Electrical heating volatilization device

A volatilizer and electric heating technology, which is applied in the direction of ohmic resistance heating parts, vaporized substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

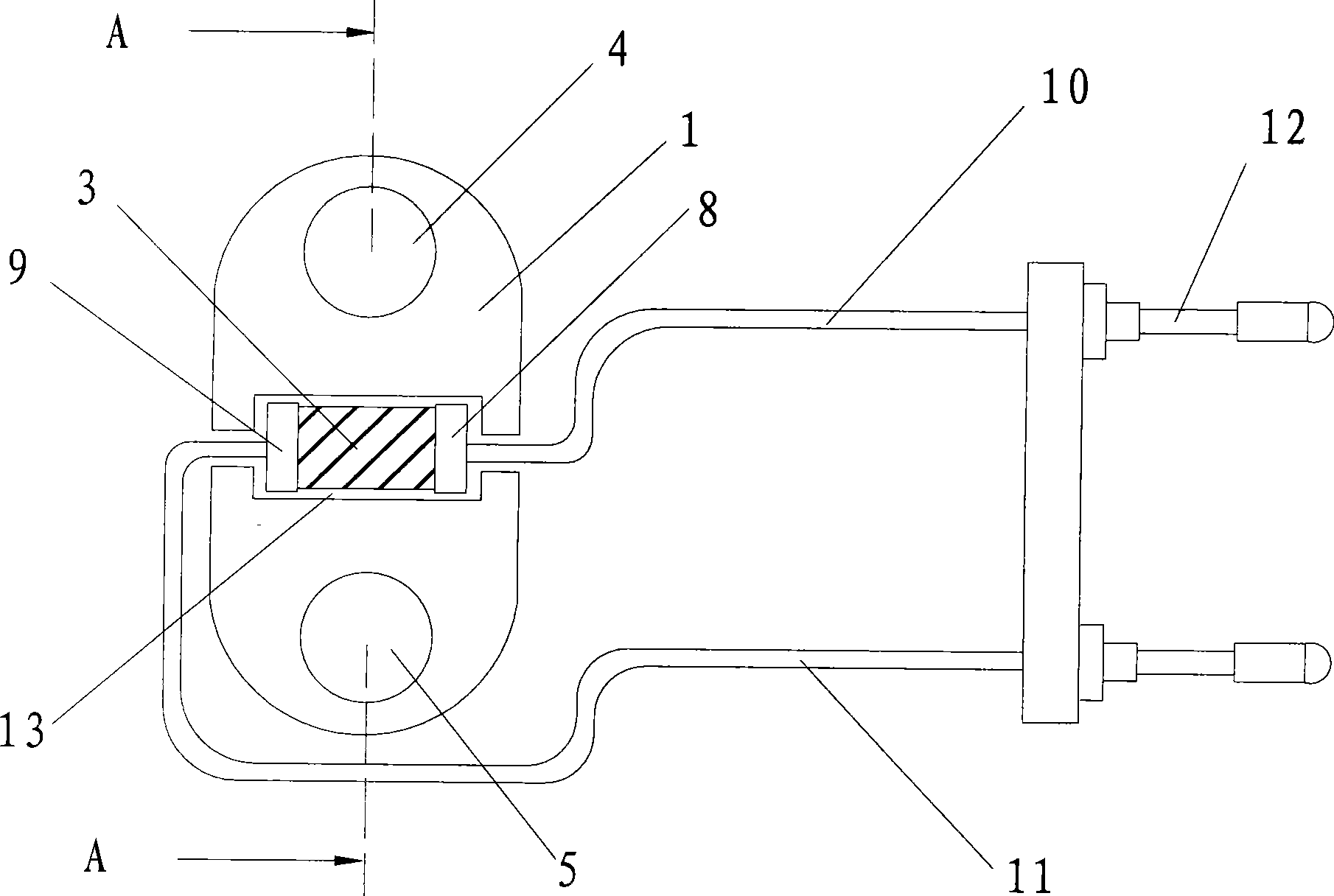

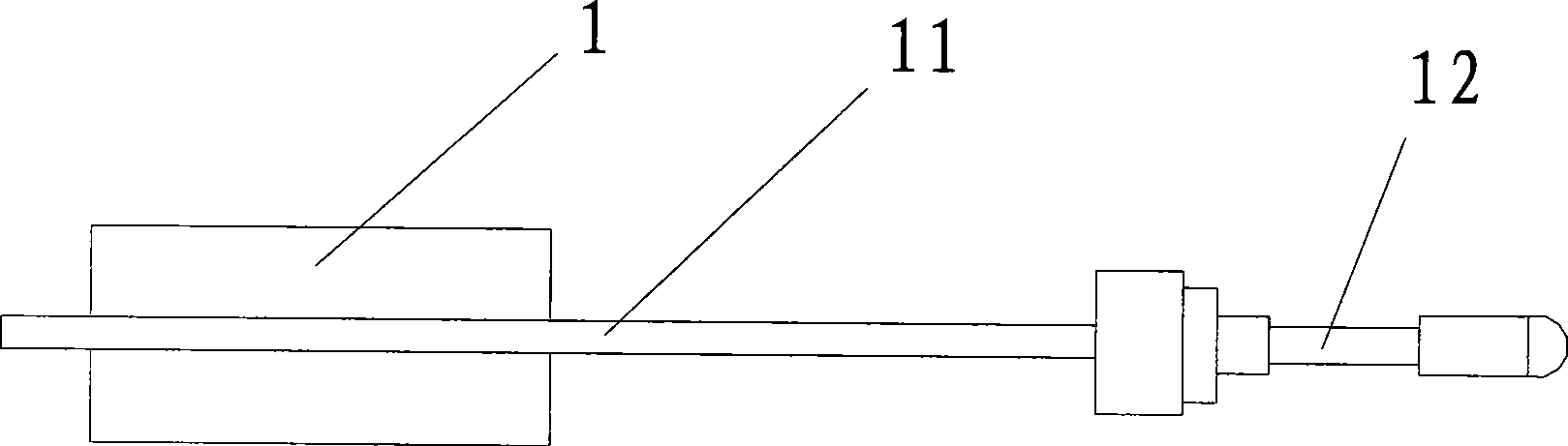

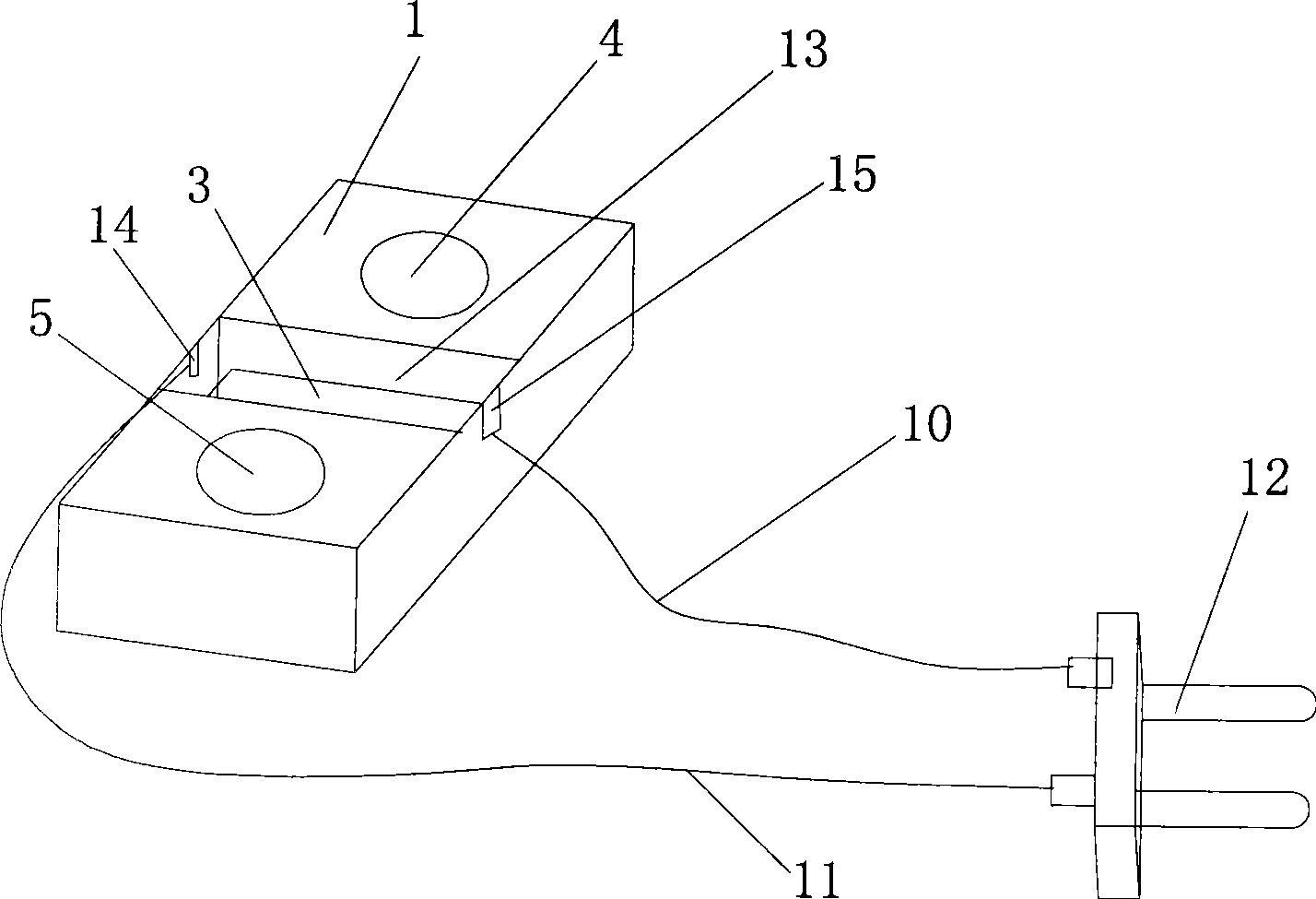

[0032] Embodiment one: if Figure 1 to Figure 3 As shown, the electric heating volatilizer for volatile substances includes a heating device 1, the heating device 1 can be ceramic or plastic, and the resistance element 3 as a heating element is located in the central area of the heating device 1. The two heating core channels 4 , 5 form two through holes in the heating device 1 . The two heating core channels 4 , 5 are identical and placed symmetrically on both sides of the resistance element 3 . The heating device can be oval or rectangular. The resistance element 3 is preferably a fixed resistance. The metal caps 8, 9 are preferably pressed against the two ends of the resistive element 3. The wires 10, 11 are welded and connected to each metal cap, and the wires are preferably copper wires with good conductivity, and the resistance element 3 can also be a PTC resistor.

