Method for degradation of organochloride

An organic chloride, degumming technology, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of toxic intermediates, biological methods are cumbersome and difficult to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A method for degrading organic chlorides, the method is to use an adsorbent to adsorb organic chlorides contained in waste water. In the present invention, the adsorbent is a hollow glass microsphere whose surface is plated with a Fe-Ni alloy layer. The method comprises the steps of:

[0015] 1. Modification of hollow glass microspheres

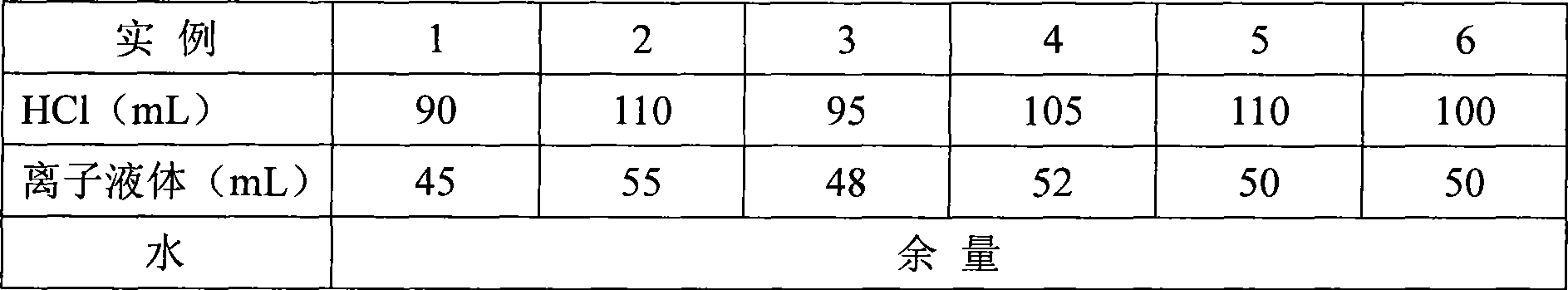

[0016] a. The hollow glass microspheres are pretreated in the order of degreasing cleaning, coarsening, activation, reduction, degumming and post-degumming cleaning;

