Bismuth film electrode modified by Nafion and use thereof

An electrode and bismuth film technology, applied in the fields of analytical chemistry and heavy metal detection, can solve problems such as blocking electrodes and analytical errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

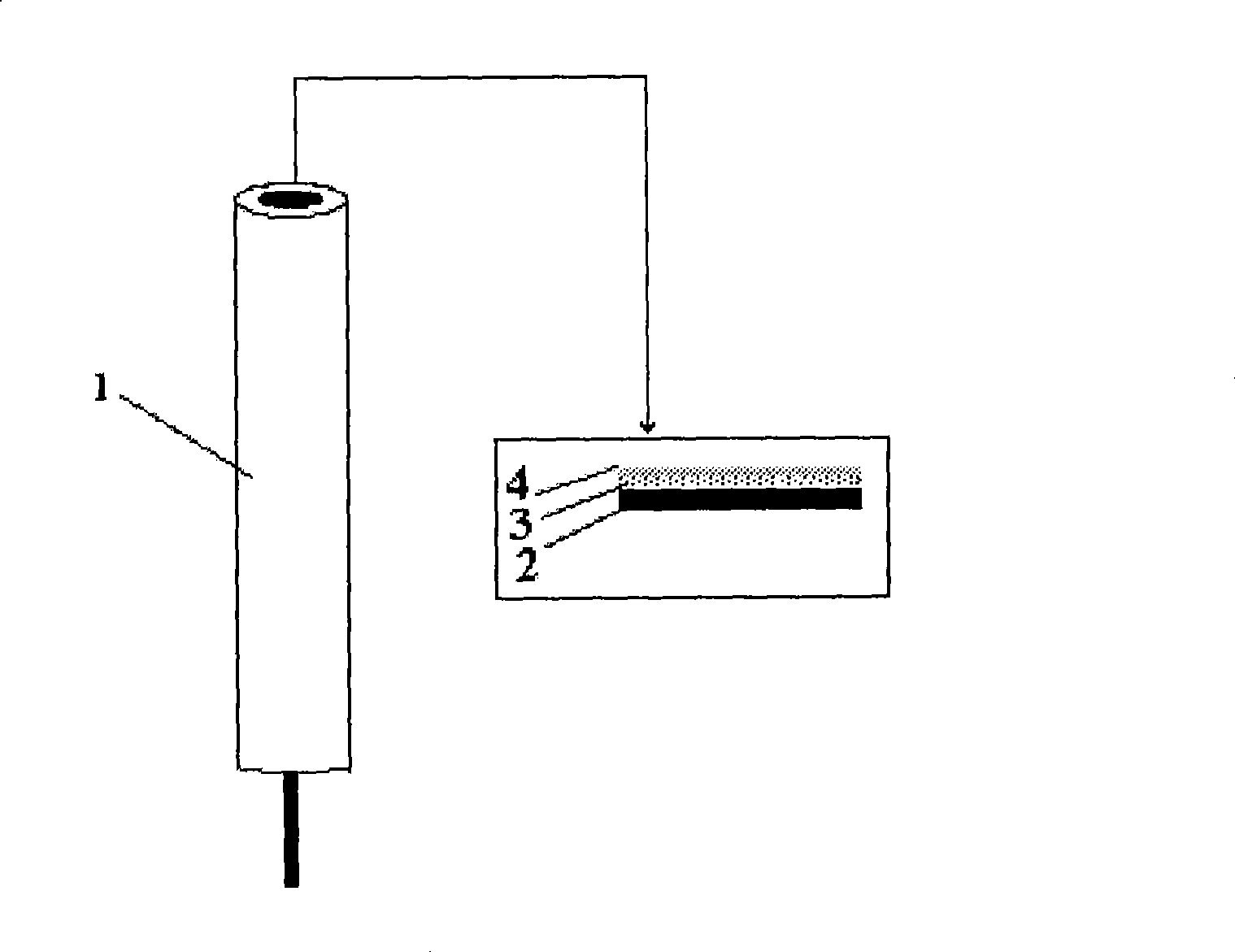

[0083] The present invention also provides a method for preparing the modified electrode, the method comprising the steps of:

[0084] (a) Nafion is coated on the surface of base electrode, forms the electrode that surface is covered with Nafion film; With

[0085] (b) Coating bismuth to the electrode whose surface is covered with Nafion film to form the electrode of the present invention.

[0086] The method of coating the Nafion film and the bismuth film on the surface of the electrode is not particularly limited, as long as the method can make the Nafion film and the bismuth film cover the surface of the base electrode stably in turn. For example, said coating is selected from (but not limited to): solution coating, spray coating, electrolytic deposition.

[0087] As a preferred mode of the present invention, in step (a), Nafion is applied to the surface of the base electrode by solution coating; in step (b), bismuth film is applied to the Nafion film by electrolytic depos...

Embodiment 1

[0124] Embodiment 1 Preparation of electrode of the present invention

[0125] 1. Pretreatment of glassy carbon electrodes

[0126] Grinding and polishing the surface of the glassy carbon electrode by conventional grinding and polishing methods, followed by 1mol / L NaOH solution, 1mol / L HNO 3 solution, ethanol and double distilled water sonication. Let dry at room temperature.

