Low pressure EGR system

A low-pressure, cooler technology, applied in the charging system, adding non-fuel substances to the fuel, internal combustion piston engines, etc., can solve the problems of heavy burden on the cooling system, insufficient cooling effect, and poor cooling effect of the secondary cooler, etc. Achieve the effect of improving cooling effect and high EGR rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

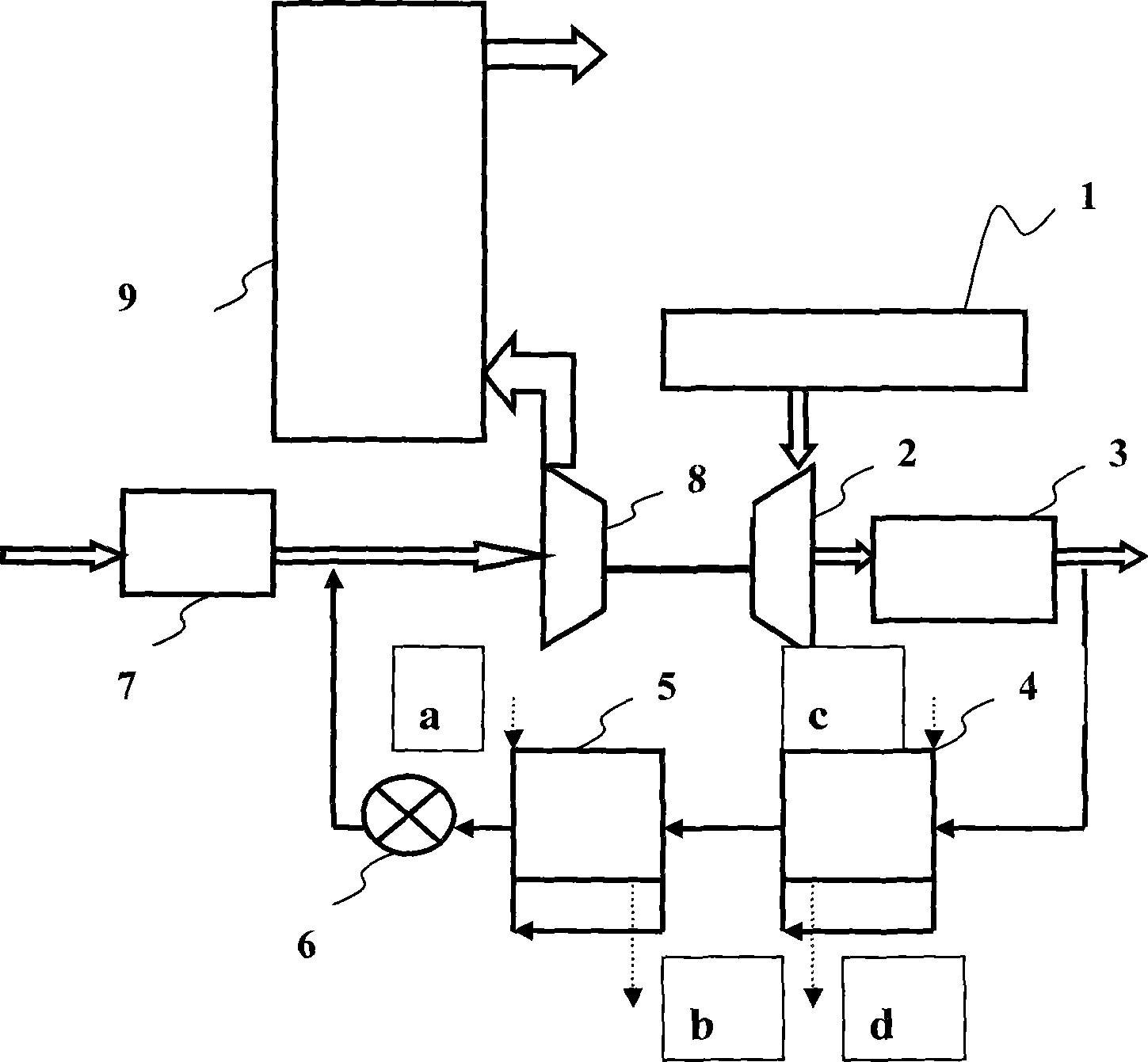

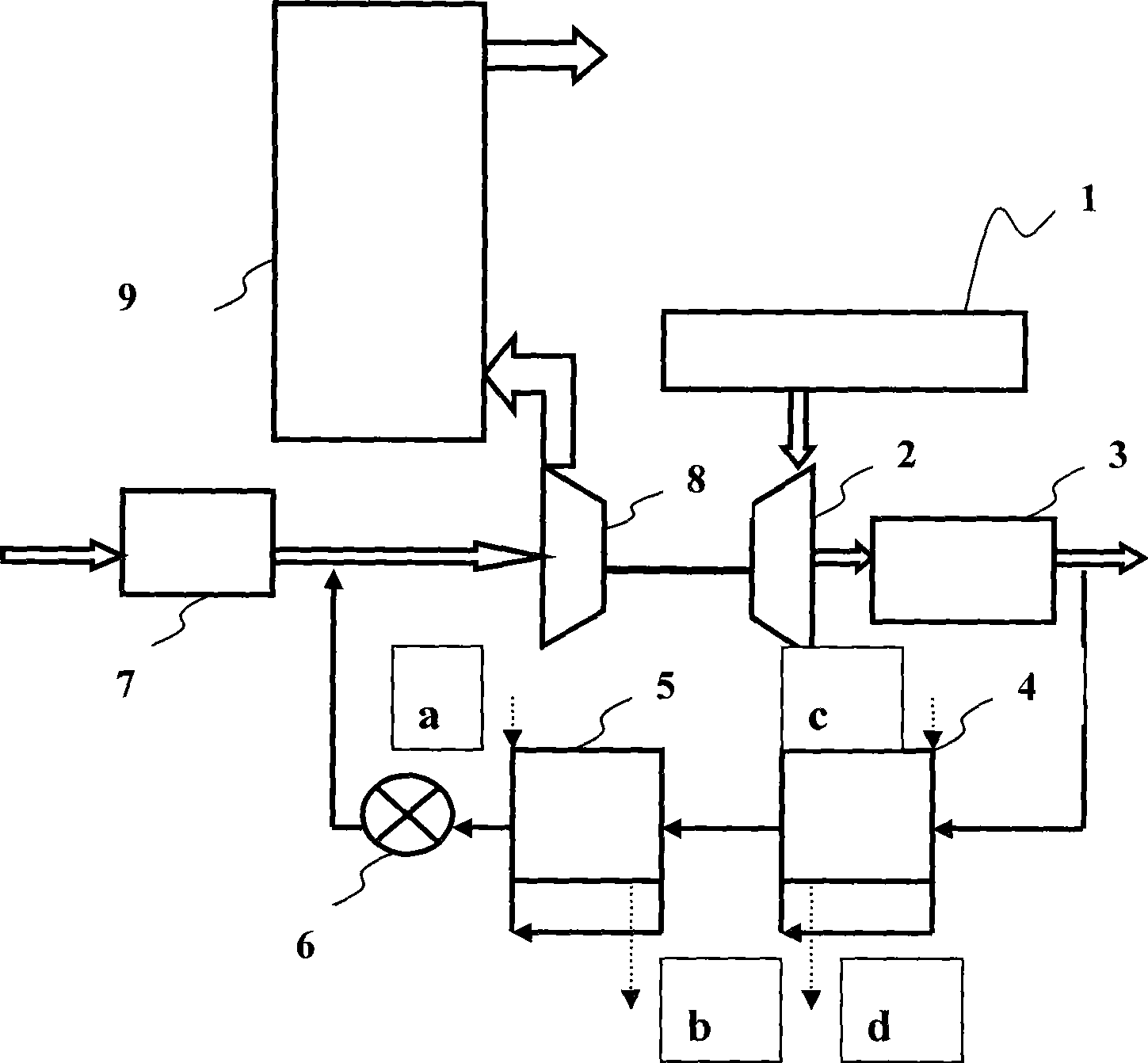

[0022] Such as figure 1 Shown is a schematic diagram of a low-pressure EGR system with an air-conditioning system refrigerant secondary cooling exhaust gas. The exhaust gas flows into the turbocharger turbine 2 through the exhaust manifold 1, then flows out from the particle trap 3, and is discharged into the outside world through the vehicle exhaust pipe and the muffler system. EGR exhaust gas is taken after the particle trap 3, passes through the EGR primary cooler 4 and the EGR secondary cooler 5, the flow is controlled by the EGR control valve 6, and then flows into the engine intake system from the air filter 7 with fresh air Mixed, after being pressurized by the supercharger compressor 8, it flows into the intercooler 9, and then flows into the combustion chamber through the engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com