[0033] Such as Figure 1 to Figure 3 As shown, the resistive element 3 is connected to a plug 12 v...

Embodiment 2

[0036] Embodiment two: if Figure 9 to Figure 11 As shown, the heating device 40 is provided with two liquid-absorbing core channels 42, 43 spaced apart from each other. The liquid-absorbing core channels 42, 43 are located in the middle area of the two resistance elements 44, 45, and the two resistance elements 44, 45 are located in the heating area. At the edges of the device, the resistive elements 44 , 45 have the same design as the resistive element 3 . The resistance elements 44, 45 are preferably of different resistance values.

[0037] Resistive elements 44 , 45 are placed in channels 46 , 47 on the heating device 40 . Electric wires 48, 49 and electric wires 50, 51 are assigned to resistance elements 44, 45, electric wires 10, 11 pass through slits 14, 15 of the groove rear wall, electric wires 48 connected to resistance elements 44 are connected to electric wires 49 connected to resistance elements 45 and manual switches 52 connection, the connection wire 50 of t...

Embodiment 3

[0040] Embodiment three: as Figure 14As shown, the electric heating volatilizer includes three containers 71, 72, 73 that are filled with volatile substances, each container is inserted with a liquid-absorbing core 74, 75, 76, and the heating device is provided with three liquid-absorbing cores at a distance Core channels 77, 78, 79, each channel 77, 78, 79 has a resistance element (not shown in the figure) beside each channel 77, 78, 79, and the design of the resistance element is the same as that of the resistance element 3. The connection mode of electric wire and switch is the same as embodiment two.

[0041] The present invention can also be implemented in the following manner. Each channel of the liquid-absorbing core is used by multiple heating elements, and each heating element has different heating capabilities. Different heating elements can be opened separately according to needs to obtain different evaporation rates, or Turn on all heating elements at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com