Conveyor for sheet-shaped thin plate and method of conveying same

A thin-plate and sheet-like technology, which is applied in the field of conveyors and conveying sheet-like thin plates, can solve the problems of poor adhesion of thick plates, unstable conveying speed, and increased conveying resistance, avoiding vertical overlapping or overlapping, and improving adjacent welding performance. , to maintain the effect of high-quality welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

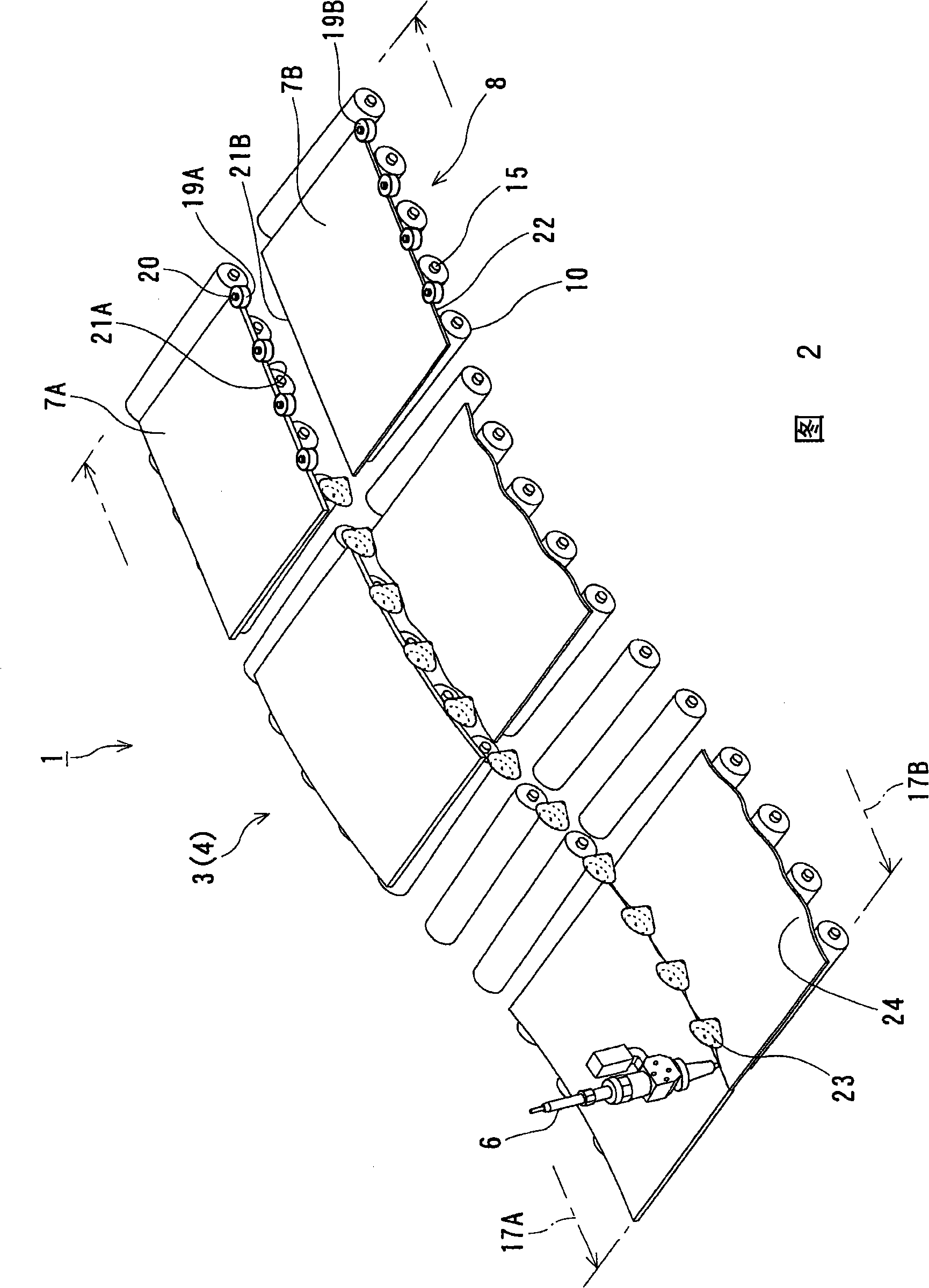

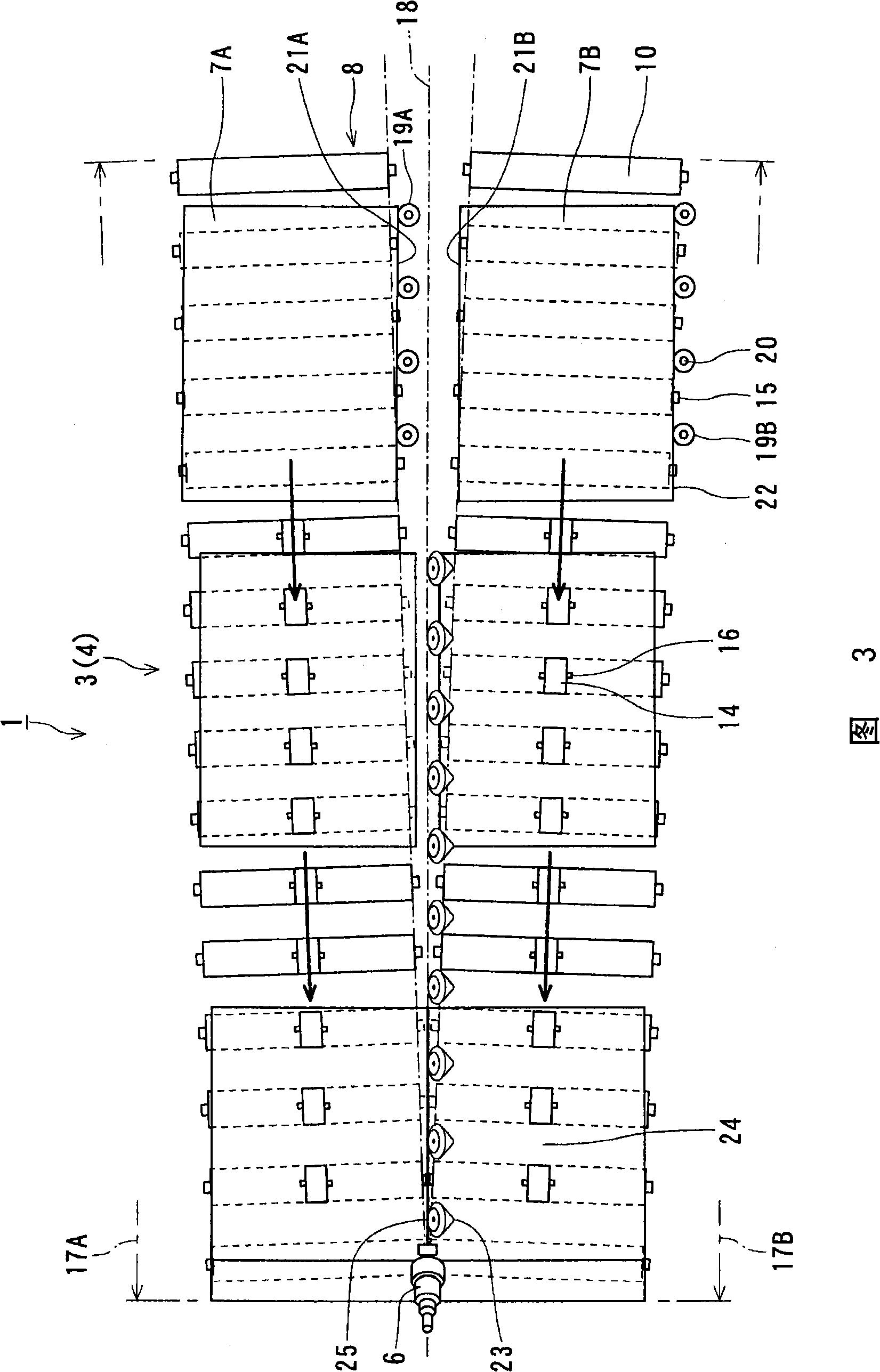

[0049] Hereinafter, preferred embodiments of the present invention will be explained with reference to the accompanying drawings. Furthermore, it is to be noted that the terms "upper", "lower", "right side", "left side" and similar terms are used in the states shown therein with reference to the drawings or within the normal operating state of the device.

