Online continuous roller hole pattern misplacement detection instrument and method

A detector and roll technology, which is applied in the field of hot-rolled seamless steel pipes, can solve the problems of continuous roll pass misalignment, which are difficult to find and deal with, and achieve the effects of simple and reliable detection methods, improved wall thickness accuracy, and saving post-sequence adjustment work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

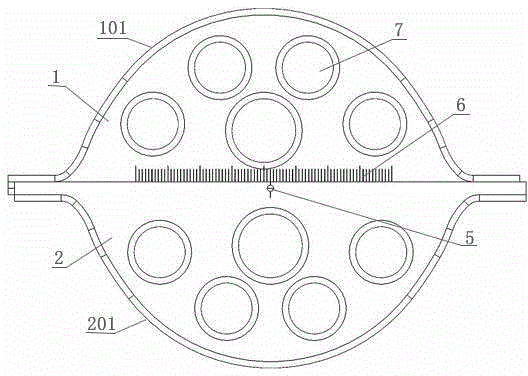

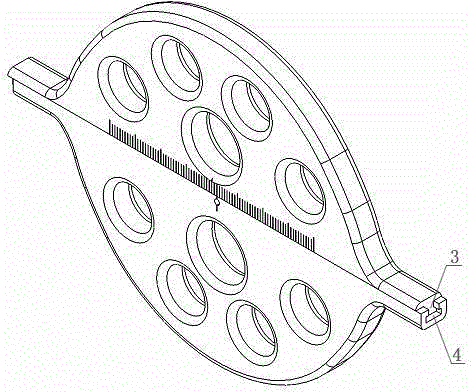

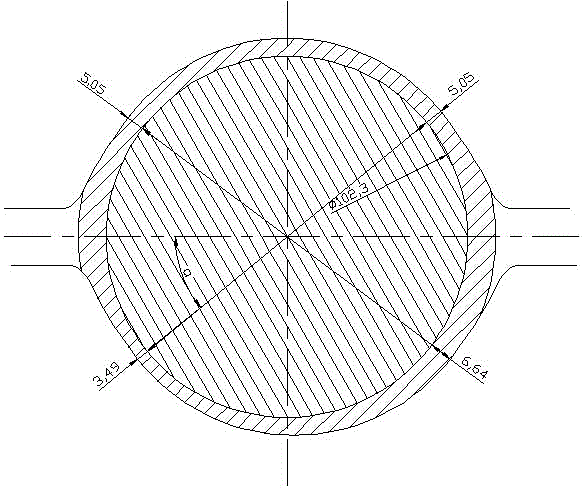

[0015] Such as Figure 1-Figure 2 As shown, the on-line continuous roll pass dislocation detector includes upper and lower pass samples 1, 2, the upper and lower pass samples 1, 2 respectively have partial arc surfaces 101, 201 corresponding to the continuous roll pass and The two together form the continuous roll pass. The contact surfaces of the upper and lower pass templates 1 and 2 adopt the cooperation form of the slider 3 and the slideway 4, and the two can slide relatively. A zero mark 5 is provided at the pass center of the lower pass pattern plate 2, and a reference scale mark 6 is provided on the upper pass pattern plate 1 corresponding to the zero mark 5, and the unit of the reference scale mark 6 is 1mm. There are a plurality of through holes 7 which are convenient to hold on the board surfaces of the upper and lower hole pattern templates 1 and 2 . The reference scale mark 6 is provided with a reference point corresponding to the zero mark 5 when no misalignment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com