Suspended type shockproof system

A suspended, elastic component technology, used in springs/shock absorbers, vibration suppression adjustment, mechanical equipment, etc., can solve problems such as large vibration amplitude and acceleration, and unsynchronized optical heads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

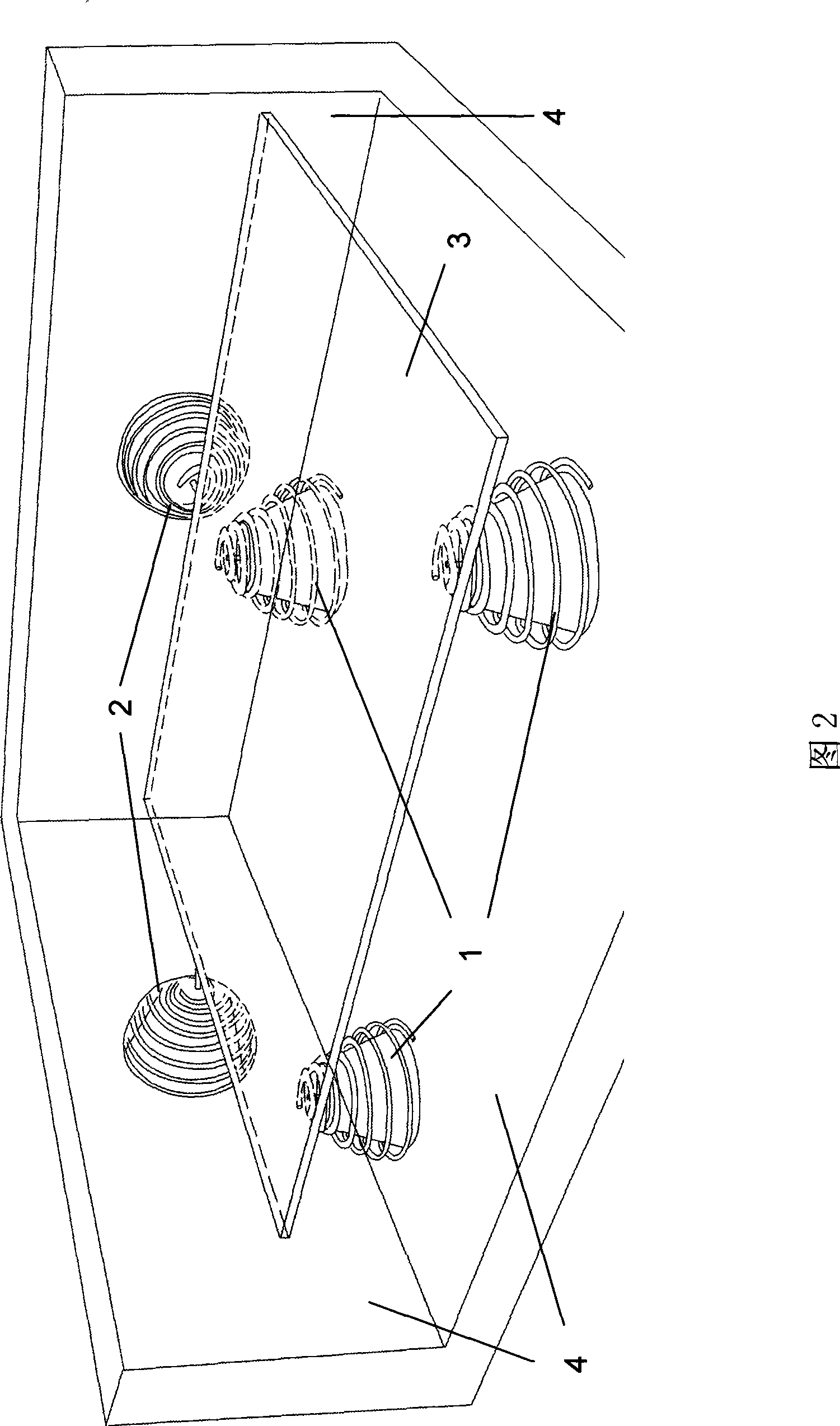

[0022] Refer to figure 1 As shown in FIG. 2, the suspension type anti-vibration system of the present invention includes at least three buffer units 1 and several limiting components 2. The buffer unit 1 includes an elastic member 13 with a hollow inside, a connecting member 11 fixedly connected to the upper end of the elastic member, and a support spring 12 covering the elastic member. The upper end of the support spring is located on the upper end surface of the elastic member and the upper end of the connecting member. Between the end faces. The elastic component 13 in the buffer unit 1 is a silicone rubber sealing sleeve. The elastic component 13 uses silicone rubber as a material and is molded into a hollow silicone rubber sealing sleeve by mold casting. In this embodiment, the elastic component 13 is a tapered elastic part. The connecting component 11 is a stainless steel positioning column. The stainless steel positioning column is machined into a required shape with two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com