Nano- floating type supported photocatalyst, low-temperature preparation method and uses thereof

A photocatalyst, floating technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem that the distribution of TiO2 on the surface of the carrier is not uniform, the floating performance of the photocatalyst is affected, and the porous or hollow structure is damaged. and other problems, to achieve good application prospects, avoid the collapse of the carrier, and avoid the effect of catalyst agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of nano floating type supported photocatalyst, comprises the steps:

[0025] (1) Butyl titanate loading: first dissolve butyl titanate in ethanol to obtain 0.1mol·dm -3 Ethanol solution of butyl titanate; then, after fully mixing 50ml of butyl titanate ethanol solution with 10g of hollow microsphere floating beads, butyl titanate was loaded on the hollow microsphere floating beads by rotary evaporation method, and obtained Hollow microsphere floating beads loaded with butyl titanate.

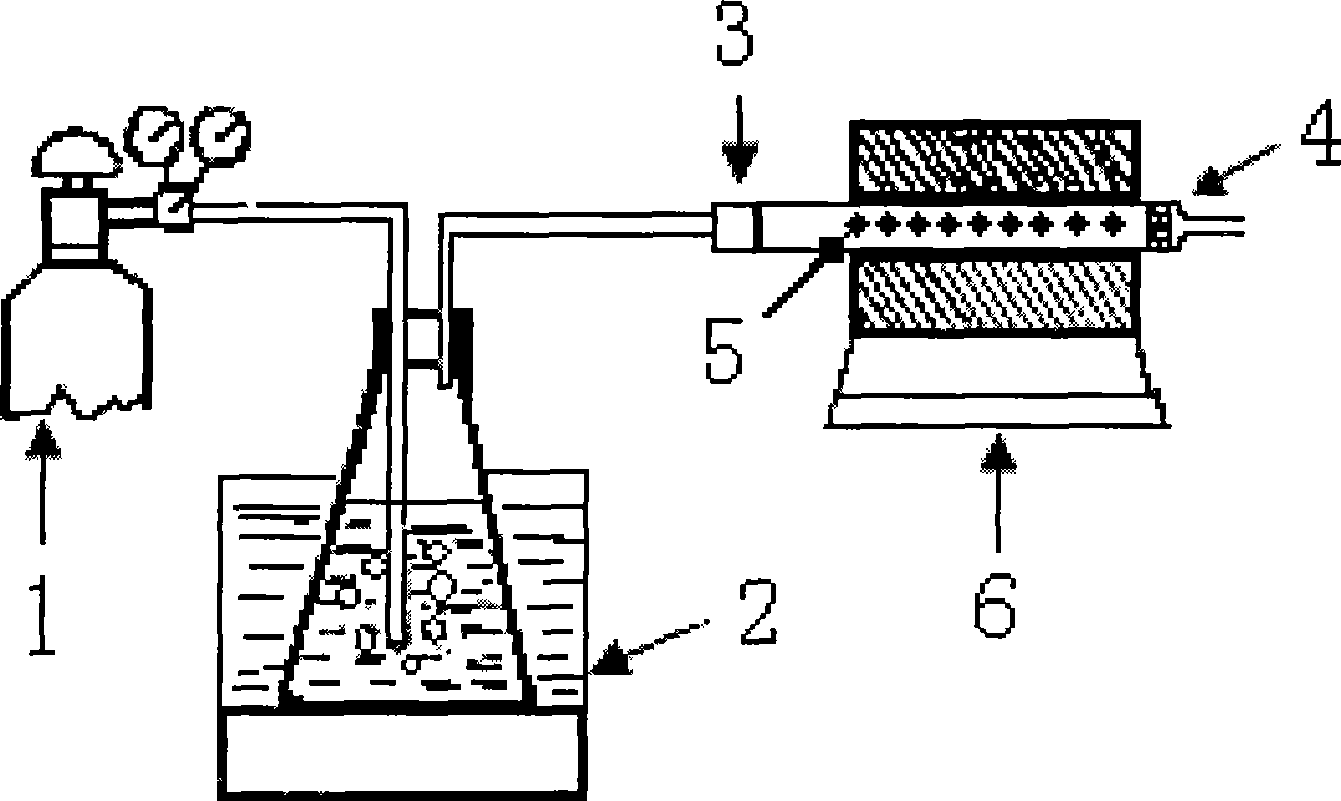

[0026] (2) Heterogeneous hydrolysis reaction: the hollow microsphere beads that have been loaded with butyl titanate are packed in the quartz reaction tube 3 figure 1 The heterogeneous hydrolysis reaction is carried out on the heterogeneous hydrolysis device shown. During the reaction, the air flow rate is 400ml / min, the temperature of the water bath is 60°C, and the hydrolysis reaction temperature is 130°C. After 6 hours of hydrolysis reaction, hydrated TiO ...

Embodiment 2

[0030] A kind of preparation method of nano floating type supported photocatalyst, comprises the steps:

[0031] (1) Butyl titanate loading: first dissolve butyl titanate in ethanol to obtain 0.1mol·dm-3 Ethanol solution of butyl titanate; then, after fully mixing 50ml of butyl titanate ethanol solution with 10g of hollow microsphere floating beads, butyl titanate is loaded on the hollow microsphere floating beads by rotary evaporation method, and obtained Hollow microsphere floating beads loaded with butyl titanate.

[0032] (2) Heterogeneous hydrolysis reaction: put the hollow microsphere floating beads loaded with butyl titanate into the quartz reaction tube figure 1 The heterogeneous hydrolysis reaction is carried out on the heterogeneous hydrolysis device shown. The air flow rate during the reaction is about 400ml / min, the temperature of the water bath is 60°C, and the hydrolysis reaction temperature is 130°C. After 8 hours of hydrolysis reaction, hydrated TiO is formed. ...

Embodiment 3

[0035] A kind of preparation method of nano floating type supported photocatalyst, comprises the steps:

[0036] (1) Butyl titanate loading: first dissolve butyl titanate in ethanol to obtain 0.1mol·dm -3 Ethanol solution of butyl titanate; then, after fully mixing 50ml of butyl titanate ethanol solution with 10g of hollow microsphere floating beads, butyl titanate is loaded on the hollow microsphere floating beads by rotary evaporation method, and obtained Hollow microsphere floating beads loaded with butyl titanate.

[0037] (2) Heterogeneous hydrolysis reaction: put the hollow microsphere floating beads loaded with butyl titanate into the quartz reaction tube figure 1 The heterogeneous hydrolysis reaction is carried out on the heterogeneous hydrolysis device shown. The air flow rate during the reaction is about 400ml / min, the temperature of the water bath is 60°C, and the reaction temperature is 130°C. After 6 hours of hydrolysis reaction, hydrated TiO is formed. 2 / Floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com