Life testing device for single-handle double-control water nozzle

A technology of life test device and faucet, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems of inconvenient operation, large impact of the tested object, and easy omission, etc., and achieve the test results. The effect of correcting, reducing and avoiding impact, overcoming destructive damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

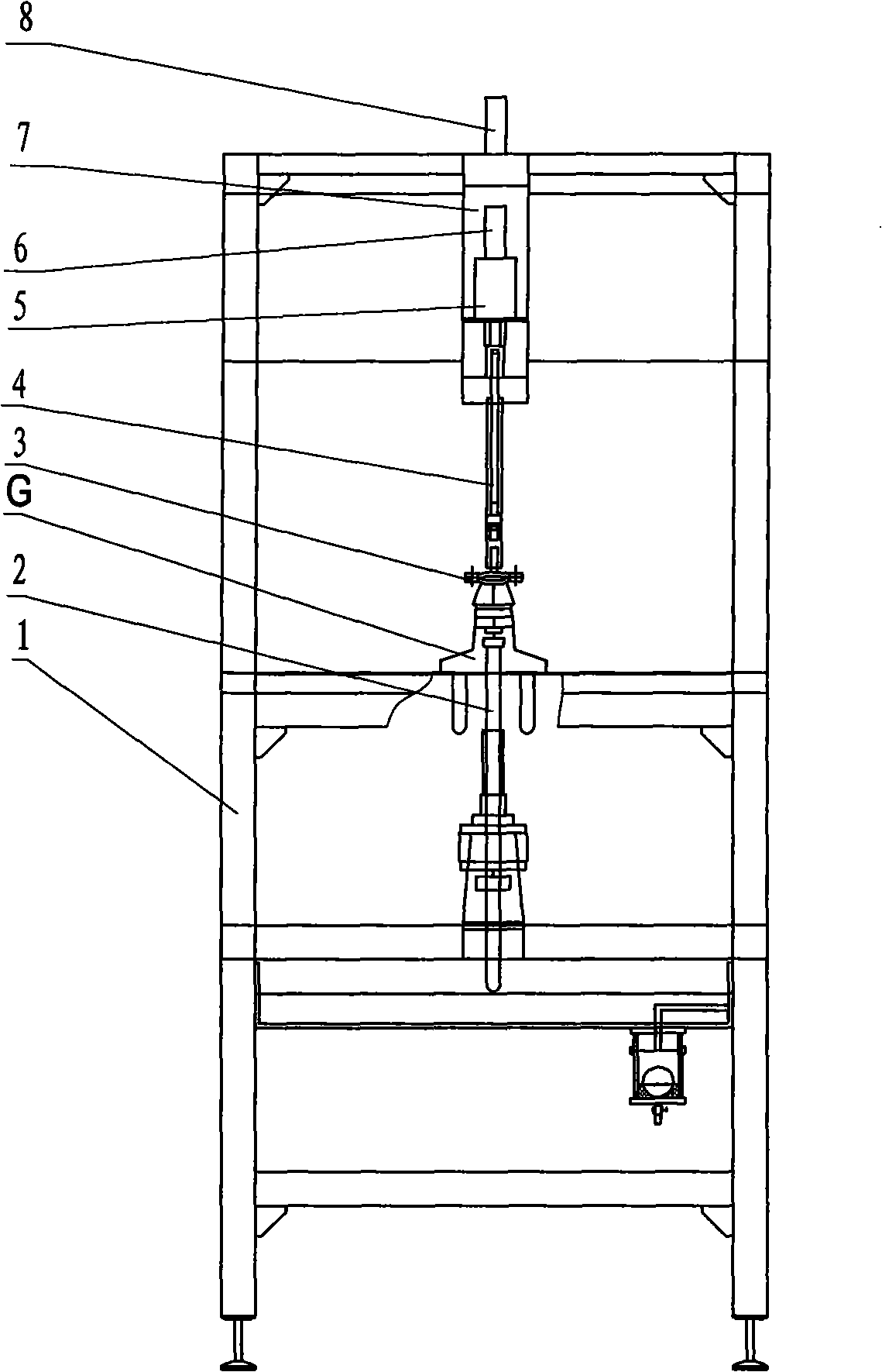

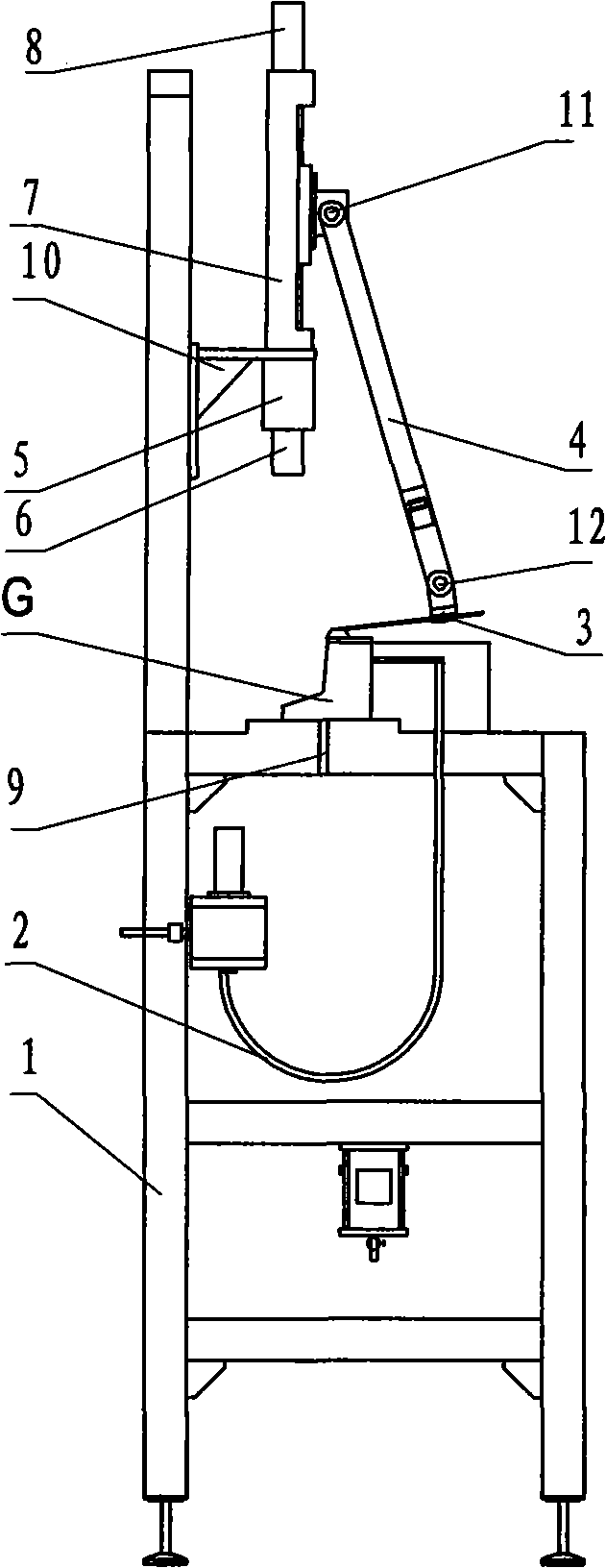

[0026] Such as figure 1 , 3 As shown, a single-handle double-control faucet life test device includes a vertical test bench frame 1, and the tested faucet G is fixed in the middle of the height of the entire frame 1. Such a height is more suitable for installation and testing. The water measuring nozzle G is connected to the cold and hot water inlet pipe 9 . On the top of the frame 1, a rotating disk 5 driven by a small numerical control motor 6 is arranged through the installation angle frame 10. On the rotating disk 5, a lifting assembly driven by a numerical control motor 8 to drive the lead screw pair 7 to move up and down, and a long connecting rod 4 The two ends of each are connected with the nut of the leading screw pair 7 at the upper end and the clamping block 3 at the lower end with the structure of horizontal pivot pins 11 and 12. Start the CNC motor 8 to drive the lead screw pair 7 to move up and down and the rotating disk 5 driven by the small CNC motor 6 to rot...

