Cure tobacco leaf roasting aroma-extracting agent and use thereof

A technology of aroma enhancing agent and tobacco leaves, which is applied in the field of treatment of flue-cured tobacco leaves before baking, to achieve the effect of improving aroma, improving aroma, and increasing aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

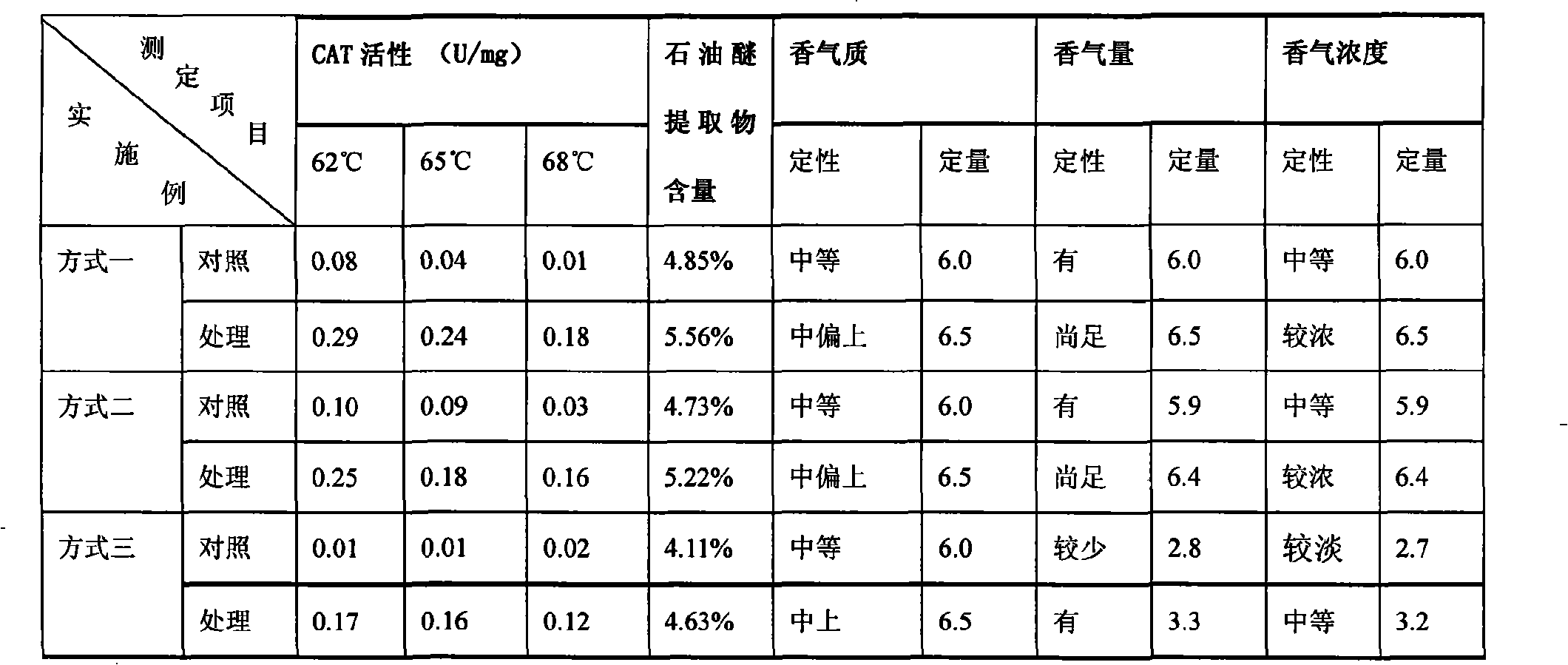

Embodiment 1

[0019] The weight percent content of each component of the flue-cured tobacco leaf roasting aroma enhancing agent is: 3.5% hydrogen peroxide, 3.5% acetic acid, 0.10% beta-methylpentanoic acid, 0.03% ethyl maltol and 92.87% water. According to the weight percentage content of the above components, the flue-cured tobacco leaf roasting flavoring agent is prepared. After preparation, the front and back sides of the mature and harvested tobacco leaves are evenly sprayed, and the spraying amount is 250g per hundred tobacco leaves. The test results are shown in Table 1. After the above treatment, the catalase activity in the tobacco leaves was higher than that of the control in the temperature range exceeding 60°C, and the petroleum ether extract content of the cured tobacco leaves increased by 0.71 percentage points; the sensory quality evaluation of the cured tobacco leaves was The aroma quality is increased from "medium" to "middle upper", the aroma amount is increased from "existe...

Embodiment 2

[0021] The weight percent content of each component of the flue-cured tobacco leaf roasting aroma enhancing agent is: 2.0% of hydrogen peroxide, 2.5% of acetic acid, 0.1% of β-methylpentanoic acid, 0.03% of ethyl maltol and 95.37% of water. According to the weight percentage of the above components, it is formulated into a flue-cured tobacco leaf roasting aroma enhancing agent. After preparation, it is evenly sprayed on the front and back of mature harvested tobacco leaves, and the spraying amount is 200g per hundred tobacco leaves. The test results are shown in Table 1. After the above treatment, the catalase activity in the tobacco leaves was higher than that of the control in the temperature range exceeding 60°C, and the petroleum ether extract content of the cured tobacco leaves increased by 0.49 percentage points; the sensory quality evaluation of the cured tobacco leaves was The aroma quality is increased from "medium" to "middle upper", the aroma amount is increased from...

Embodiment 3

[0023] The weight percent content of each component of the flue-cured tobacco leaf roasting aroma enhancing agent is: 3.0% hydrogen peroxide, 3.0% acetic acid, 0.1% 3-methylpentanoic acid, 0.03% ethyl maltol and 93.87% water. According to the weight percentage of the above components, it is formulated into a flue-cured tobacco leaf roasting aroma enhancing agent. After preparation, it is evenly sprayed on the front and back of mature harvested tobacco leaves, and the spraying amount is 220g per hundred tobacco leaves. The test results are shown in Table 1. After the above treatment, the catalase activity in the tobacco leaves was higher than that of the control in the temperature range exceeding 60°C, and the petroleum ether extract content of the cured tobacco leaves increased by 0.52 percentage points; the sensory quality evaluation of the cured tobacco leaves was Aroma quality increased from "medium" to "middle upper", aroma quantity increased from "less" to "existent", arom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com