Floating multi-layer deep water oxygen increasing machine

An aerator, floating technology, applied in water aeration, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of high cost, insufficient oxygen flushing depth, inconvenient maintenance, etc., to achieve the transfer rate And the effect of high utilization rate, high water pressure and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

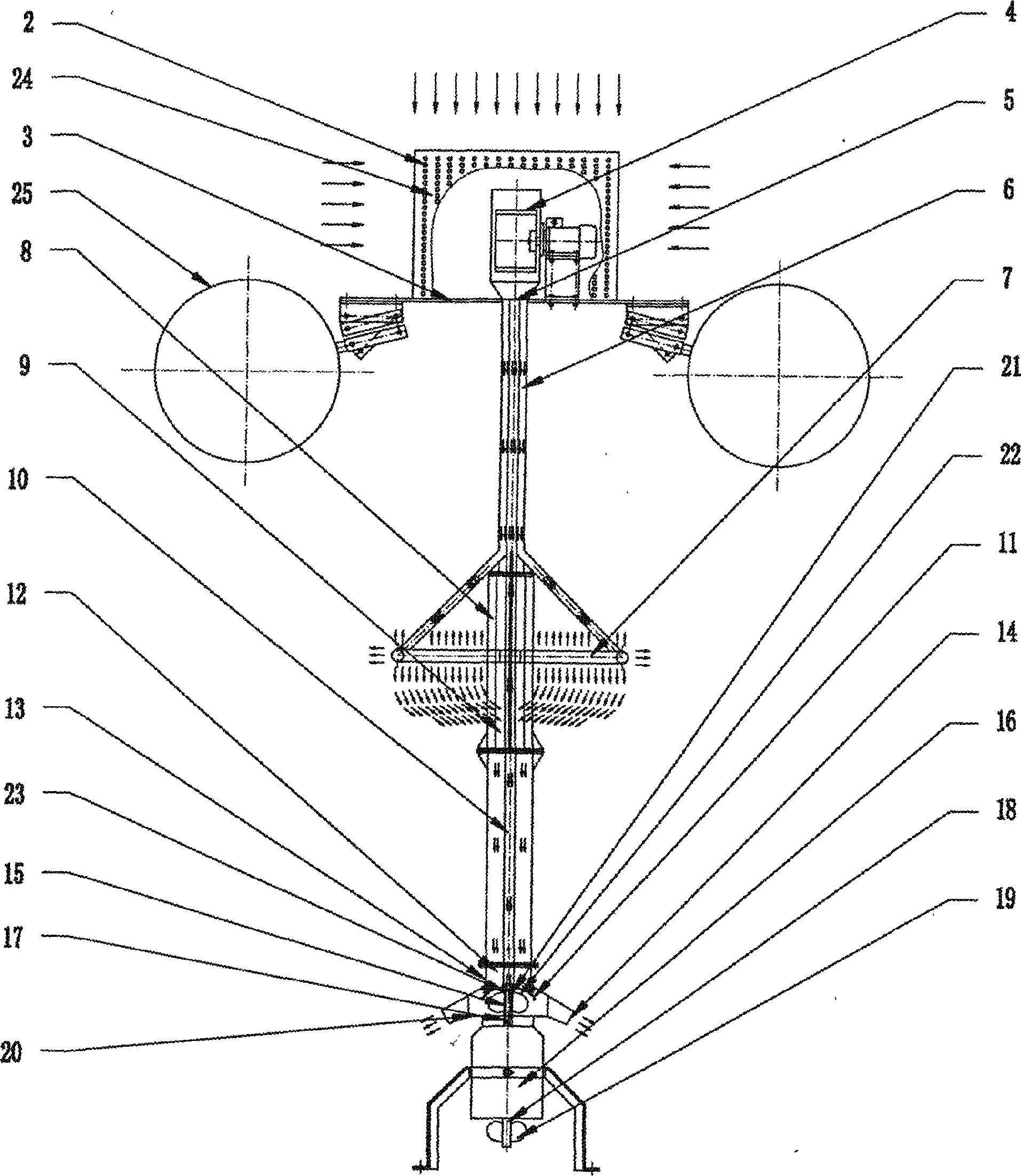

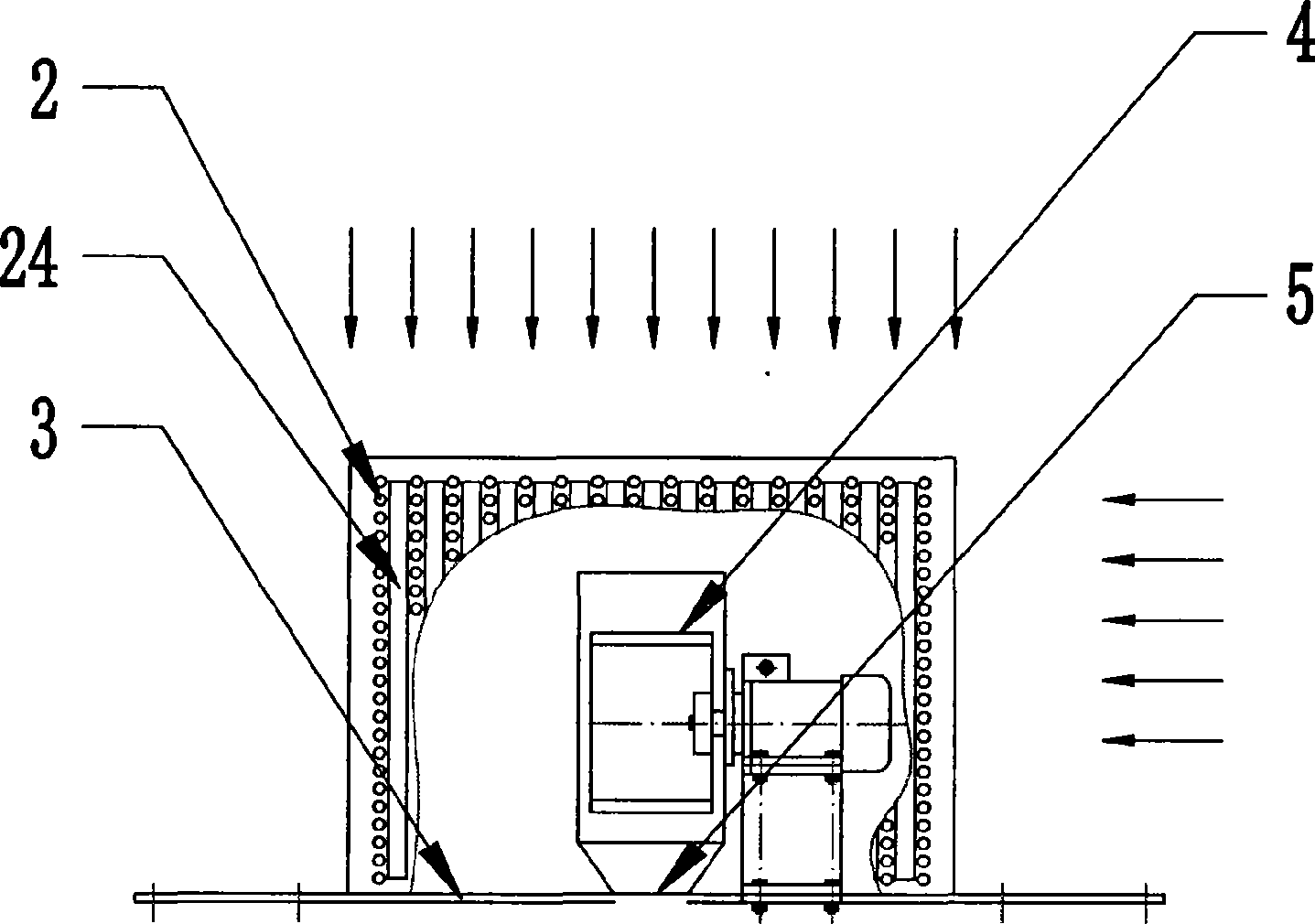

