Dust removal and dioxin decomposition integration filter material and preparation method thereof

A filter material and dioxin technology, applied in the field of dust removal and dioxin decomposition integrated filter material and its preparation, can solve the problems of reduced performance, catalyst fiber damage, low strength, etc., to reduce material costs and improve Catalytic efficiency, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

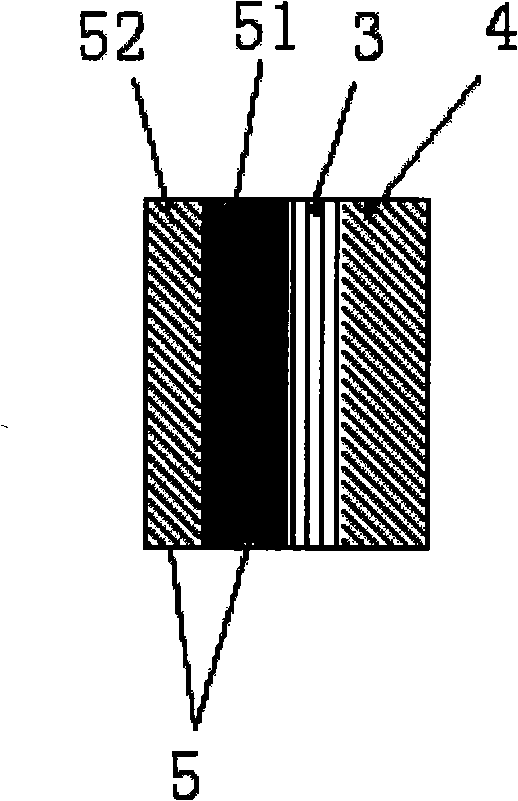

[0038] An integrated filter material for dust removal and dioxin decomposition, such as figure 1 shown. It includes a supporting catalytic layer 5, a base cloth layer 3 and a supporting layer 4, one side of the base cloth layer 3 is placed on one side of the supporting catalytic layer 5, and the other side of the base cloth layer 3 is placed on the supporting layer 4; the supporting catalytic layer 5 It consists of a catalytic layer 51 superimposed on a catalytic support layer 52 .

[0039] (supporting layer 4 and catalytic supporting layer 52 are all made by one or more mixing in polytetrafluoroethylene fiber, polyimide fiber, polyphenylene sulfide fiber, glass fiber, aramid fiber; In the present embodiment , the supporting layer 4 and the catalytic supporting layer 52 are made by mixing polytetrafluoroethylene fibers and polyimide fibers; the catalytic layer 51 is made of the catalytic film disclosed in the application number 200710069975.x; One or both of vinyl fluoride f...

Embodiment 2

[0050] In this embodiment, the arrangement of dust removal and dioxin decomposition integrated filter material is the same as that of Embodiment 1, see figure 1 shown.

[0051] The preparation method of the above dust removal and dioxin decomposition integrated filter material is as follows:

[0052] a. Preparation of support layer

[0053] The glass fiber fibers are opened, carded, laid, and needled through needle-punched nonwoven fabric processing equipment to prepare a catalytic support layer 52 and a support layer 4 with a grammage of 150 grams per square meter;

[0054] b. Preparation of supporting catalyst layer

[0055] Using the catalytic film disclosed in the application number 200710069975.x, by sewing machine quilting, 2 layers of catalytic film (total grammage is 500 grams per square meter) are fixed on the catalytic support layer 52, and reinforced into a support through acupuncture Catalytic layer 5;

[0056] c. Preparation of filter felt: place the supportin...

Embodiment 3

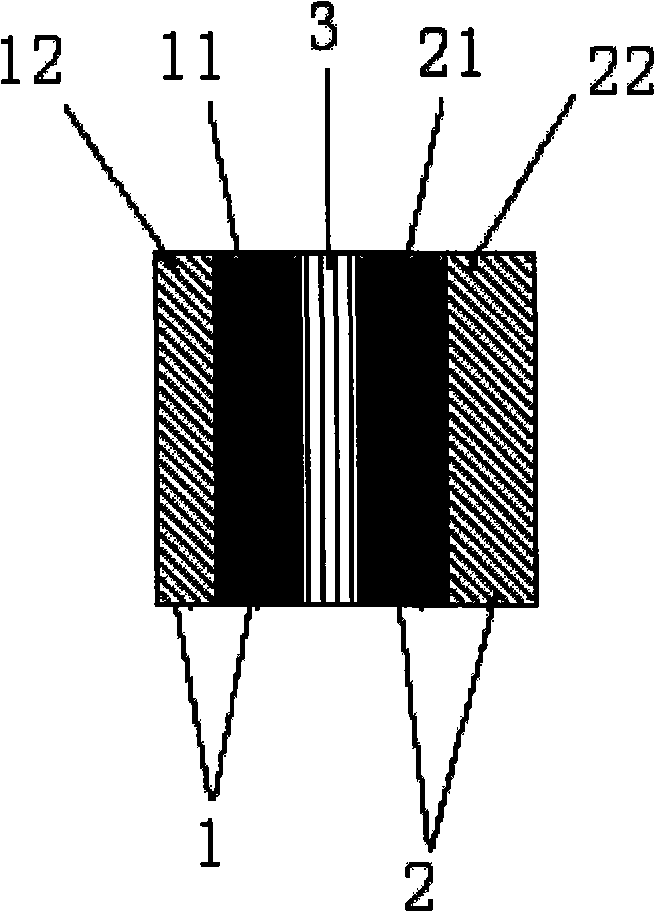

[0061] Another integrated filter material for dust removal and dioxin decomposition, such as figure 2 shown. The support layer 4 is replaced by a support catalyst layer, which includes two sets of support catalyst layers, namely support catalyst layer 1 and support catalyst layer 2 . The supporting catalytic layer 1 and the supporting catalytic layer 2 are placed on both sides of the base cloth layer 3 respectively. The supporting catalytic layer 1 is composed of a catalytic layer 11 superimposed on a catalytic supporting layer 12 ; the supporting catalytic layer 2 is composed of a catalytic layer 21 superimposed and covering on a catalytic supporting layer 22 . The base cloth layer 3 is disposed between the catalytic layer 11 and the catalytic layer 21 .

[0062] The preparation method of the above dust removal and dioxin decomposition integrated filter material is as follows:

[0063] a. Preparation of support layer

[0064] The polytetrafluoroethylene fiber is opened, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com