Exposure manufacture process, production method of image element structure and semi-modulation type photomask using the same

A manufacturing method and technology of pixel structure, applied in the field of photomask, can solve the problems of poor display quality of liquid crystal displays, large differences in photoresist pattern size, poor etching, etc., so as to improve display quality, simplify the process, and reduce the occurrence of bright spots. the effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

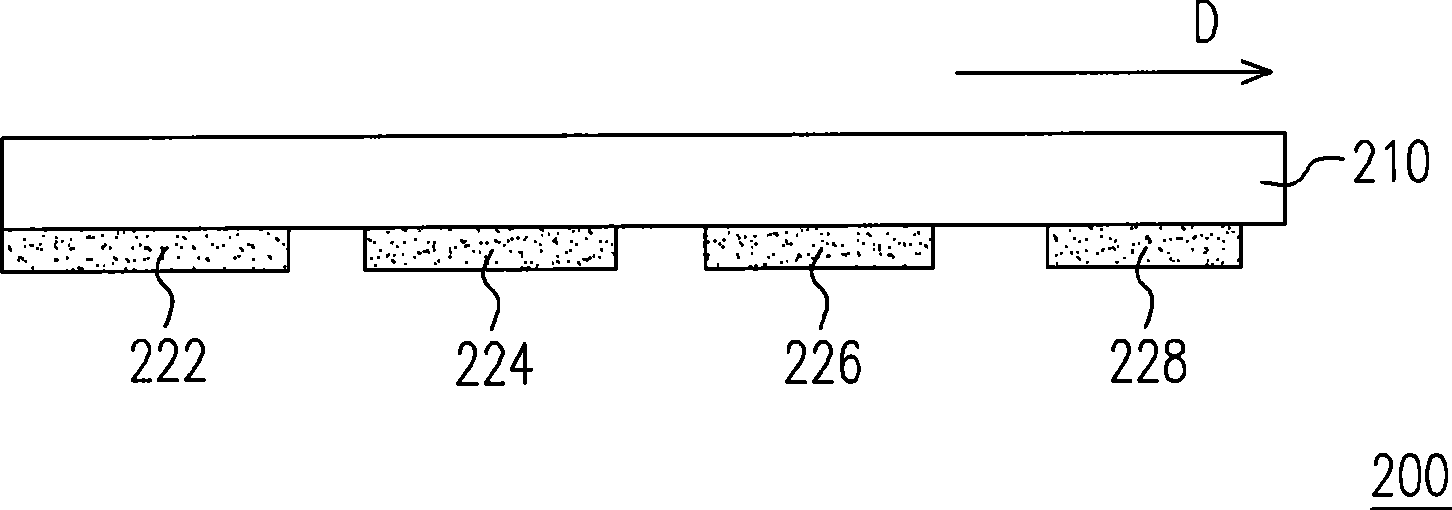

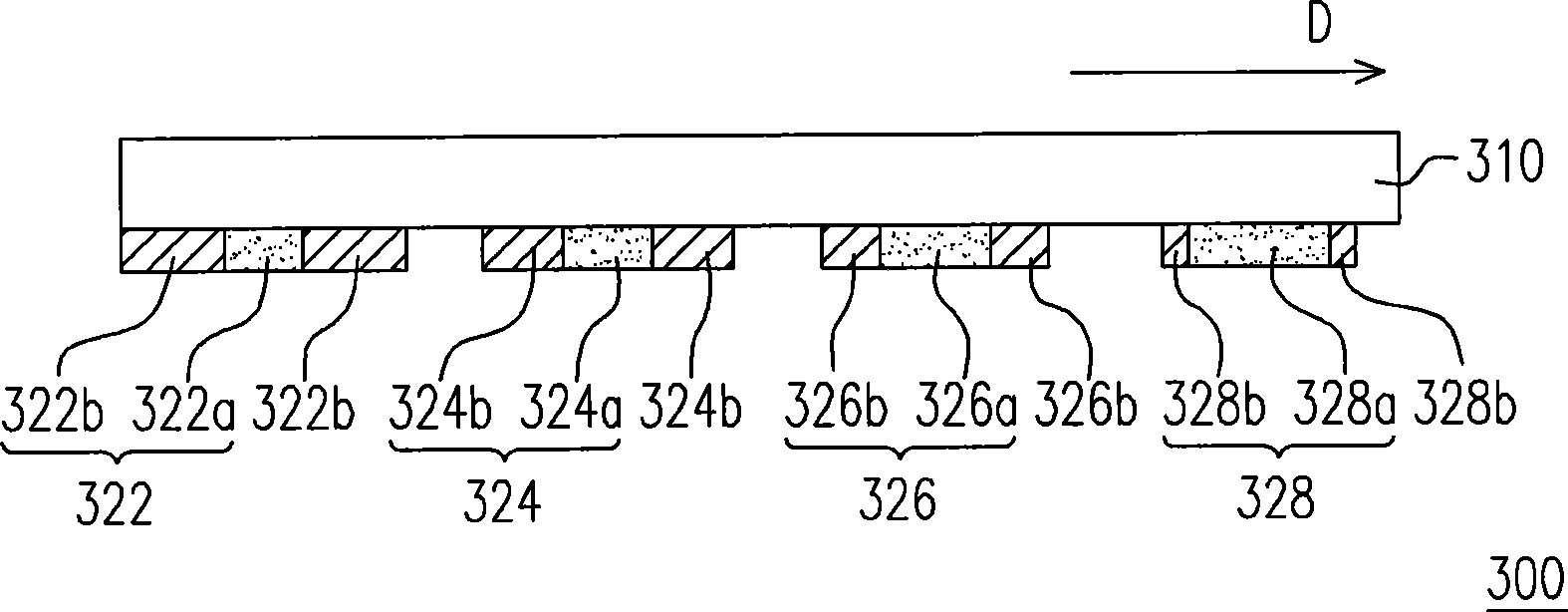

[0064] Figure 2A A schematic diagram of a half-tone photomask according to a preferred embodiment of the present invention is shown. Referring to FIG. 2 , the half-tone photomask 200 is suitable for forming a plurality of photoresist patterns (not shown) with uniform sizes in an exposure process. The half-tone photomask 200 includes a transparent substrate 210 and a plurality of photomask patterns 222 , 224 , 226 , 228 (only four are shown in the figure). These photomask patterns 222, 224, 226, 228 are arranged on the transparent substrate 210 along a set direction D, wherein the size of the photomask patterns 222, 224, 226, 228 is along the set direction D Incremental change.

[0065] Such as Figure 2A As shown, the size of the photomask patterns 222, 224, 226, 228 decreases along the set direction D, however, the size of the photomask patterns 222, 224, 226, 228 can also be set along the direction D direction D and become larger (not shown). It should be noted that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com