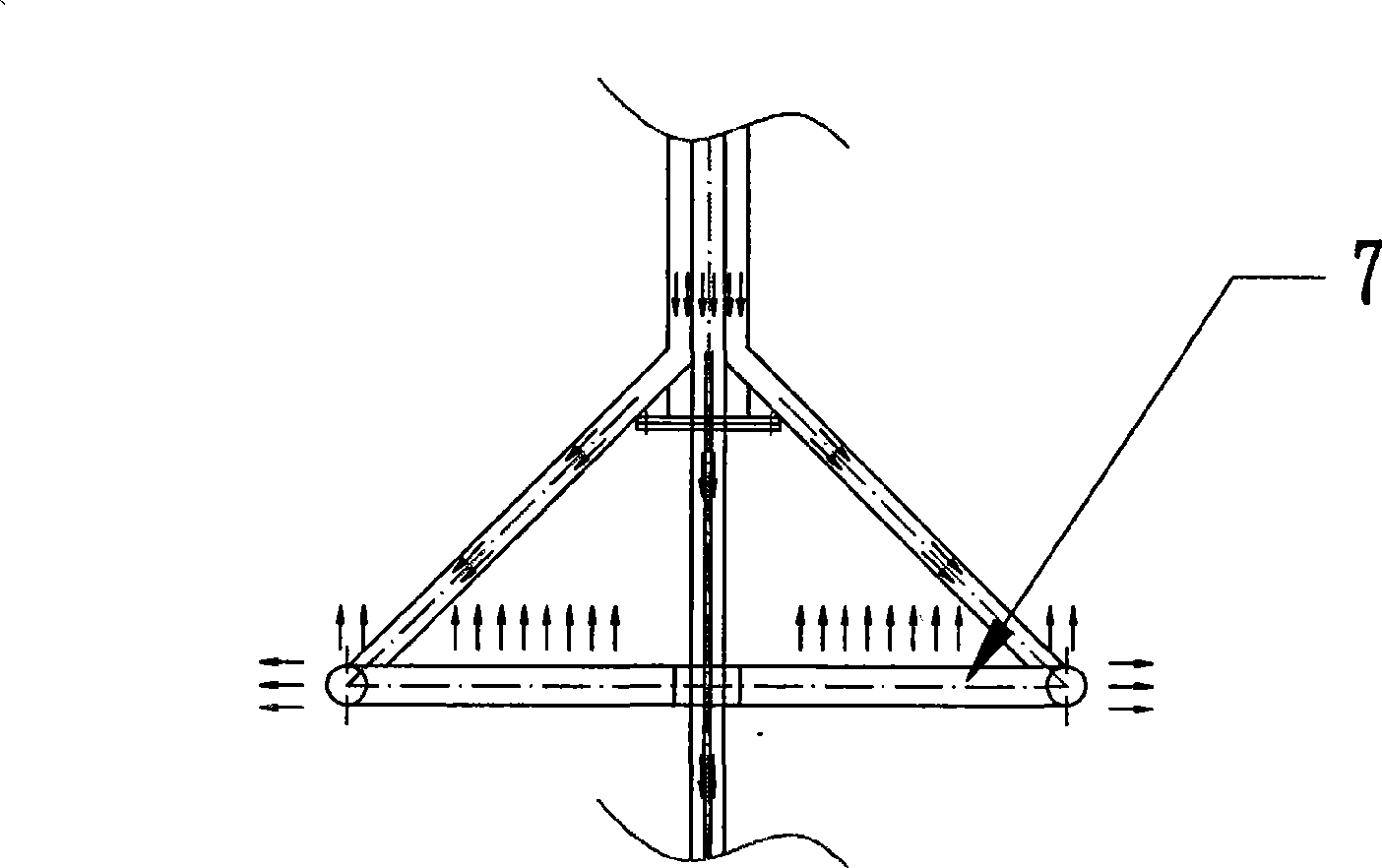

[0019] as attached figure 1 As shown, the present invention is made up of strong magnetic cover, compression blower, middle layer aerator, water-air mixing circulator and submersible motor, and strong magnetic cover 2 is installed on flange 3 plates, and the compression blower that will be installed on the flange plate 4. Completely cover to form a strong magnetic field, open a circular or waist-shaped air inlet on the strong magnetic cover, install permanent magnets 24 between each air port to form a strong magnetic field to cover the compression fan as a whole. The air inlet 5 of the compression fan is connected to the double-layer ventilation pipe, and the outer layer ventilation pipe 6 is connected to the middle layer aerator, and the middle layer aerator is connected to the air outlet of the ventilation pipe. The lower end of the inner layer ventilation pipe 10 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com