set 30 , a heat pipe 40 and a heat collecting block 50 .

[0014] The centrifugal fan 20 includes a casing 21 and a rotor 22 with a plurality of fan blades. The rotor 22 is installed in the casing 21 and can rotate counterclockwise around its axis. The housing 21 includes a base 212 and an upper cover 214 disposed on the base 212. The upper cover 214 is a plate with a circular air inlet 23 in the center for the outside air to enter the centrifugal fan 20. Inside. A rectangular air outlet 24 is defined laterally of the housing 21 , and two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com