Environment-protecting energy-saving gas cooker tray made from stainless steel and metallic plate

A stainless steel plate and gas furnace technology, applied in the direction of the furnace/stove top, can solve the problems of no design preheating and secondary combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

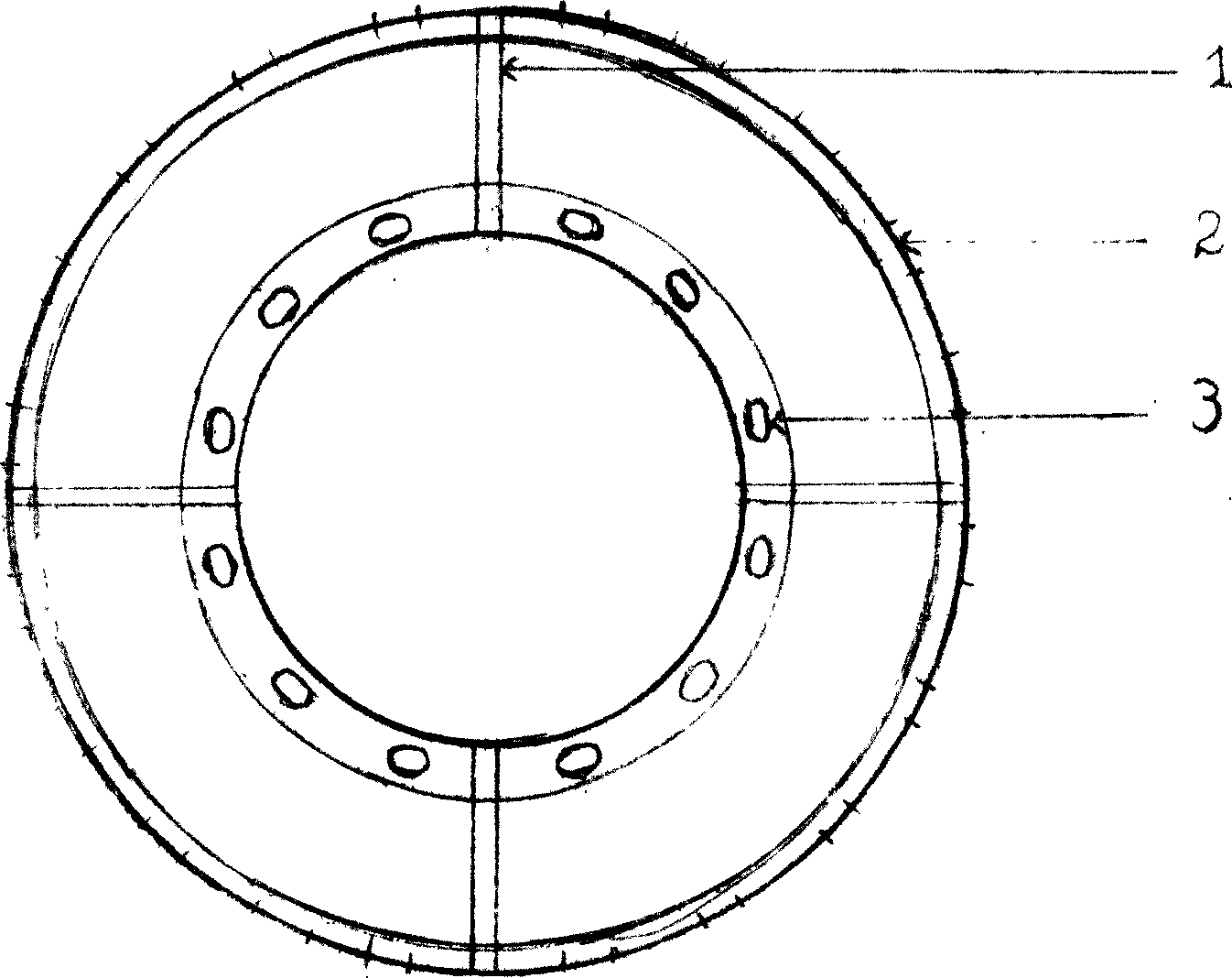

[0021] The technical solution adopted for the technical problem solved by the present invention is: the combustion-supporting air is sucked into the heat preservation room from the upper and outer air intake holes for preheating, and then discharged from the combustion-supporting holes at the inner bottom, and the combustion-supporting air is raised to the limit humidity of air heat energy of 350 degrees After the combustion is carried out, the combustion area forms a good condition and pressure of cold and heat convection, which improves the quality of combustion, greatly reduces the emission of CO, and completely burns the remaining carbon deposits. This design makes full use of three forms of thermal energy transfer, namely: conduction heat, radiation heat, and convection heat. The reason is: the concave gas stove tray blocks the heat conduction to the outside, and the interior Radiation of heat is formed upward. Good cold and heat convection is formed in the surrounding ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com