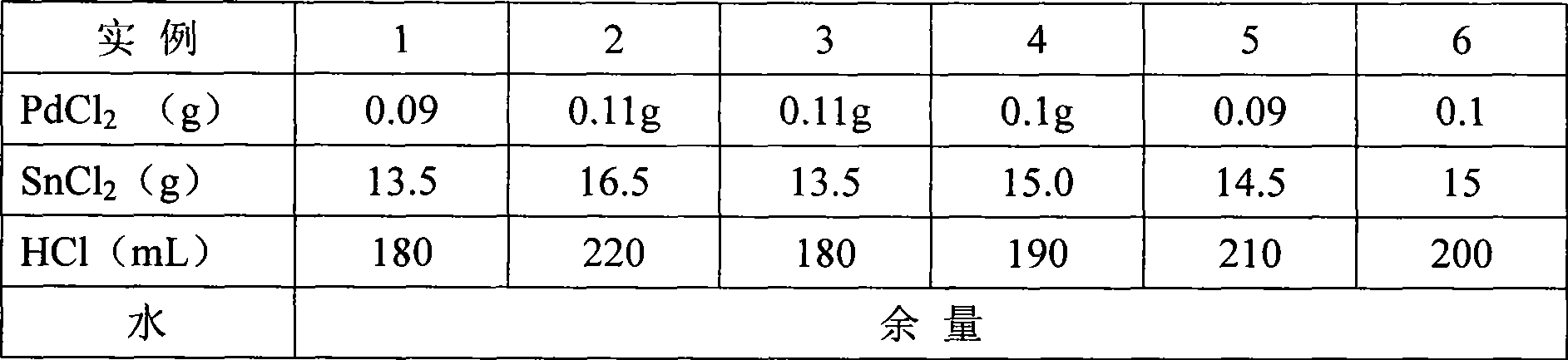

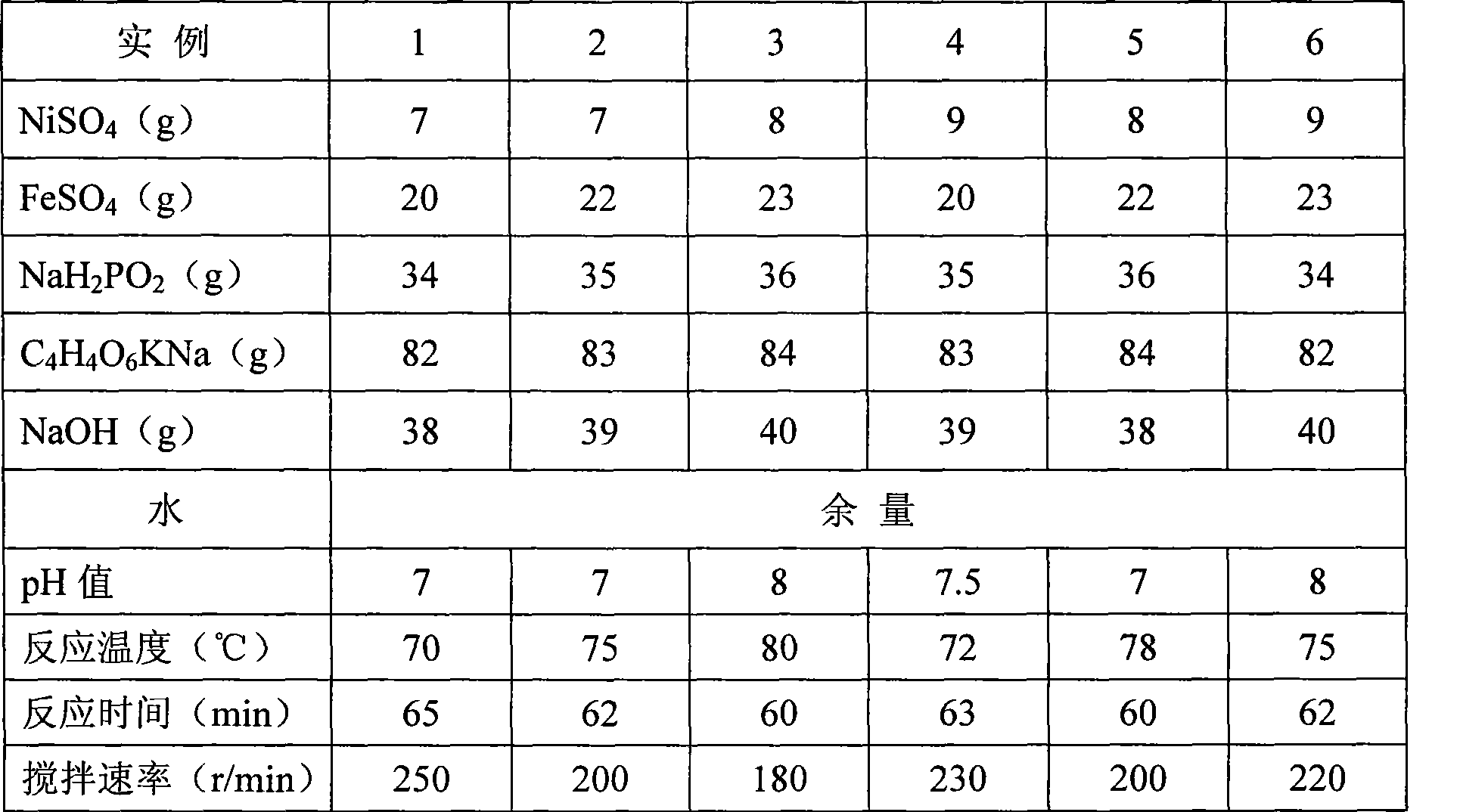

[0017] B, the surface of the hollow glass microspheres cleaned after degumming, plating Fe-Ni alloy layer with liquid phase electroless plating, then, cleaning, drying; In Fe-Ni alloy layer, Fe: Ni=2: 1 ~3:1;

[0018] 2. Degradation of organic chlorides with modified hollow glass microspheres

[0019] c. Fully mix the hollow glass microspheres coated with the Fe-Ni alloy layer with the waste water containing organic chloride according to the mass ratio of 1% to 1.2%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com