Embodiment 2

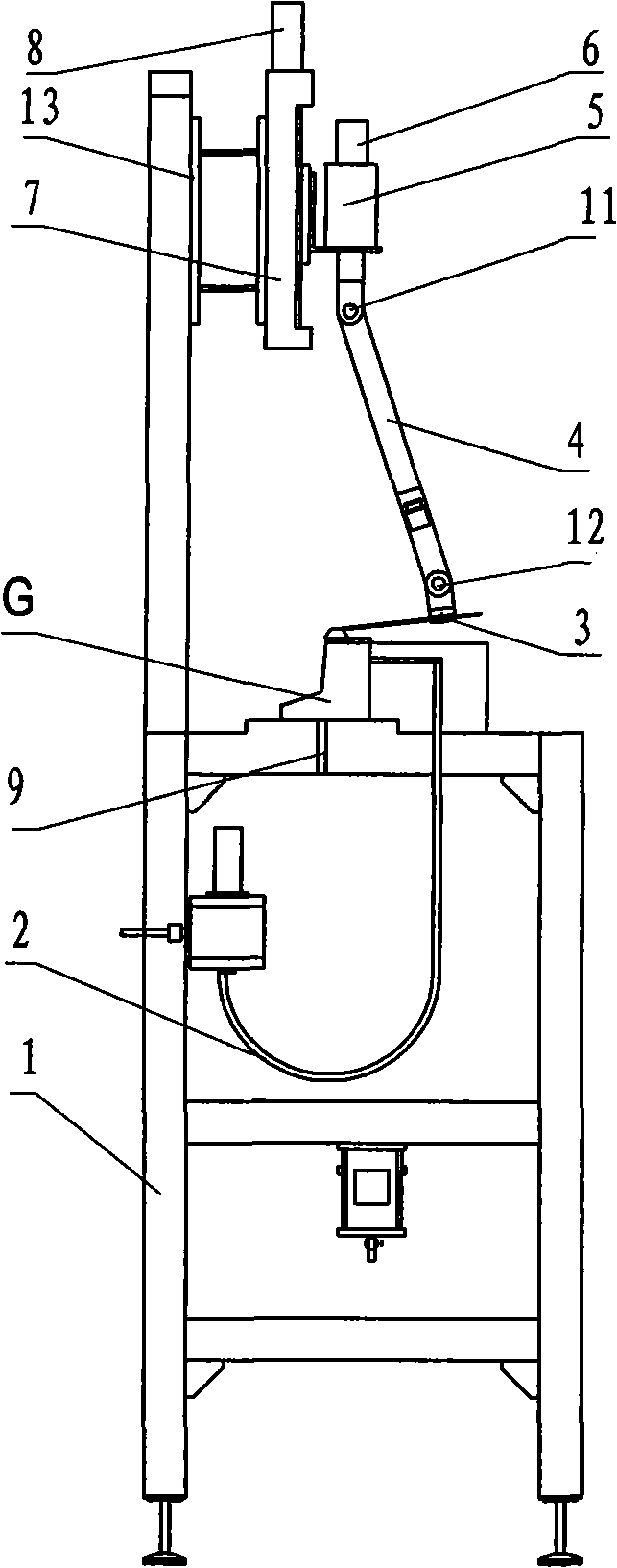

[0028] Such as figure 2 As shown, a single-handle double-control faucet life test device includes a vertical test bench frame 1, the tested faucet G is fixed in the middle of the height of the entire frame 1, and the tested faucet G is connected to hot and cold water. The water inlet pipe 9 fixes the installation frame 13 on the top of the frame 1. On the installation frame 13, the lifting assembly driven by the numerical control motor 8 to drive the lead screw pair 7 to move up and down is arranged. The nut of the lead screw pair is driven by the small numerical control motor 6. The rotating disk 5 is connected with the long connecting rod 4, and the two ends of the long connecting rod 4 are respectively connected with the rotating disk 5 and the clamping block 3 by means of horizontal pivot pins 11 and 12.

[0029]Start the CNC motor 8 to drive the lead screw pair 7 to move up and down and the rotating disk 5 driven by the small CNC motor 6 to rotate. For the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com