C type folded milling-drilling-riveting combined processing center and method of use thereof

A combined processing, milling and drilling technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of backward technical level, high labor intensity, low work efficiency, etc., and achieve good automatic milling and hole processing. , The effect of high work efficiency and large processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

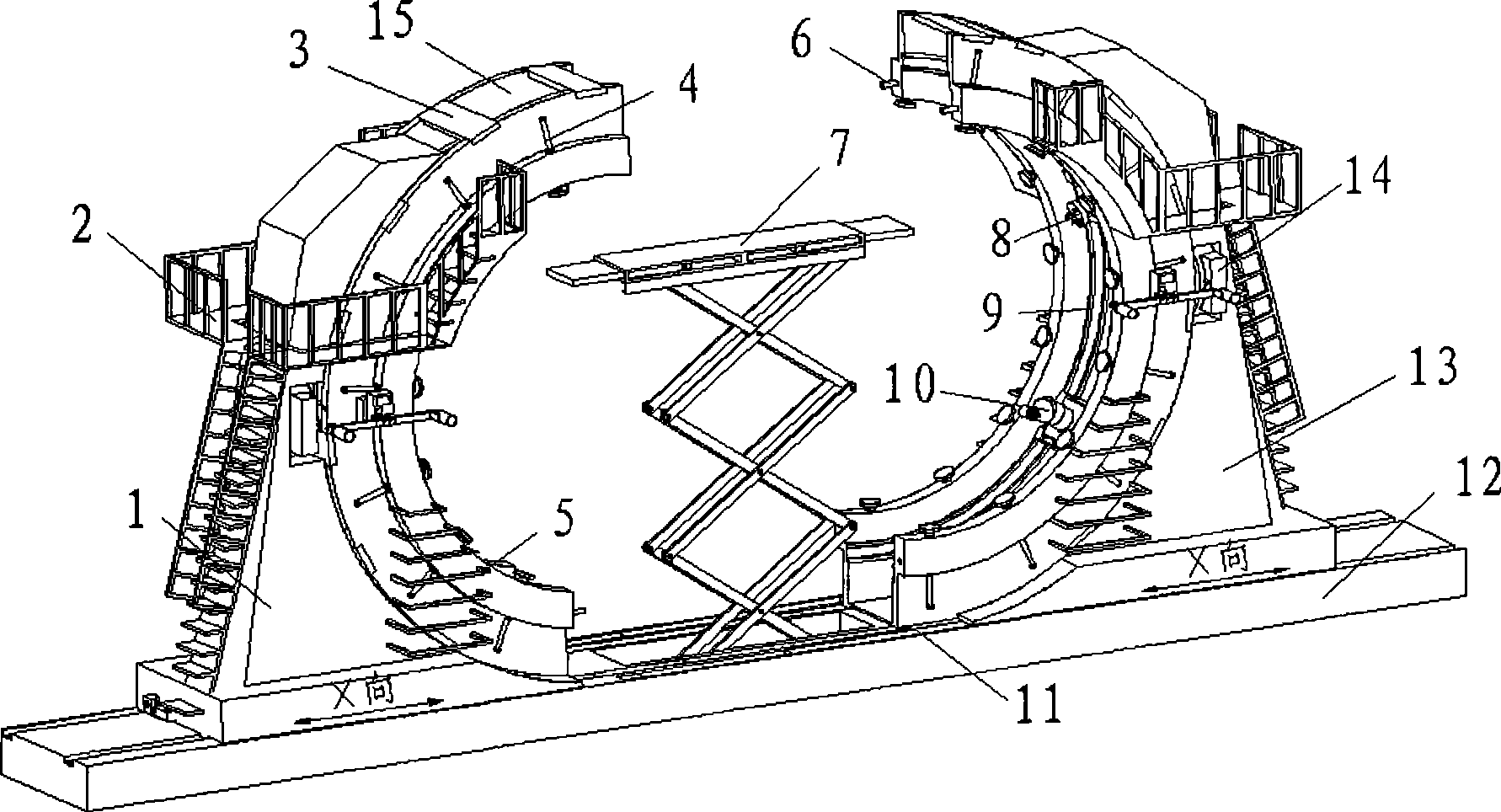

[0030] Such as figure 1 As shown, the C-type combined milling-drilling-riveting machining center includes the left bed of the C-type machine tool 1, the manual operation table 2, the bed connecting rib 3, the pressing device 4, the manual operation ladder 5, and the guide locking device 6. Lifting operation table 7, drilling and riveting device 8, circular guide rail 9, electric spindle power head drilling and milling device 10, guide rail baffle 11, fixed base 12, right bed of C-type machine tool 13, tool changing device 14, semicircle The arc support plate 15, the fixed base 12 are provided with the left bed 1 of the C-type machine tool, the guide rail baffle plate 11, the right bed 13 of the C-type machine tool, and the center of the fixed base 12 is provided with a lifting operation table 7, and the left bed of the C-type machine tool Body 1 and the right bed 13 of the C-type machine tool are respectively provided with two semi-arc support plates 15, and are fixed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com