Lamp holder and manufacturing method therefor

A manufacturing method and technology of lamp caps, which are applied in the manufacture of discharge tubes/lamps, cold cathodes, and electrode systems, etc., can solve problems such as loosening of pins and shells, potential safety hazards, and pin shedding, so as to avoid loosening and falling off, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

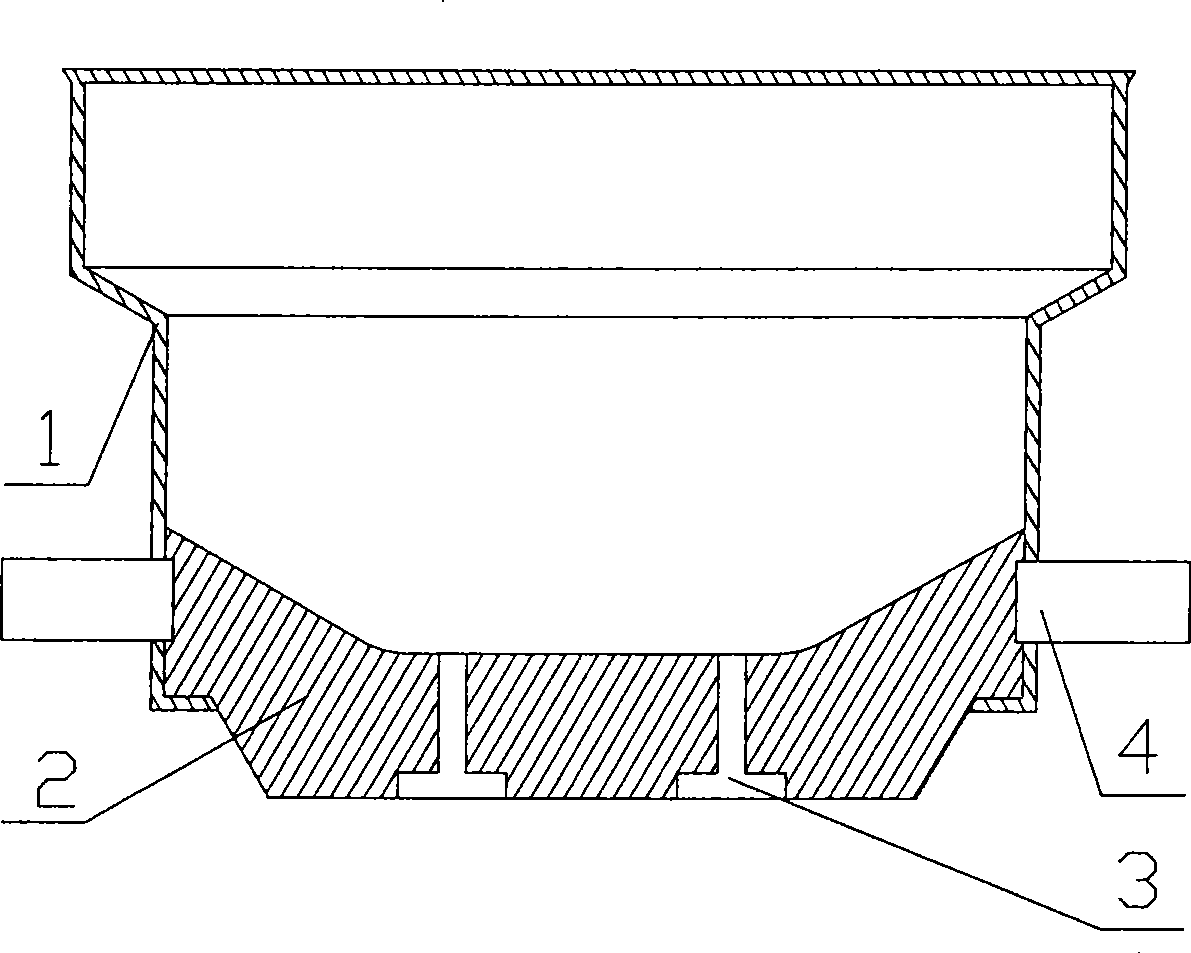

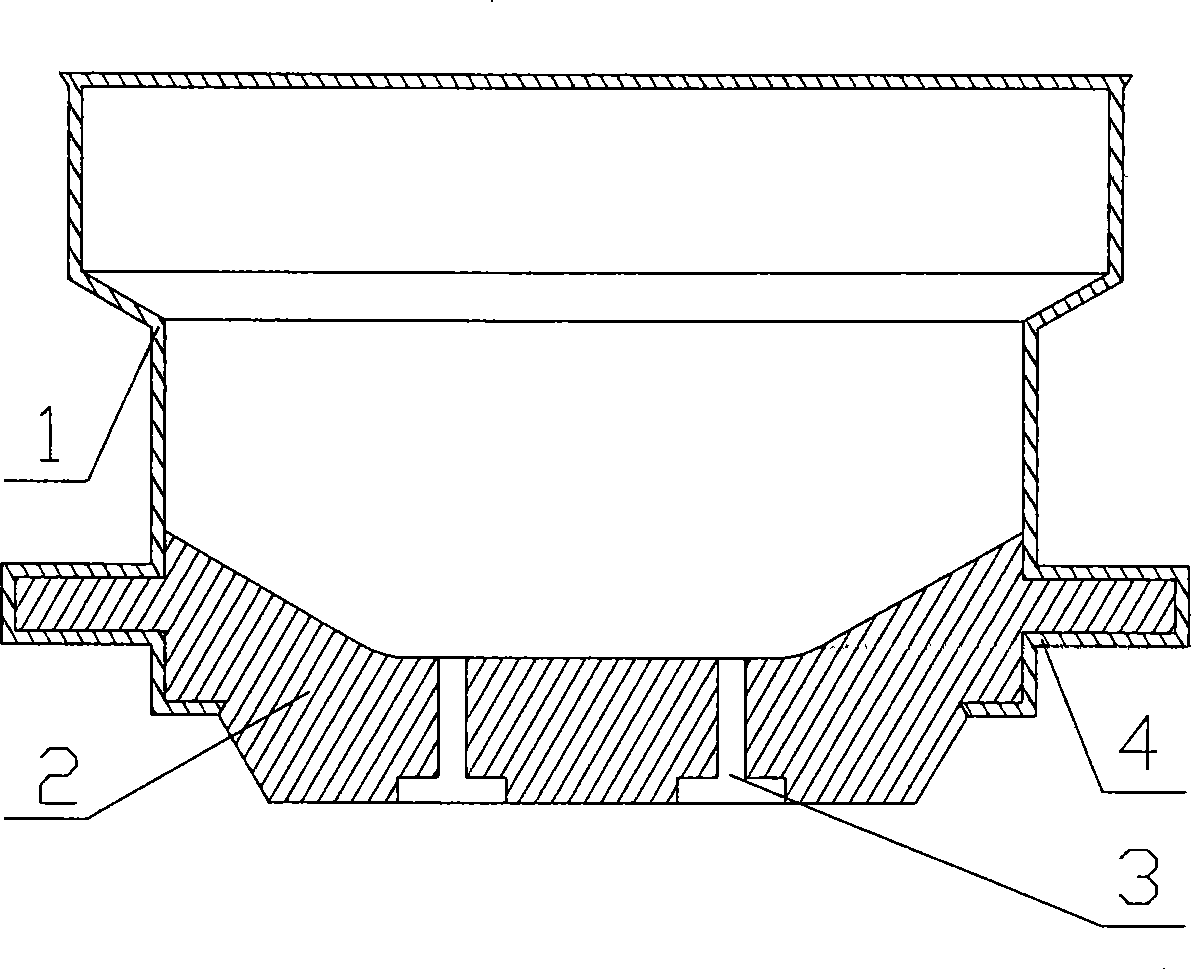

[0013] Such as figure 2 As shown, it is an embodiment of a lamp head of the present invention, which includes a housing 1, and the pin 4 on the housing is a cylindrical cavity protruding outward, with a diameter of 2 mm and a protrusion height of 2.3 mm, which is integral with the housing itself Stamping structure. The shell is a cylindrical cavity with one end open, wherein the diameter of the open end of the shell is larger than that of the sealed end. The sealing end of the shell is composed of an electric contact piece 3 and a black glass insulating part 2, and the shell, the electric contact piece and the black glass insulating part are poured into one body. The thickness of the black glass insulating part is 3mm higher than that of the pin, and the side wall of the black glass insulating part is poured into the cylindrical cavity of the pin to increase the mechanical strength. There are two electrical contact pieces, which are distributed symmetrically with the center...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com