Strengthening agent for construction material prepared by carbonizing curing waste

A technology for building materials and carbonization curing, applied in the field of building materials, can solve the problems of shortening production cycle, low strength of carbonized curing building materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

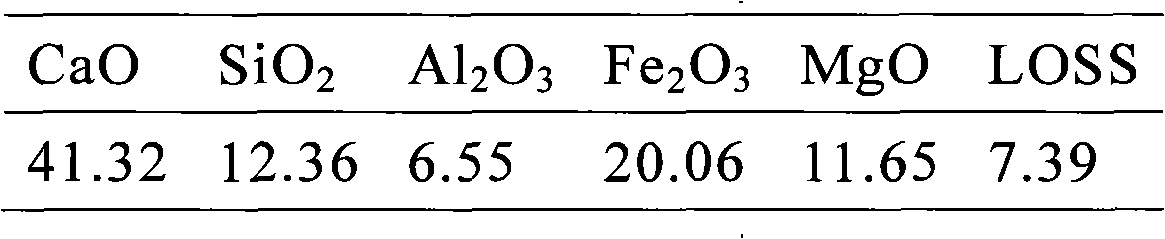

[0019] The steel slag discharged by Jinan Iron and Steel Group is selected as the carbonized material, and its chemical composition is:

[0020]

[0021] Mix the above carbonized materials and water evenly, press them into standard blocks, and use industrial CO 2 gas for conservation, CO 2 The concentration is 20% by weight, and the carbonization curing temperature is 100°C. After two hours of curing, finished bricks are made. After carbonization curing, the weight increase of steel slag bricks absorbs CO 2 About 12%, its strength is about 15MPa.

[0022] Also mix the above steel slag carbonization raw material with slaked lime enhancer and water, adopt the same preparation process, the weight increase of steel slag bricks will absorb CO 2 14%, and its strength is about 20MPa.

[0023] The added amount of the slaked lime reinforcing agent accounts for 5% by weight of the carbonized steel slag raw material, and the content of calcium hydroxide in the slaked lime reinf...

Embodiment 2

[0025] Select the steel slag discharged by Jinan Iron and Steel Group as the carbonized material (same as embodiment 1).

[0026] Mix the above raw materials and water evenly, press them into standard blocks, and use industrial CO 2 gas for conservation, CO 2 The concentration is 20% by weight, and the carbonization curing temperature is 80°C. After two hours of curing, finished bricks are made. After carbonization curing, the weight of carbonized bricks increases to absorb CO 2 8%, and its strength is about 10MPa.

[0027] Also mix the above steel slag carbonization raw materials with waste cement reinforcing agent and water evenly, and adopt the same preparation process, the weight increase of steel slag bricks will absorb CO 2 About 12%, its strength is about 16MPa.

[0028] The added amount of the waste cement reinforcing agent accounts for 10% by weight of the steel slag carbonization raw material, and the content of calcium oxide in the waste cement reinforcing ag...

Embodiment 3

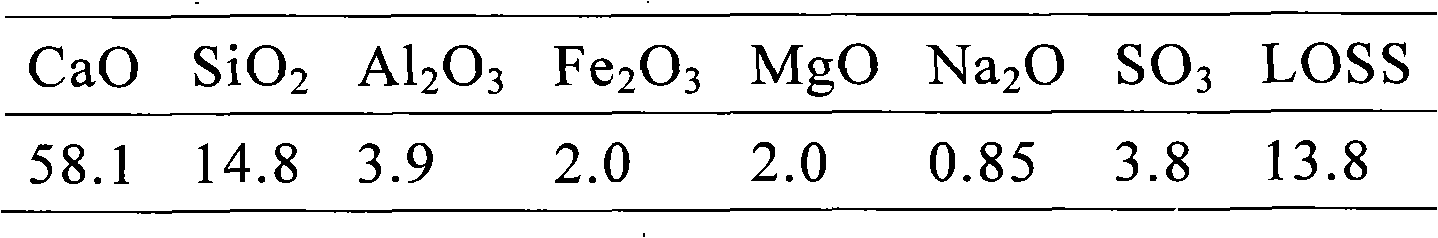

[0030] Select waste cement as carbonized material, its chemical composition and its weight percentage are:

[0031]

[0032] Mix the above raw materials with air-entraining agent and water evenly, press them into air-entrained concrete blocks, and use CO 2 45% wt industrial waste gas is used for curing, the curing gas pressure is 5bar, and the carbonization curing temperature is 150°C. After 3 hours of curing, carbonized aerated concrete blocks are made.

[0033] After carbonation curing, the weight increase of aerated concrete block absorbs CO 2 15%, and its strength is about 4MPa.

[0034] Also mix the above waste cement carbonization raw materials with quicklime enhancer, air-entraining agent and water evenly, and adopt the same preparation process, the weight increase of carbonized air-entrained concrete blocks will absorb CO 2 17%, and its strength is about 5MPa.

[0035] The added amount of the quicklime reinforcing agent accounts for 8% by weight of the waste c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com