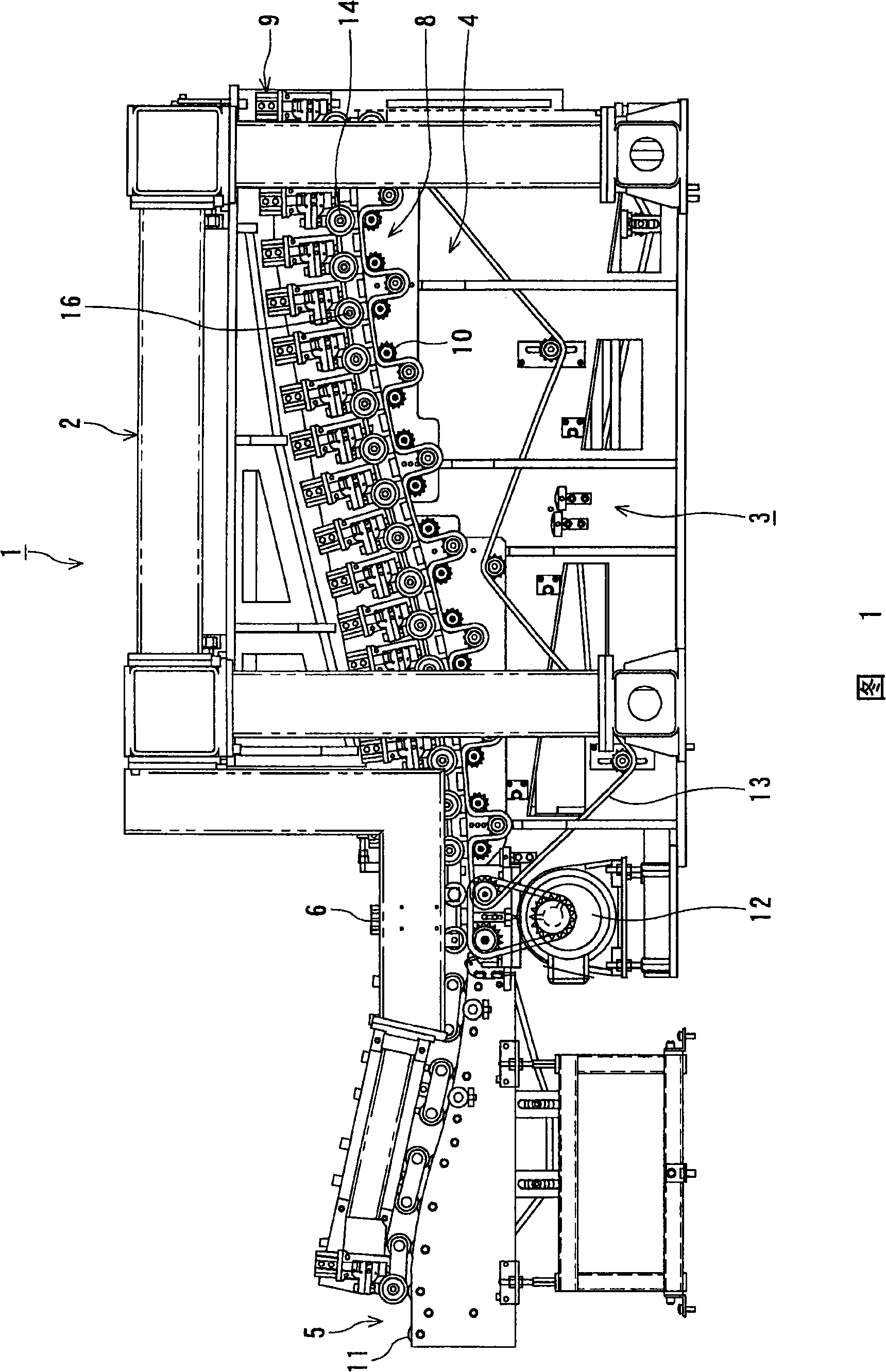

[0050] Fig. 1 shows a continuous welding apparatus to which the conveyor for sheet-like veneer (hereinafter it may be referred to as "sheet-like veneer conveyor" or simply "conveyor") of the present invention can be applied. equipment.

[0051] As shown in FIG. 1 , a continuous welding apparatus or machine 1 includes a sheet-like web conveyor 3 assembled to a frame 2 . The conveyor 3 mainly includes a load-in unit 4 and a load-out unit 5 for sheet-like veneers.

[0052] In this embodiment, a stationary laser welding machine 6 is used as welding instrument. A laser welding machine 6 is provided above and between the loadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com