[0127] 2.Nafion modification

[0128] Take a 5% Nafion solution (Nafion powder was purchased from DuPont, batch number 274704, and the solvent of the solution is ethanol) diluted with ethanol to a concentration of 1% Nafion, draw 3-10 μl of 1% Nafion solution with a micro-syringe, and drop-coat it on glassy carbon The surface of the electrode was dried for 10 minutes. A Nafion film with a thickness of about 4-5 μm is formed on the surface of the glassy carbon electrode.

[0129] 3. Preparation of electrolyte solution

[0130] 32g CH 3 COONa·3H 2 Dissolve O in an appropriate amount of water, add ...

Embodiment 2

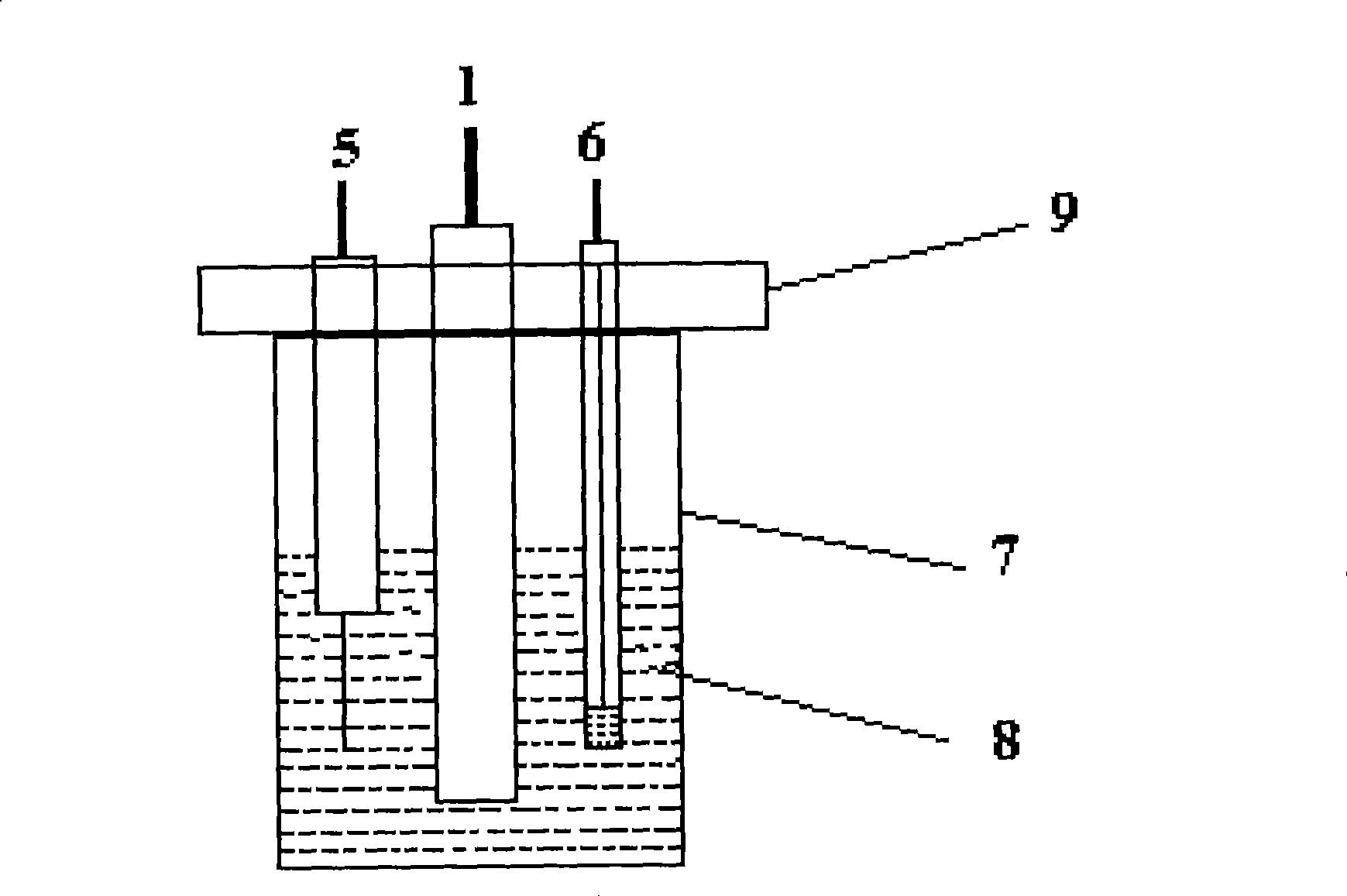

[0136] Example 2 Electrode System

[0137] The electrode prepared in Example 1 is the working electrode; AgCl is plated on the outside of the silver wire to form Ag / AgCl, then Ag / AgCl is placed in the casing, and 3mol / L NaCl is added in the casing to form the electrode As a reference electrode; with platinum wire as and counter electrode.

[0138] The structure of the electrode system is as figure 2 As shown, the electrolytic cell container 7 contains an electrolytic solution 8, the upper end of the container is an electrode support 9, and a working electrode 1, a counter electrode 5 and a reference electrode 6 are distributed on the electrode support 9, and the lower ends of each electrode are immersed in the electrolytic solution. , and the upper ends are respectively connected with the electrochemical workstation.

[0139] Wherein, the casing of the reference electrode 6 contains NaCl solution, and one end of Ag / AgCl is located in the NaCl solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com